Your One-Stop Shop For Hydrogen Applications - ARI is H2-ready!

Valves for the Entire Hydrogen Value Chain

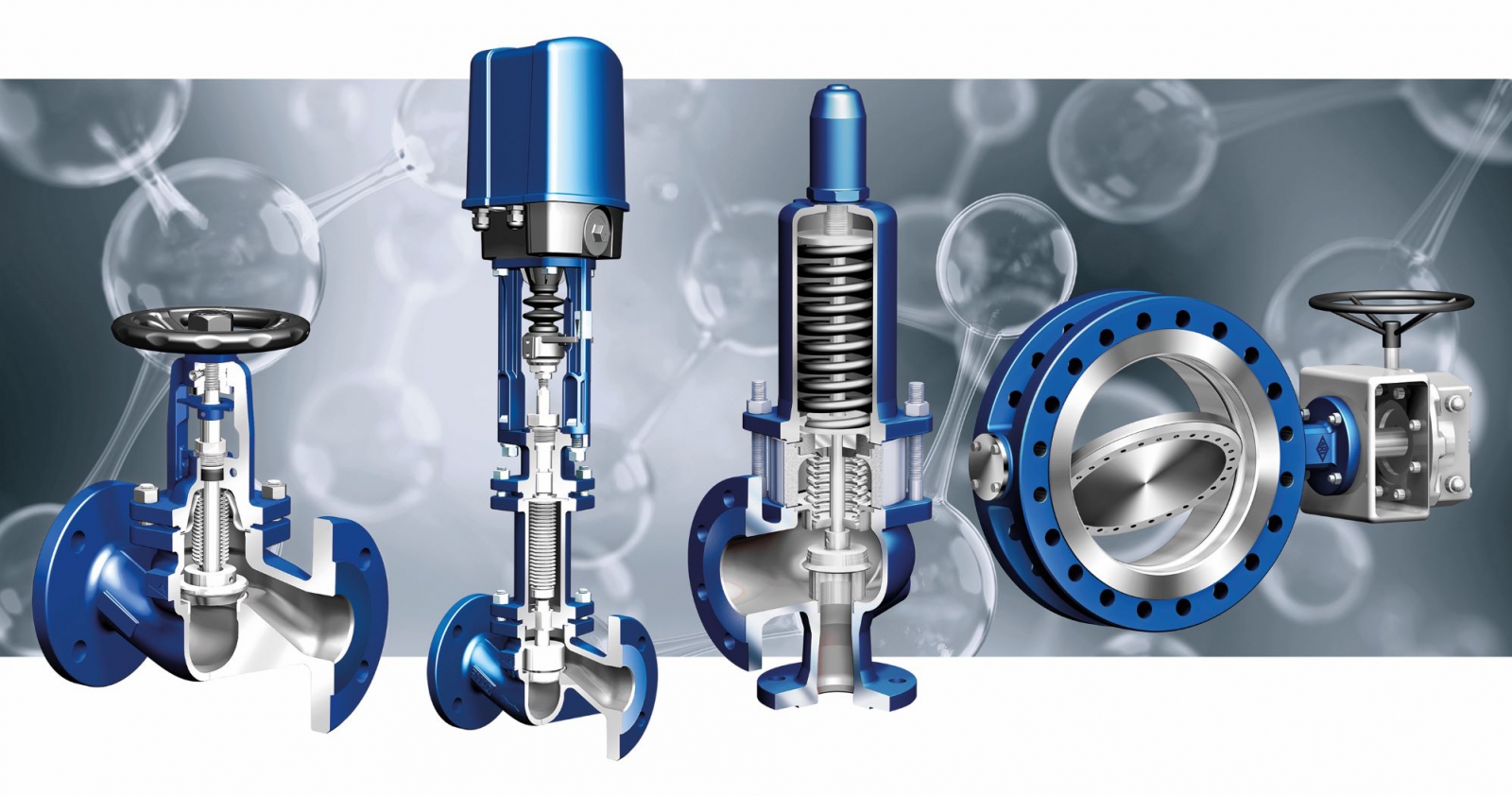

ARI-Armaturen Hydrogen Products

ARI-ZETRIX

ARI-SAFE/REYCO

ARI-STEVI

Valve Design for Use in Hydrogen Applications

Hydrogen is considered to be a versatile energy carrier of the future that does not emit direct greenhouse gases in use. As we move towards a decarbonised environment, potentially green, climate-neutral technologies are becoming also economically more attractive. Great hopes rest on green hydrogen as a versatile energy carrier that neither during production, nor in use, emits greenhouse gases that are harmful to the climate.

