HSP Valves Rises to Wild Well’s Challenge 3,000 Metres Down

- HSP and Wild Well collaborate to upgrade ROV panels on a blow-out preventer capping system.

- HSP design, procure, build, and test panels to ensure operational stability 3,000 metres below the surface.

- Working to some challenging timelines, HSP’s team met Wild Well’s internal project schedule and requirements.

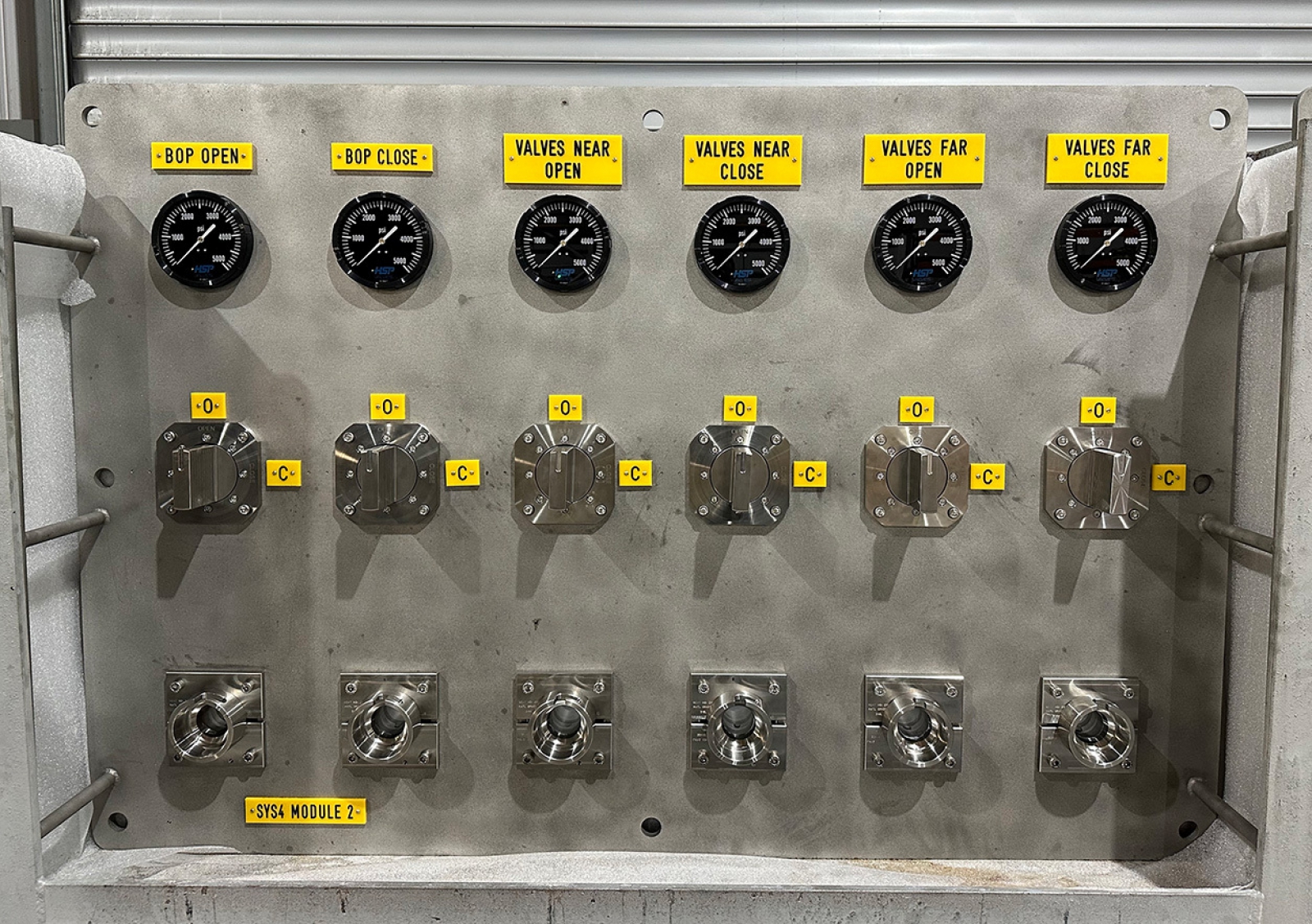

HSP Valves, a leading valve supplier to EPCs, OEMs, and end-customers has recently completed an upgrade on the ROV panels of a subsea blow-out preventer (BOP) capping system for Wild Well, one of the world’s most recognised names in on and offshore well control.

HSP was commissioned to design, procure, build, and test the panels to ensure complete operational stability in a subsea environment 3,000 metres below the surface. At these depths, the external pressure can be up to 300 atmospheres (4,500 psi).

