Cost Reductions Achieved by Valve Condition and Performance Monitoring

Part Two: V-MAP® G3 and MIDAS® Sensor

To read more about Score’s approach to this problem, please see part one of this article on page 36.

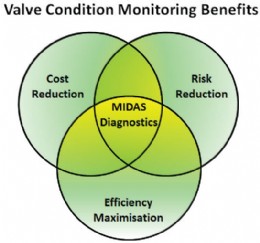

The MIDAS® range of valve condition and performance monitoring equipment and systems allow you to safely, efficiently and effectively ensure that your proactive and predictive maintenance interventions are all completed “with cause” and are fully focused and prioritised.

The net effect of taking this approach to investing your maintenance budget is minimum costs for maximum impact/ return on investment – i.e. cost reductions with the added bonus of more reliable and efficient production, which in turn maximises profits.

In a cost-base sensitive marketplace, who would not want that?

In this, part 2 of Score’s overview of the MIDAS® and V-MAP® Valve Monitoring range, we examine options which provide permanently installed and fully integrated valve monitoring solutions.

A Permanently Installed, Intrinsically Safe Certified, Acoustic Emissions (AE) Valve Condition Monitoring Device

Non-Invasively Monitor and Display, Quantify and Trend Through Valve Leaks via a DCS/SCADA/Other Graphic User Interface

For more critical process valves, the MIDAS® Sensor (patent pending) has been developed to be installed directly on the valve and adjoining pipework, to give a continuous and permanent feedback indication of isolating valves’ sealing performance in line. The sensor used is the same design as the MIDAS Meter® and the output from the unit’s acoustic emissions (AE) sensor (a standard 4-20mA electrical signal) is designed to tie in directly with all plant’s Digital Control Systems (DCS), or Supervisory Control And Data Acquisition (SCADA) Systems, or Score’s own V-MAP® G3 System. This device is ideal for customers looking to monitor flare-line losses through isolating and pressure relief valves.

Fully Integrated Critical Valve Condition and Performance Monitoring System

Monitor performance against prescribed standards and trend Valve and Operator Performance over time. Report Indicators of any/all Developing Failure Modes

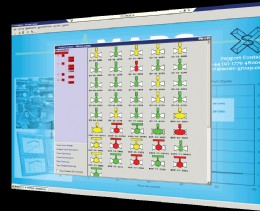

For the most critical process valves, such as Emergency Shutdown Valves (ESDVs), Blow Down Valves (BDVs) and High Integrity Pressure Protection Systems Valves (HIPPS), where failure modes and effects other than basic through-seat leakage are important to monitor and trend, Score have developed a fully integrated, permanently installed system known as V-MAP® G3. The system, comprising sensors, instrumentation, and bespoke in-house manufactured data acquisition and signal processing equipment and software, as well as management/reporting software, continuously monitors all planned and unplanned valve strokes. Key indicators of valve and operator performance over time are reported in both statistical and graphical formats for further analysis. This system is ideal for customers looking to monitor the most critical valves in the process to ensure risks to personnel, plant, the environment and process losses are minimised.

V-MAP® Case Study:-

Customer installed the V-MAP® system on 41 critical valves, with the aim of minimising the number of personnel interventions and process disruptions required at the plant for monitoring activities, whilst also maintaining the optimum level of safety integrity. This approach effectively assured the reliability of these critical valves and guided all maintenance activities, based on its analysis of current valve condition and performance.

As a result of the V-MAP® system reliably delivering the required added value, the customer made the decision to expand and install the system on a further 20 critical valves as part of the site expansion programme.

Full details of this and more case studies can be supplied on request.

Score Group plc / Score Diagnostics Limited

Tel: 01779 480 000

Web: www.score-group.com

| Telephone: | 01779 480000 |

| Email: | Europeafrica@score-group.com |

| Website: | www.score-group.com |

| More information on the Score BVAA Member Directory Page |

Search related articles: ScoreIssue 34Valve Repair and Service