At the same time, hydrogen places high demands on valves and its high gravimetric energy density and can lead to material embrittlement under certain conditions.

ARI-Armaturen has a broad portfolio of valves for control, isolation, safety and steam trapping and can supply valve solutions for the entire hydrogen value chain. This applies both to hydrogen directly and to other media such as coolants, demineralised water, saturated steam, oxygen & heat transfer oils.

The Right Valve for Your Hydrogen Application

As the lightest of all elements, hydrogen atoms can diffuse through the crystal lattice of steel and be a cause of material embrittlement. High-strength carbon steels have been shown to be particularly susceptible to this and are therefore not recommended. Austenitic stainless steels like those used by ARI-Armaturen, on the other hand, have proven to be suitable materials. Examples: 1.4408 (CF8M) and 1.4581 (CF10M) as cast materials or 1.4404 (316L) and 1.4571 (316Ti) for the internals. Especially at high temperatures, material selection needs to be tailored to the specific operating and design conditions. Since hydrogen is highly volatile, very strict requirements apply to internal — and even more so to external — leak-tightness.

ARI-ZETRIX

Triple offset process valve for challenging applications DN 80-1400, 3”-56”, PN 10-100 Class 150-600 , -60 °C to +550 °C

• Reliably tight due to offset disc design (maximum closing force, minimum effort). Design: EN 12516, ASME B16.34, API 609

