Saunders® Improves Glass Lined Valve Deliveries

Simplicity of design coupled with more than 85 years of innovation has resulted in the Saunders® diaphragm valve’s ability to handle a wider range of fluids than any other valve type, gaining an excellent reputation for versatility and reliability, and establishing a presence in every process industry sector.

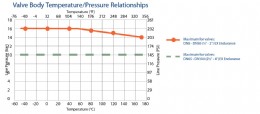

One product that has offered important benefits, and some challenges, to the industry since its introduction in the 1950s is the Saunders blue borosilicate glass lining option within its industrial diaphragm valves (IDV) product range. Considered the “Rolls-Royce” of valve lining options, the material demonstrates the best combination of corrosive and abrasive resistance of any valve offering. It offers exceptional high temperature resistance, to a maximum of 175 °C if coupled with the correct diaphragm grade such as the EX Endurance Diaphragm. This two-piece diaphragm consists of a wetted modified PTFE (TFM) face and non-wetted fabric reinforced Silicone rubber backing, and was specifically developed to provide best in class performance under elevated temperature applications.

While the benefits of this lining material are unmistakeable and offer excellent valve life, the Saunders borosilicate glass lining option is indeed a glass product which is notoriously fragile in nature. Therefore, it is most appropriate in environments that do not present the possibility of physical or thermal shock (i.e. rapid temperature changes, in service). Also, the glass-lining process is incredibly intricate and labour-intensive which poses challenges to manufacturers, especially in maintaining quality, fulfilling lead times and meeting promised delivery dates. Therefore there are not many that offer it. However, because of the product’s performance ability in some of the most challenging applications, and the low total cost of ownership versus expensive alloy alternatives, overall demand has not diminished significantly.

As one of the few global suppliers of this lining material, Saunders conducts a robust inspection and testing process to ensure only the most reliable and high quality products are delivered, offering in-field service when needed. Yet, the company has recognised its own shortcomings with respect to their customer service and has acknowledged the opportunity to improve.

Through close cooperation with external suppliers and through a process of continual improvement, the Saunders team has worked hard to identify and address many limitations within its processes. This improvement has been sustained through a robust cadence with stakeholders throughout the supply chain, and allows process quality failures to be absorbed with no impact to the customer. As a result, Saunders is pleased to announce an improved and consistent delivery performance for glass lined product (spare bodies and complete valves), with lead times in-line with customer requirements for this high end solution. Saunders welcomes further inquiries related to its glass lined product range, including queries related to suitable services (selected example application services listed opposite).

Glass Lining Properties

Nominal Lining Thickness: 1 mm

Size Range: Weir Style (A-Type): DN015-DN200

Straight Through Style (KB-Type): DN025-DN150

Temperature Range: -10 °C to + 175 °C

Pressure Range: Vacuum to 16 bar (size and diaphragm dependent)

Method of Operation: Manual or automatic with a variety of Saunders® brand actuators, including the ES Modular diaphragmtype and stainless steel S360 compact piston-type actuation ranges

Key Features of Glass Lined Valves

• Excellent combined corrosion and abrasion resistance

• Smooth flow – especially on viscous fluids

• High purity

• Economic value – lower priced than exotic alloys

• Interchangeability with existing Saunders® products including all diaphragms and topworks

Key Applications/Industries

• In Steel and other Metal Manufacturing Industries on strong pickling acid lines, typically up to temperatures of 60 °C

• Concentrated potassium chloride and sulfuric acid (up to 100%) utilised in Fertilizer Production

• Highly corrosive dry and wet chlorine gas at ambient temperatures (and suitable up to 150 °C) in the Pulp & Paper industry

• Abrasive paper stock with only 30-40% water, in the Pulp & Paper industry

Tel: +44 (0) 1633 486 666

Email: news@cranechempharma.com

Web: www.cranecpe.com

| Telephone: | 01633 486 666 |

| Email: | news@cranechempharma.com |

| Website: | www.cranecpe.com |

| More information on the Crane ChemPharma & Energy, Saunders BVAA Member Directory Page |

Search related valve / actuator articles: Crane ChemPharma & Energy, SaundersIssue 43Diaphragm Valves / Pinch ValvesCompany NewsMaterials