Weir Valves & Controls Blakeborough -X-Stream Varistage Trim at Keadby Power Station, UK

When filling the boiler on a power station, there is generally a high pressure at the valve inlet, but a low outlet pressure, often only 1 BAR. This condition would result in severe cavitation if a single stage trim were to be applied. Using the X-Stream trim the pressure drop is staged across the cage which prevents the static pressure falling below the vapour pressure, thus eliminating cavitation and protecting the valve and the trim from damage.

When the plant is running, the boiler is charged and the feedwater valve is required to maintain the water flowrate into the boiler. This condition would normally require relatively high pressures, but relatively low pressure drops resulting in high water flow rates.

Historically, power stations would be built with two valves working in split range operation, one on boiler fill designed to control cavitation and one for normal operation to control flow. The demand for cost reduction in power station construction now means that engineers are demanding one control valve to fulfil both these applications.

To specifically address this application, Blakeborough has developed the X-Stream Varistage trim. This trim has been designed using the patented X-Stream disc stack at the bottom of the trim to control low valve Cvs and eliminate cavitation, but at higher valve openings the valve trim is designed with a more standard multi-flow trim to obtain the flow capacity.

The X-Stream Varistage trim is currently being applied to an existing valve at Keadby Power Station which has suffered from flow erosion. To reduce the costs of the application the trim was designed to fit in the existing valve body meaning that the trim could be fitting during a one day shutdown rather than having to shut down the station for an extended period to cut the existing valve out of the line.

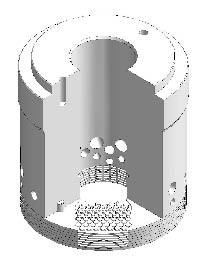

A sectioned view of the X-Stream Varistage. The lower section of the trim is designed with 8 discs stacked together and vacuum welded onto a multi-flow cage.

Contact: Marcus Williams Tel: 00 44 121 782 8888 Fax: 00 44 121 782 2875 Email: marcus.williams@uk.cevalogistics.com

Published: 25th September 2009

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...