Leengate Valves has seen further expansion in 2019

Leengate Valves has seen further expansion & revision in 2019. Continuing to maintain a strong chain of supply to the UK, despite uncertain times

Leengate Valves’ already vast storage space has seen the addition of around 160 pallet spaces; now taking their total to over 1000 pallet locations fully stocked with everything you need – not to mention thousands of locations for smaller, nonpalletized items.

Continuing to maintain a strong chain of supply to the UK market, despite uncertain times, Leengate are stepping up to reassure its distributors that their decades of hard work and dedication means that they will continue to offer the same level of service and availability that the market has come to expect.

Sales Director, Mick, said, “Maintaining a mutually-beneficial and fair relationship with our suppliers and manufacturers has always been of paramount importance to us. We’re certain that the strong relationships we have worked so hard to build will benefit our customers for years to come.”

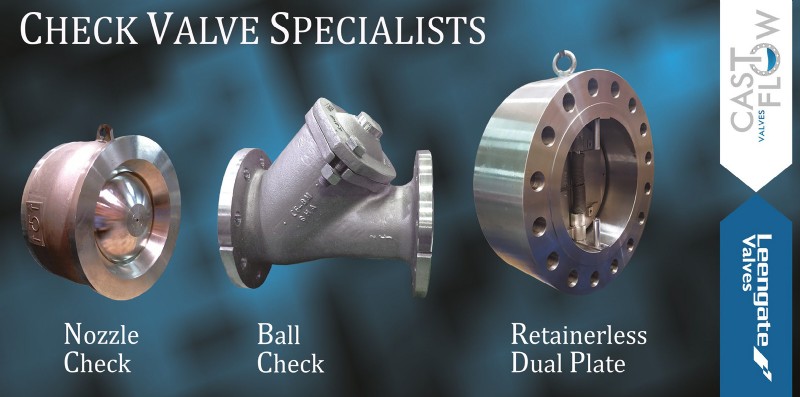

Always proud to promote their manufacturer’s product branding, Leengate Valves are continuing to increase awareness and visibility of their many worldwide manufacturers and, keen to continue its tradition, Leengate have collaborated with their manufacturing partner of 15 years, CASTFLOW VALVES, for this editorial submission.

Spanish manufacturing partner CASTFLOW VALVES specializes in check valves, covering DN25 (1 ̋ ) to DN1400 (56 ̋ ) sizes to suit a variety of flange connections including PN10, 16, 25 & 40 as well as ANSI 150 and 300.

As well as their many connection options, CASTFLOW manufacture valves in many different materials, including, Iron, Steel, Stainless Steel, Super Duplex and other special alloys.

Technical support for CASTFLOW valves is impeccable and distributors can rely on the CASTFLOW and Leengate Valves’ teams to ensure that the most suitable valve and material are selected for your application.

Already a major player in the worldwide industrial valve market, CASTFLOW’s continued growth has seen them develop improved rubber lined check valves for applications with corrosive fluids. Their retainer-less rubber lined check valve design guarantees a drop tight valve without weak areas that normal rubber lined valves can present.

CASTFLOW continuously develops new products depending on the needs of the market and encourage close collaboration with Leengate Valves in the UK and beyond. If there are any CASTFLOW valves you would like to hear more about call Leengate Valves on 01773 521555 or email info@leengatevalves.co.uk

Tel: 01773 521 555

Email: info@leengatevalves.co.uk

Web: www.leengatevalves.co.uk

Published: 29th April 2019

Rachel Wormald, Managing Director at YPS Valves Ltd and Elizabeth Waterman, ...

Are you looking for industry-leading, brand independent valve and actuator ...

As can be seen from the photograph, clearly the resident birds at Bartlett ...

Howco Group has unveiled its latest £1million investment, with the ...

In 2024, Allvalves is poised for an exciting year of growth and expansion, ...

GMM Pfaudler Engineered Plastics & Gaskets are delighted to bring the ...

In the ever-evolving valve industry, GMM Pfaudler stands out for its ...

SAMSON Controls Ltd – part of the SAMSON group - a renowned leader in ...