Why choose Coriolis?

Commercial Coriolis flowmeters are a relatively recent innovation, having emerged in the mid-to-late 1970s. Steady technical improvements since then have greatly increased their accuracy and acceptance in the process industries. Today, direct mass flow measurements account for up to 20 percent of worldwide flowmeter applications.

How they work

A Coriolis flowmeter requires a force acting on a tube carrying a flowing fluid. This force actually deforms tubes through which the fluid flows. The amount of deformation depends directly on the mass flow rate through the tubes. Signals from sensors measuring this deformation provide a direct indication of the mass flow rate.

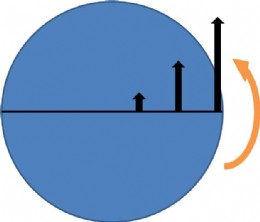

In Coriolis flowmeters the concept of angular momentum comes into play. Angular momentum is a function of the point’s radius from the axis, the mass at the point, and its speed. The further the mass from the axis, the faster its rotational speed and the greater its angular momentum.

This is demonstrated in the diagram below, which shows a counter clockwise rotating carousel viewed from above. The length of the arrows indicates the relative magnitudes of velocities of the points on the diameter.

| Telephone: | 01480 4753221 |

| Email: | info@gb.abb.com |

| Website: | www.abb.co.uk/measurement |

| More information on the ABB Limited BVAA Member Directory Page |

Search related valve / actuator articles: ABB LimitedIssue 30Flow Meters

-web.jpg)