Chinese pipeline selects Rotork ELB for increased line break safety

The Rotork Electronic Line Break (ELB) is a robust, selfcontained system that combines pipeline pressure monitoring with intelligent valve control

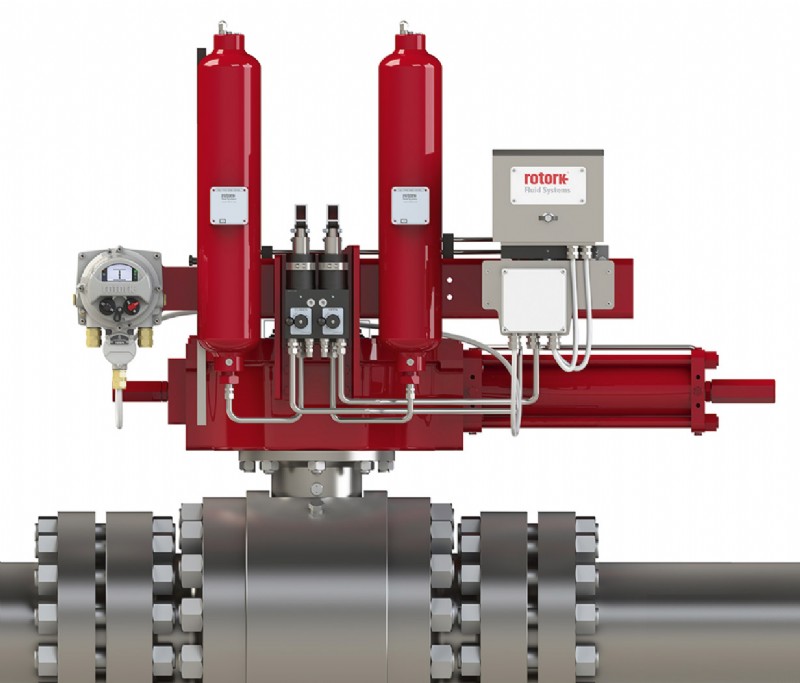

Rotork GO actuator fitted with ELB as supplied to the Chinese natural gas pipeline to provide increased line break safety

In one recent contract Rotork GO (Gas-over-Oil) pipeline actuators have been fitted with ELB units for line break monitoring and protection on remotely installed valves on a natural gas pipeline in China. The ELBs will enable the operator to monitor the running condition of the gas pipeline and the open/closed status of the valves. The immediate reporting of a line break by an ELB will enable the operator to swiftly close the appropriate valves and isolate the problem.

The ELB is housed in a compact, environmentally sealed and explosionproof housing that can be mounted on the actuator or remotely. Valve actuator control - selectable as fail close, fail open or stay put - is based on Rate-of-Drop (RoD) and Rate-of-Rise (RoR) of the pipeline pressure as well as high and low pressure limits. A remote Process Shut Down (PSD) input with the option to override all functions is also available to drive the valve to the predetermined fail position.

The ELB also provides an array of programmable alarm and alert indications and has an extensive range of features that can be configured to meet end users’ specific requirements. These include up to six remote inputs and four configurable solenoid outputs, Partial Stroke Testing (PST) and Modbus® network connectivity.

Setting menus displayed on the large HMI window are the focus for non-intrusive programming and commissioning using Rotork IQ intelligent electric actuation technology. In normal mode the LCD display indicates valve position. The same window also displays visual indication of status, alarms, event, trend and operation logs and diagnostic data.

Tel: +44(0)113 256 7922

Email: information@rotork.com

Web: www.rotork.com

Published: 23rd August 2018

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...