Adding Value to the Motor Operated Valve: Part 3

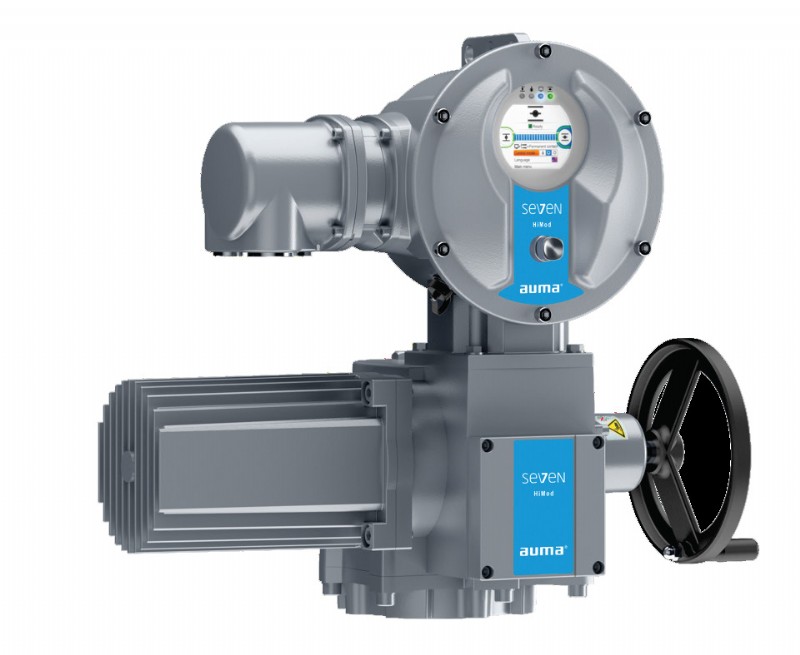

AUMA’s SIPOS SEVEN actuators feature animated colour screens for ease of operation and attract substantial Capital Allowances for their energy efficiency.

AUMA Actuator controllers situated in an easily accessible walkway, separate from the drive units

AUMA drive units can be up to 100m away, and may be in difficult, confined or hazardous areas.

AUMA’s ability to mount controls separately from the motor and gearbox allows flexibility in installation to avoid confined space or hazardous area working

The valve control market faces increasing pressure from commoditisation of its products. Here’s how to avoid a race to the bottom.

In the third of four Masterclass articles we continue to look at how AUMA Actuators Ltd addresses the challenges of commoditisation in valve applications. The series shows how modern electric actuators create value as they are specified, installed, used and maintained. Each article focuses on a different stage of the product’s life cycle:• Control system design and actuator specification

• Plant installation and commissioning

• Plant operation

• Maintenance and asset management. Together, the four articles consider how an integrated control and actuator solution better satisfies customer needs and adds real customer value.

Design, specification, installation and commissioning

In the first article [Valve User, Winter 2015] we saw how the powerful control features of modern actuators bring benefits at the design stage. For example, analogue-todigital [A/D] converters built into AUMA actuators simplify control system design by avoiding the need for flow and level sensors to have their own fieldbus A/D converters. Variable-speed operation as found in the SIPOS actuator series can eliminate water hammer, reduce valve seat wear, improve emergency shutdown performance, and provide near-linear performance from lower-cost non-linear valves.

The second article [Valve User, Spring 2016] showed how actuator design features affect the ordering, installation and commissioning phases of a project. AUMA’s modular actuator concept allows the three key components to remain separate right up to installation. Wiring, programming and commissioning can overlap, saving many weeks on tight project timescales. On-site cabling becomes a plug-and-play operation. Modular assembly keeps other site work to a minimum, saving time and improving safety especially when working in confined spaces or at heights.

In this third article we move on to show how choosing the right actuator can benefit dayto- day plant operation in terms of energy efficiency, ergonomics and controllability.

Energy efficiency

Large actuators and those that operate frequently can be high energy users, and multiple actuators on large sites are often second only to the pumps on site in energy demand. The SIPOS SEVEN variable speed actuator from AUMA features an innovative 3-phase inverter drive that significantly reduces energy consumption. A drive operating at a lower speed consumes a significantly lower amount of power. SIPOS SEVEN can be soft-started so there is no high start-up current, and adjustment of speed throughout each cycle means that, as well as potentially damaging effects such as water hammer being avoided, the actuator only drives at full speed for a short time. SIPOS SEVEN is the only actuator on the Energy Technology List (ETL), which is regulated by the UK Government through the Carbon Trust. It qualifies for Enhanced Capital Allowance, which provides 100% tax relief, currently at 20%, in the first year for product purchase, installation and transportation. A generous contribution from the tax man and a substantial discount for the capital investment.

Ergonomics

Site engineers don’t want equipment that is complicated to work with and counterintuitive to set up. They don’t have the time and space to carry a full set of instruction manuals for every piece of site equipment or device-specific handheld tools that can be easily misplaced, and manufacturers can lose support very quickly if, on a rainy sewage treatment works in the middle of the night, an operator can’t work out how to remedy a simple problem. AUMA has approached this issue with a simple and straightforward sequencing of commands, easily accessed from a clear and well laid out control interface. The modular approach also supports maintenance through simple parts exchange and offers future upgrade opportunities in a similar way.

The SIPOS SEVEN actuator has a large, clear colour LCD screen providing easy access to all functions that can be configured for viewing from any angle. Control sequences are easy to follow, with animations showing key actions. AUMA is a global brand, and multilingual support is built right in. Once the process is set perfectly, the sequence can be easily downloaded and cloned to other actuators working on similar valves to minimise set up time.

Health and Safety

Modularity is a concept at the heart of the AUMA range, and can enhance health and safety and improve site efficiency. Valves and actuators are heavy, and by mounting and moving the components separately the need for a sling or additional manpower can be avoided. AUMA actuator controls can be mounted separately from the motor and gearbox, connected by an umbilical, which means that a single operator can attend to them, even if the actuators themselves are mounted in a hazardous or confined area.

Controllability

We have mentioned in previous articles how the modularity concept helps in reducing project lead time. By sending the field wiring loom and any umbilical cords to the electrical sub-contractor, and MOV controls to the C&I subcontractor, many days on site can be taken out of the project.

A further way that value can be added to the actuator installation is by the minimising of cabling within the data network. Why connect a level sensor, for example, to a separate Profibus circuit, when it can be connected directly to an AUMA actuator for data transmission. This approach results in significant savings in installation time, in cabling and in hardware.

This third article has shown how choosing the right actuator can benefit day-today plant operation in terms of energy efficiency, ergonomics and controllability. In the next one we will turn to maintenance and asset management, including training standards.

Tel: +44 (0)1275 871 141

Email: mail@auma.co.uk

Web: www.auma.com

| Telephone: | 01275 871141 |

| Email: | mail.uk@auma.co.uk |

| Website: | www.auma.co.uk |

| More information on the AUMA Actuators Ltd BVAA Member Directory Page |

Search related articles: AUMA Actuators LtdIssue 38ActuatorsElectric ActuatorsElectro-Hydraulic ActuatorsRemote Control SystemsGearboxesControllersSwitchboxesGas-over-oil ActuatorsValve AutomationMaster ClassPneumatic ActuatorsActuator TestingMounting KitsManual ActuatorsFire ProtectionHydraulic ActuatorsCompact ActuatorsRotary Actuators