Industrial Valve Summit: Conference Themes 2022

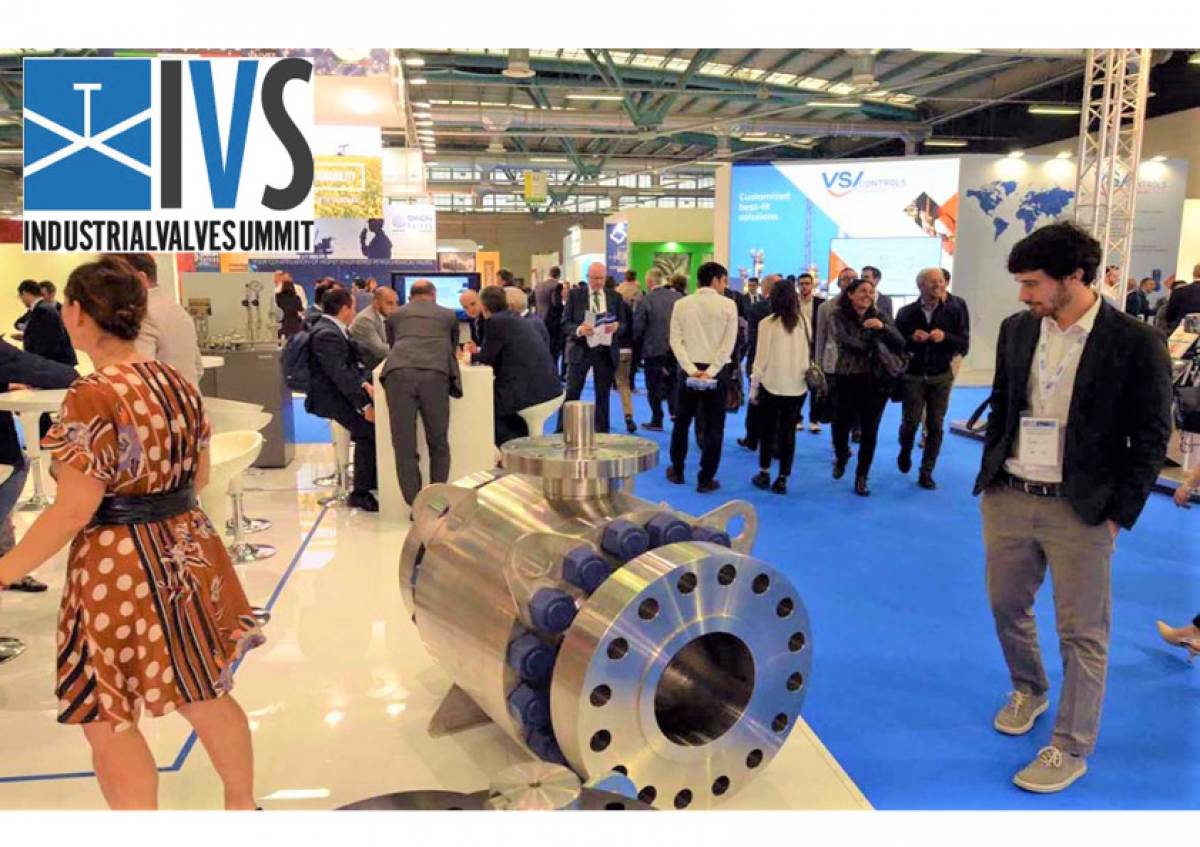

Photo: Industrial Valve Summit

Theme 1: Advances in safe valve design, materials, manufacturing, coatings and focus on additive manufacturing

This theme will cover new perspectives and developments in on-off / control valves’ and safety devices. This includes design materials, castings and forgings, manufacturing processes, coatings and corrosion protection technologies.

Contributions and case studies on fire testing and valve applications on hydrogen production development will also be appreciated. A specific focus will also be included to cover case-studies and developments foreseen in the valve industry, thanks to the use of metallic parts additive manufacturing (AM) or 3D printing technologies, with relevant materials’ and final products’ certifications.

Theme 2: Valve actuation and control

The impact of digitalization in plant design and management, particularly in the O&G sector, is improving the implementation of “smart” technologies, amplified by the intense and increasing use of reliable field devices and safe communication networks, in support of predictive maintenance and process optimization.

Valve actuation and control technologies are the main drivers and Authors are invited to bring their contributions and expectations.

Theme 3: Fugitive emissions and valve sealing technologies

Valve designers and plant operators have excellent reasons to minimize fugitive emissions in their facilities, by reducing the amount of process fluid released into the atmosphere and surrounding environment. Papers should cover today’s monitoring technologies, stem sealing techniques, packing designs and other advances in optimizing valve sealing performance, with reference to applicable national codes and international standards for tests and inspections.

Theme 4: Innovation, emerging technologies, and future scenarios

Technological development is perhaps the most fundamental and influential driving force of the 21st century, even though it is often difficult to predict timing, pace, and impact. Due to the Global Warming the demand for H2 and LH2 will rapidly increase. In different parts of the world they are being built or planned many H2 and LH2 production plants also using existing technologies and the large experience of the LNG industry. An in-depth study is needed to understand the impact on the fitting components and in particular on the Industrial Valves required by the H2 plants. These new technologies will create new opportunities and businesses, as well as new ways to handle existing challenges: the entire Valve Industry and its stake-holders are ready for this stimulating task.

Theme 5: International standards, supply specifications, lean documentation Management and remote inspection technologies

Large-scale projects, with complex international supply chains, rely on vendors and suppliers all over the world, with proper common and widely used Standards, Supply Specifications and Documents’ review cycle, fully endorsed and accepted by End Users and EPCs.

Comparison between existing international standards and current developments of commonly adopted specifications (e.g. IOGP-JIP33), strongly required by End Users and EPCs, will also find a proper space for open discussions and presentations. Lean documentation management will be one of the key elements for success.

An additional area will be dedicated to new forms of factory tests, including reliable real-time data transmission (audio, video, documents and images) with visual co-witnessed or customer remote operated assessments and inspections, which will reduce drastically wait-times, traveling costs and will maintain business continuity, thanks to the new use of Remote Video Inspections.

For more information, visit: https://industrialvalvesummit.com/

| Telephone: | 01295 221270 |

| Email: | enquiry@bvaa.org.uk |

| Website: | www.bvaa.org.uk |

| More information on the British Valve and Actuator Association BVAA Member Directory Page |

Search related articles: British Valve and Actuator AssociationIssue 67Industry Events