TT Electronics - High Performance Technology for Valve Position Sensing

3D modelling of SIMPSpad for linear valve application

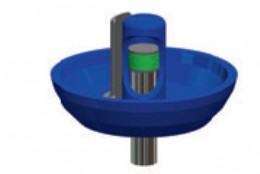

Autopad® sensor integrated into valve head application

Autopad®

Take Autopad® for instance. This position sensing system is used for linear and rotation sensing in a wide range of automotive applications - in over five million applications each year - and the same benefits can be enjoyed in modern valve design. The system can measure absolute or relative position with high resolution and accuracy. As each system is designed for the particular application, virtually any size or shape of valve can work with it, and in many cases it can be retro-fitted. Linear designs with travel of over 700mm have been created to date.

The particular features of Autopad® stem from its contactless inductive design that uses no magnets. This gives excellent immunity to EM interference and can operate through oil, water and plastic, vital for valves used in many process industries for example. It also ensures that the sensor is tolerant to vibration and offsets. The Autopad® design consists of two parts: a pad which is a specially built pcb incorporating transmitting coils, and a ‘target’ puck that typically connects to the moving part of the valve. These two components move relative to each other to create an output signal according to the puck position. The signal has 12-bit resolution, an accuracy of better than 1% and zero hysteresis. A digital signal can also be generated in different formats for interfacing with other equipment.

“Demand is now clear from valve manufacturers…”

Valve head

Demand is now clear from valve manufacturers who are finding that Autopad® is ideally suited to applications in water transport and distribution, dairy farming and many manufacturing and process industries. The systems can provide high performance at a significantly lower cost than current sensor systems. Peace of mind is assured from the field-proven design in even critical applications. Temperature range specified is -40 to 150 degreesC operation.

SIMPSpad

Building on the ASIC developed for Autopad®, a new contactless technology platform has been developed: SIMPSpad offers the ability to sense even through non-ferromagnetic metals as well as water, oil and plastics. In situations where the sensor unit is surrounded by metal or attached to a metal casing, SIMPSpad can produce accurate, reliable position sensing where other systems would struggle at best.

SIMPSpad also features greater pad / puck separation: 5-15mm is easily achievable, and has a high tolerance to changes in this spacing, for example as a result of vibration or in less rigid installations.

As with Autopad®, the movement of a puck near to a pcb incorporating both transmitter and receiver coils produces the required signal. In the case of SIMPSpad however, a layer of high permeability soft magnetic material is incorporated into the static pad, and so the sensor operates in magnetoinductive rather than purely inductive mode. The sensor can be simple and highly robust, ensuring extreme reliability.

Linear and curvi-linear designs are possible, and in valve applications a magnet is attached to the moving assembly, while the static sensor is located on the outer part of the valve assembly. With suitably sealed electronics, SIMPSpad can even be operated fully immersed. And unlike most other sensing systems, very long travel distances are possible, limited only by the length of the pcb.

Since only the position of the magnetic puck is important, and not the strength of the magnet itself, good electromagnetic immunity is achieved. Control of hysteresis is important in valve applications and SIMPSpad operates with typically 0.2% hysteresis over its entire length. Analogue and digital outputs (PWM, PAS, LIN etc.) are possible, with two or three-wire connections to automotive specifications.

Valve applications in long-travel situations can be tackled easily, while the intrinsic robustness of the design provides great flexibility to achieve sensing even in very small spaces.

Designers and potential users wanting the best choice of sensing technology for their valve application should contact TT electronics Technology who specialise in designs for even mission-critical applications. Their technology experts can advise on the optimum technology platform and develop a bespoke solution to many types of sensing requirement.

Where accurate, repeatable and reliable sensing is required for virtually any valve application, these technologies can fit the bill. Valve manufacturers now have an additional way to create competitive advantage, no matter which sector they specialise in. TT electronics Technology is part of the sensor division of the global TT electronics Group. It is recognised around the world for delivering ‘best in class’ sensor solutions to some of the toughest problems in the automotive sector, and now solves challenging problems in aerospace, medical, agricultural and industrial applications. The Company operates from bases in the UK, Germany, India and China and has a network of distributors providing support to customers worldwide.

Colin Astbury

Sales Manager Northern Europe

AB Elektronik - TT electronics Sensor Division

Tel: +44 (0)1223 875596

Published: 20th March 2013

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...