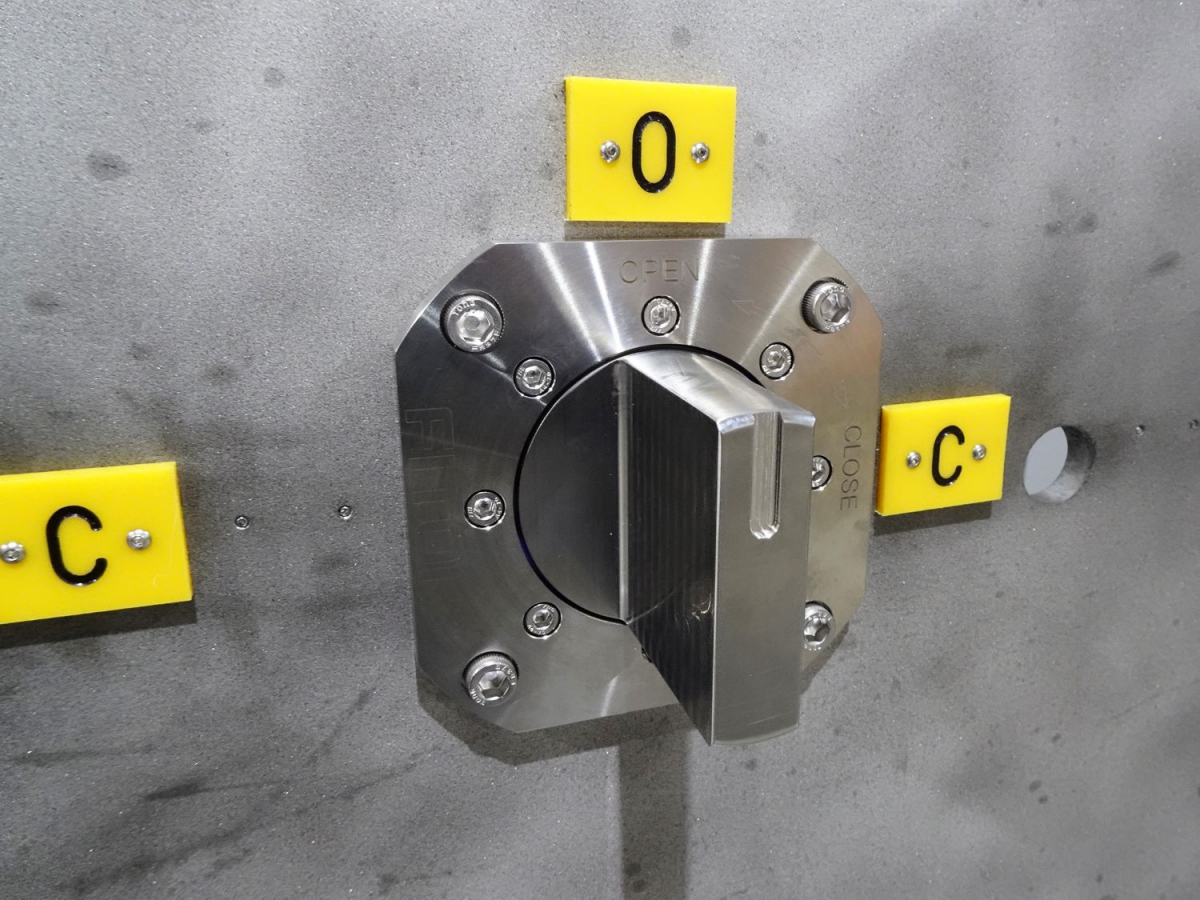

Designing the panels to operate at these extreme depths required additional considerations compared to onshore or topside design, including external pressures exerted on the equipment. Submersible remotely operated vehicles (ROVs) are used to operate the system subsea, so this also required careful consideration during the design stage to ensure easy operation of valves.

BOPs are incredibly important to offshore drilling, enabling valves to be operated manually or remotely to shut off the flow of fluids if a well is compromised in any way. This not only protects the lives of those on the rig on the sea’s surface, but also prevents environmental harm.

BOP failure, and the resultant loss of life and environmental damage, has been well documented. But as oil and gas exploration goes to ever-deeper waters, in more unforgiving environments, and in increasingly remote locations, the safe and reliable performance of BOP systems continues to be a key priority.

HSP’s team worked closely with Wild Well to capture their specific requirements, before creating detailed designs of the panels in their main facility in Aberdeen. Following successful test, inspection, and delivery to the client, the ROV panels were installed and connected to the BOP stack assembly.

Derrick Mackenzie, HSP’s Managing Director, commented, “The project required our team to respond to some fairly challenging project timelines. It shows our ability to work effectively and efficiently together, and individually, that ensured Wild Well’s internal project schedule and requirements were met”.

Meanwhile, HSP is looking forward to developing more installation and commissioning opportunities in the subsea environment in 2024.

Tel No: +44(0)1635 201 329

Email: sales@hsp-valves.com

Website: https://www.hspvalves.com

Published: 28th February 2024

Valveuser Magazine Issue 91 is the first of our Special Print Editions for ...

BVAA’s Director Rob Bartlett comments, “In 2024, the BVAA will be ...

Spring Conference & Golf Day, 22-23 May 2024 at Mottram Hall, ...

As 2024 is BVAA’s 85th Anniversary year, I recently had the perfect ...

The international event of reference for industrial valves and flow control ...

As long-term readers of Valveuser will know; Heap & Partners Ltd was ...

WIRRAL manufacturer Heap & Partners has recently celebrated one hundred ...

IMI has announced a record year for orders throughout the hydrogen value chain ...