How SmartAct Plans to Save the World

Electric Motors consume around 48% of all the world’s electricity

The Smart Actuator Company presented a paper at the 2014 BVAA Conference to explain how the core RIFT Technology in their electric motor drives could give energy savings of 75% or more when compared to older design competitor products.

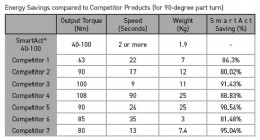

After 4 more years of sales and feedback from distributors and end user customers SmartAct® can back up the original bench testing results with practical field experience of the difference those energy savings can make to their customers. Some examples of the comparisons with competitors are shown on the table.

As well as the obvious electrical energy cost saving calculations there are often practical benefits such as the reduction in supply cabling specification to power the units and even the flexibility to be completely ‘off-grid’ and be supplied with power from solar panels and/or external battery storage.

How does the energy saving come about?

RIFT Technology uses the well-known and well understood science that generally small motors are more power dense than larger motors.

For most of us the most power dense motor we ever use is in our laptop or PC. If we are less fortunate it will be in our dentist drill when we are suffering in the chair!!

Combining small motors and collecting their torque output to a central shaft allows this greater power density to be utilised.

The possible Global benefits of RIFT Motor Technology

A disruptive technology capable of reducing electric motor energy consumption by 75% or more could reduce world electricity demand by more than a third.

This potential has brought about projects which the SmartAct® and the RIFT Driven® team are working in currently with a variety of partners to develop new products in the following applications,

- Electric Motors for Pumps

- Traction Drive Motors for Electric Utility Vehicles

- Small Wind Turbines

- Traction Drive Motors for Cars and Vans

By a simple maths calculation. If 48% of the world electricity is consumed by motors and RIFT Driven® motors could reduce that consumption by 75% or more then the world electricity need would drop by 36% if all those motors were converted to RIFT Technology designs.

The team at SmartAct®/RIFT Driven® have plenty of work ahead of them to help make this massive change to the world electricity demand.

Tel: 01684 565 709

Email: sales@smartact.co.uk

Web: www.smartact.co.uk

Published: 23rd August 2018

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...