IMI Critical Valve Doctor® team solves plant trip issues at CCPP in the Americas

IMI CCI RSM in California is an IMI Critical Engineering centre for excellence and is the technology centre for DRAG® control valves

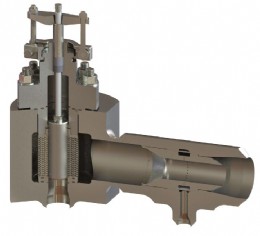

100D bypass valve with venturi desuperheater

100DSV spraywater valve

An IMI CCI customer operating two 1100MW combined cycle power plants was facing issues with repeated turbine trips leading to significant losses. Upon investigation, the customer discovered that the original plant design did not account for the maximum steam flow rates produced during duct burning. This design led to undersized bypass valves which resulted in over-pressurising of the high-pressure (HP) drum and turbine trips. The customer and original Engineering, Procurement & Consulting (EPC) firm approached IMI CCI to provide a solution with minimal impact to the existing pipe configuration within a challenging lead time.

The solution

IMI CCI Valve Doctors® reviewed the actual process conditions using distributed control system (DCS) data and the customer piping layout. The team proposed a new HP-to-cold-reheat (CRH) bypass line in parallel with the existing line, which contained an IMI CCI DRAG® valve. The new bypass valve would operate over the first 30% of the bypass flow, after which the existing bypass valve would supplement the new valve. IMI CCI proposed the 100D DRAG® valve with the new style venturi desuperheater.

This valve will meet the challenging operating conditions of very low flows, outlet velocities, and the pressure differential between spraywater and steam outlet. The venturi desuperheater is specifically designed to provide effective steam atomisation and desuperheating in low kinetic energy applications and features a no-weld design. This reduces the possibility of pipe cracking and, increases design life and serviceability. Additionally, when coupled with the 100DSV DRAG® spraywater control valve and IMI Zikesch water isolation and check valves, IMI CCI was able to provide a single vendor system solution.

With the use of innovative product designs and a broad of valve solutions, IMI CCI was able to provide a complete system solution to meet the tough performance demands of the applications.

Valve Doctors®

IMI Critical’s acclaimed Valve Doctors® are at their customers’ disposal to solve process flow problems in power, nuclear, oil & gas and petrochemical plants around the world. IMI Critical Engineering Valve Doctors® complete a comprehensive 7-year programme including valve design, plant operation, system layout and control system integration. Since the program’s inception in 2000, there are now 65 engineers to have achieved Valve Doctor® accreditation, with a further 70 in the training program. The Valve Doctor® program was originally conceived as a way of increasing the interaction between IMI Critical’s top technical experts and customers with demanding engineering challenges. It has since become an established mentoring and development program, which helps the company attract and retain some of the best engineers in the business.

More upgrade solutions!

You can read about more of the great solutions provided by the Valve Doctor® team and other highly skilled IMI Critical engineers on our website www.imi-critical.com/case-studies.

Email: imicci.sales@imi-critical.com

Web: www.imi-critical.com

| Telephone: | 0121 7173700 |

| Email: | imihq@imi.critical.com |

| Website: | www.imi-critical.com |

| More information on the IMI Process Automation BVAA Member Directory Page |

Search related articles: IMI Process AutomationIssue 49Repair and ServiceValve Repair and ServiceActuator Repair and Service