Langley Alloys to develop UK market for stainless steel hollow bar in partnership with Sandvik

Machining from hollow bar can significantly increase productivity

Around 80 different sizes of hollow bar are currently in stock

In house cutting-to-length to your exact requirements

Large diameter hollow bars destined for pump and valve manufacture

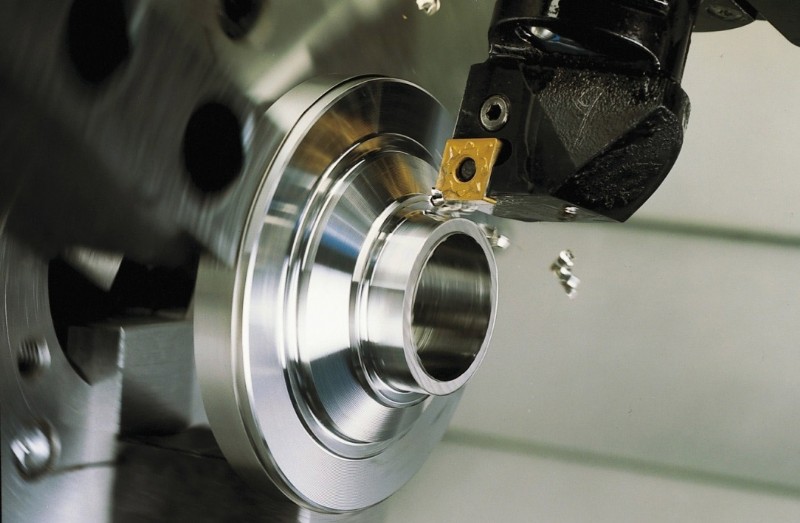

Hollow bars or bored bars allow machinists to significantly increase productivity, reducing the time needed to remove material for parts with a large internal diameter. This approach is particularly appropriate for the manufacture of mechanical seals, valve bodies, flow meters, pumps, and associated components for the oil and gas sector.

By starting with a near-net shape hollow bar, less metal is lost as low-value swarf and obviously less tooling is consumed too. Therefore, there can be immediate input cost savings when using this more sophisticated product form.

More significantly, reducing machining time or totally eliminating machining steps can dramatically improve productivity. This can either be valued as reduced machining time or cost for a given part, or also as higher throughput when machines are fully-loaded.

Finally, replacing solid bar with hollow bar eliminates the need for trepanning when producing components with a central bore, which causes material to work harden and is detrimental to subsequent machining operations.

The final benefit of our hollow bar stock range is that it exploits the Sanmac® alloy, where enhanced machinability comes as standard. The Sanmac® alloy specification carefully controls the non-metallic inclusions; sulphides encourage easier machining whilst oxide inclusions improve chip breaking. This helps to reduce tool wear and increase cutting speeds, resulting in significant cost reductions per produced item.

In order to unlock these opportunities from hollow bar for our customers, Langley Alloys has already stocked almost 80 different sizes (combinations of OD and ID) in Sanmac® 316L. This range will be progressively extended to include other sizes plus Sanmac® 2205. However, the potential to produce bespoke sizes and in super duplex and high nickel alloys also exists.

Tel: 01782 610 250

Email: sales@langleyalloys.com

Web: www.langleyalloys.com

| Telephone: | 01782 610250 |

| Email: | sales@langleyalloys.com |

| Website: | www.langleyalloys.com |

| More information on the Langley Alloys Limited BVAA Member Directory Page |

Search related valve / actuator articles: Langley Alloys LimitedIssue 47Related ProductsMaterials