ParCoat® Coatings from Parker Prädifa for smooth and reliable installation of seals

The seal, materials and coating specialist delivers important value-added with powerful coatings specifically developed for elastomeric products

During assembly processes, there is a risk of seals that look near-identical but have different functions being mixed up. Another risk is that of seals being damaged during installation due to high assembly forces. Typically going undetected initially, both of these potential error sources may lead to premature failure of the entire sealing system with respective consequential errors and costs.

In addition, high-volume manufacturing of elastomer seals supplied as bulk material that is separated in conveyor systems entails the risk of seals sticking together. The resulting stacking of sealing elements may lead to in-process trouble up to and including line standstill.

Easy and Reliable Installation Due to Systematic Modification of Surface Properties

With ParCoat® coatings the surface properties of elastomeric components can be systematically modified and optimized. They are suitable for all commonly used elastomer grades and clearly reduce assembly forces, among other things. For instance, with standard connectors on automotive air conditioning systems, a reduction by 50% and more can be achieved compared to uncoated O-rings or O-rings with other coatings.

Clean separation, depositing and feeding in high-volume production is ensured by choosing a respective ParCoat® coating as well.

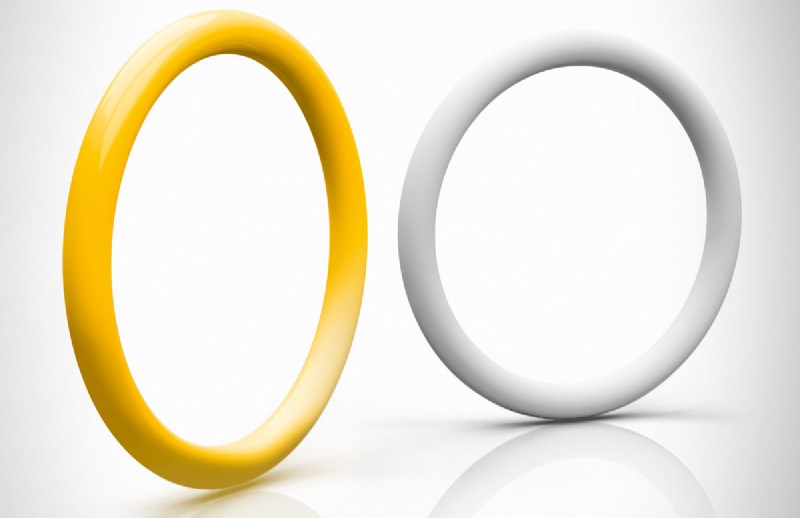

Color Coding Prevents Mix-ups

Various coatings in colored and transparent versions are available, depending on the application requirements. Colored versions serve to mark products and to avoid mix-ups. In addition, for corporate identity purposes, elastomer seals may be coated in the customer’s corporate color.

Especially for small or special production series, for which the development of a respectively colored material is not economically feasible, ParCoat® coatings are an easy and cost-effective way to provide elastomeric components with the desired color. On the other hand, transparent versions are used to coat colored basic compounds when the basic color must not be altered.

Tel: .+49 (0) 7142-351-0

Email: praedifa@parker.com

Web: www.parker.com/praedifa

| Telephone: | 01271 313131 |

| Email: | ipd@parker.com |

| Website: | www.ipde-innovations.com |

| More information on the Parker Hannifin Manufacturing Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Parker Hannifin Manufacturing LtdIssue 50Related ProductsSeals

-web.jpg)