• Approvals: Firesafe, ISO 15848-1 / TA Luft, SIL, ATEX, EAC

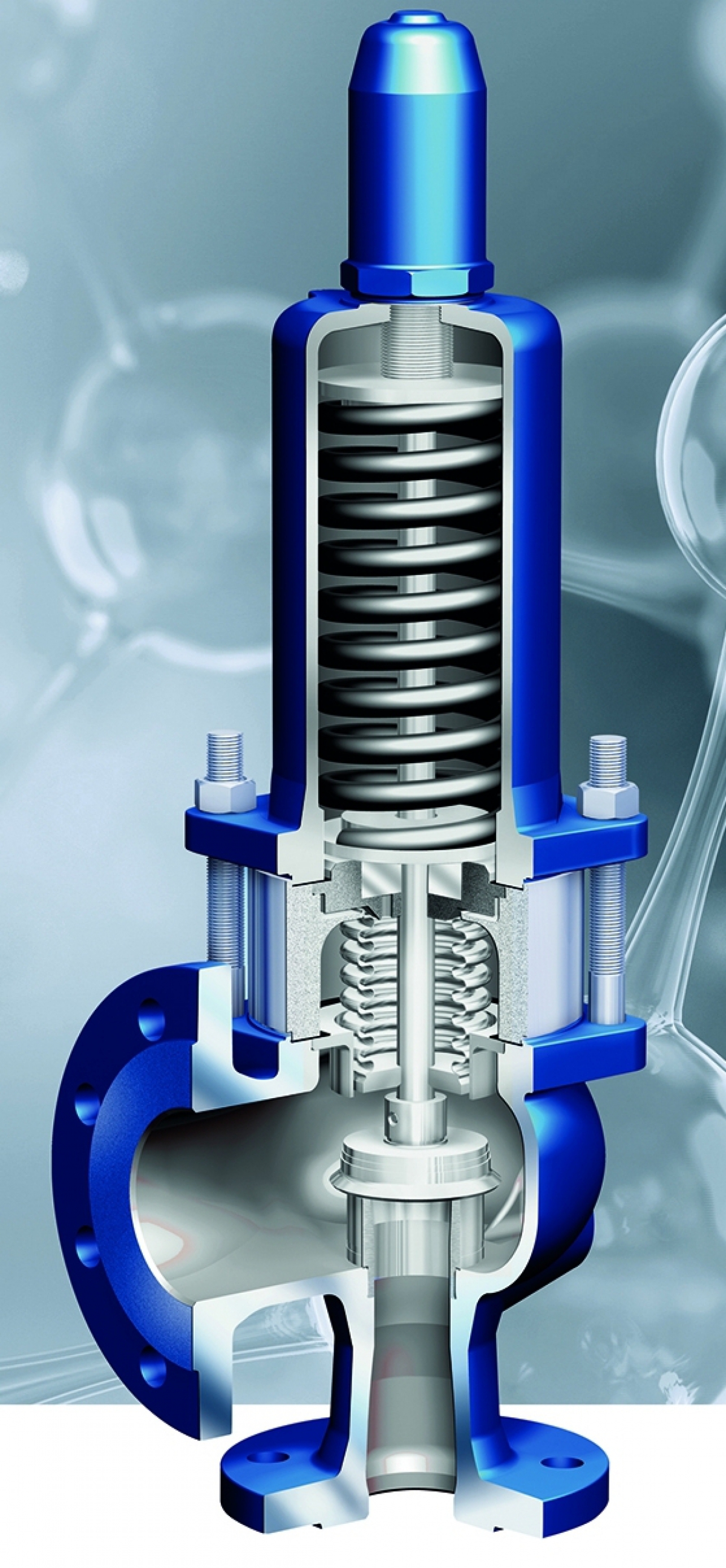

ARI-SAFE/REYCO

Direct acting safety valves acc. EN (SAFE) and ASME/API (REYCO®). DN 15-250 / NPS ½”-8” | PN 16-100 / Class 150-2500 | -60 °C to +450 °C (SAFE) | -196 °C to +538 °C (REYCO®)

• Fulfils tightness requirements acc. ISO 15848-1

• SAFE: Type approved acc. ISO 4126-1, VdTÜV 100, TRD, AD2000-A2, ASME Sec. XIII (formerly Sec. VIII)

• REYCO®: Type approved acc. ASME Code Sec. XIII (formerly Sec. VIII), API 526 and certified acc. ISO 4126-1

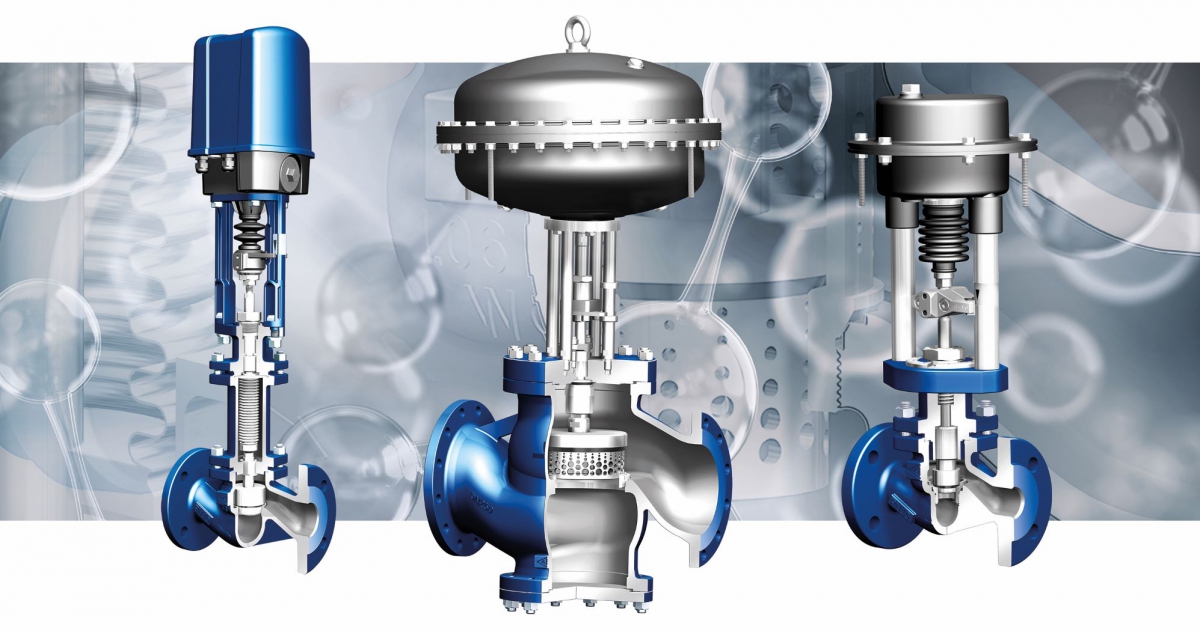

ARI-STEVI

Control valves - Reliable even under critical conditions. DN 15-500 / ½”-8” / PN 16-160 / Class 150-600 / -60 °C to +450 °C

• Precise and high performing: optimised flow characteristic

SUMMARY

ARI-Armaturen offers a large part of the required valves for water electrolysis plants - all from a single source and “Made in Germany”. As a leading international developer, manufacturer and distributor of quality valves, ARI-Armaturen has many years’ experience in advising and providing customised solutions in a wide range of applications along the entire hydrogen value chain.

Tel No: 01684 275752

Email: marketing@ari-armaturen.co.uk

Website: www.ari-armaturen.com

| Telephone: | 01684 275752 |

| Email: | inquiries@ari-armaturen.co.uk |

| Website: | http://www.ari-armaturen.com/ |

| More information on the ARI-Armaturen UK Ltd BVAA Member Directory Page |

Search related articles: ARI-Armaturen UK LtdIssue 79Hydrogen