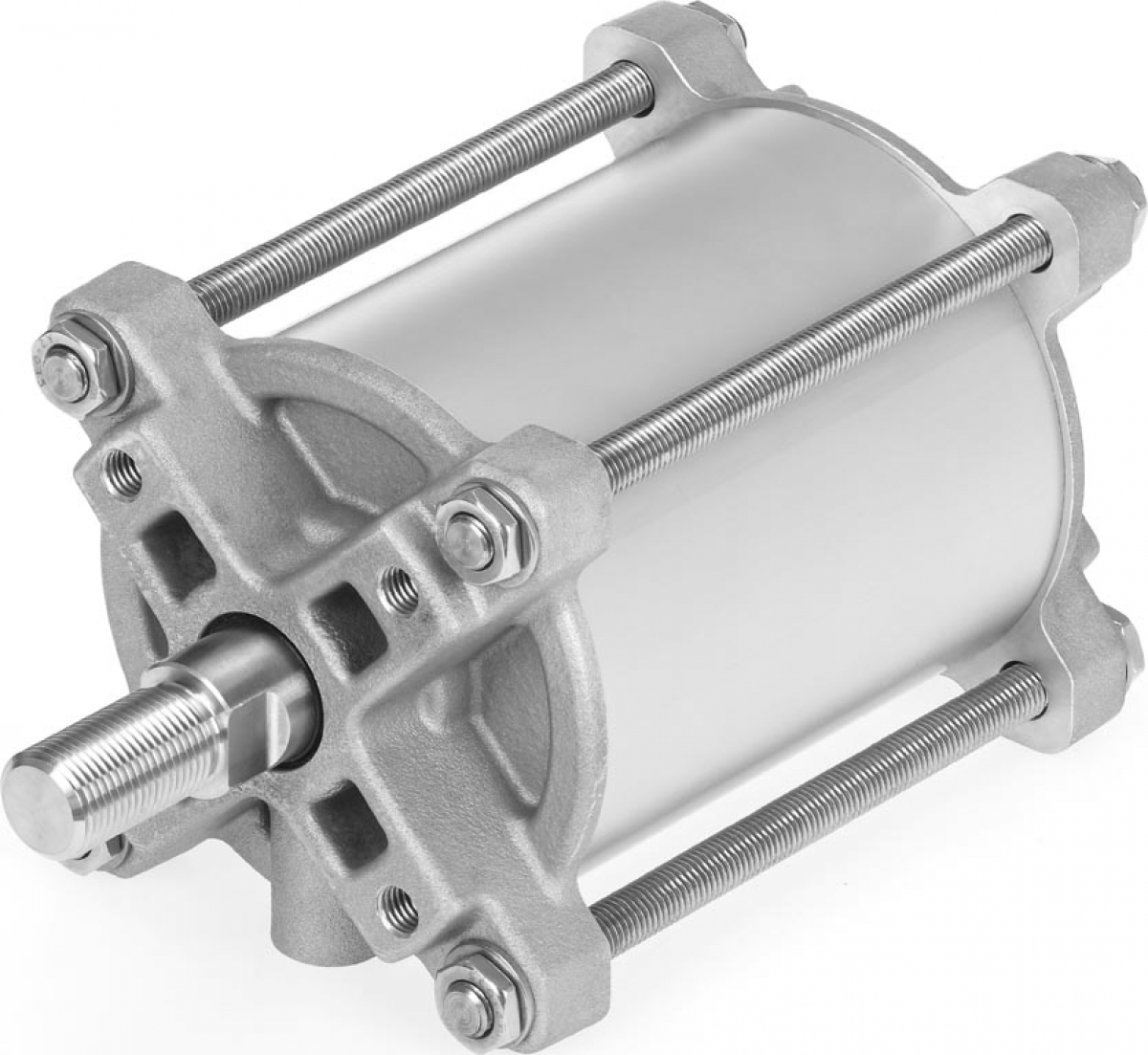

Festo: Pneumatic actuator with a wealth of variants

Sturdy and durable linear actuator DFPC from Festo

Freedom of choice: The double-acting pneumatic linear actuator DFPC from Festo for process valves is available either as low-cost, preconfigured standard variants from stock or as individually configured versions. (Photo: Festo SE & Co. KG)

The double-acting pneumatic linear actuator DFPC from Festo gives users in water technology, mining and power stations as well as the paper and cellulose or steel industries freedom of choice. They can order the actuator for process valves such as slide and knife gate valves or pinch valves or process valves without a housing, either as low-cost, preconfigured standard variants from stock or as individually configured versions.

Users can choose from low-cost, predefined standard variants that are available quickly from stock or opt for individual configurations of stroke, length of the spacer bolts at the bearing cap, piston rods of differing lengths, thread types and diameters as well as SIL certification, if required.

Long actuator life

The one thing all the different versions have in common is the sturdy and durable design of the pneumatic actuator DFPC. The piston rod, screws, nuts and tie rods are made of stainless steel, while the barrel and end caps are made of aluminium; this ensures that the actuators have a long service life. The end-position cushioning on both sides enables high travel speeds while optional proximity sensors permit reliable end-position detection. An external displacement encoder is available for more detailed information about the actual actuator position.

Pneumatic actuators have proven to be shock-proof and durable since, in contrast to electric actuators, they are made up of a small number of components and are thus less likely to break down. Pneumatic actuators are also resistant to continuous loads and remain maintenance-free over their entire service life. With an average service life of up to 1 million switching cycles, they will outlast any process valve. This is true even in harsh environments in process industries where high temperature differences, contamination and humidity can occur.

Benefits of pneumatics

Deposits or caking can result in significantly increased breakaway torques. This is particularly the case if process valves are actuated infrequently or not at all for long periods of time. This is often the case in wastewater treatment plants, for example. The overload protection offered by pneumatic actuators is a major advantage here. This is because pneumatic components enable the operating pressure and thus the power to be increased without any problems. They can withstand high loads even at standstill without incurring any damage and have large power reserves for overcoming higher breakaway torques.

Pneumatic actuators also offer advantages over electric drive technology when used in ATEX zones. In the ATEX zone, the actuators are supplied with compressed air via tubing while the control electronics are installed in non-hazardous areas. Pneumatic actuators are ATEX-approved up to zone 1 as standard.

| Telephone: | 0800 626422 |

| Email: | info.gb@festo.com |

| Website: | www.festo.com |

| More information on the Festo Ltd BVAA Member Directory Page |

Search related articles: Festo LtdIssue 57Pneumatic Actuators