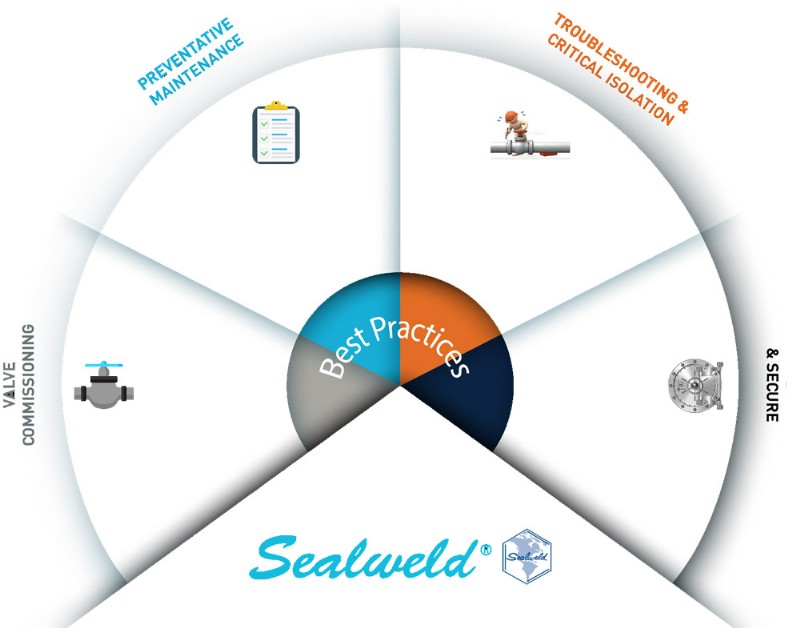

Best practices for Ball, Gate and Plug Valve, life cycle maintenance

Unfortunately this is typical of some installations and subsequently many valves will fail when called upon.

This article will outline the recommended practices to ensure continued performance of your ball, gate and plug valves.

Sealweld has manufactured a range of Valve Care Products since 1969, is recommended by many of the world's largest valve manufacturers, and are specified as "no substitute" by many of the worlds largest pipeline operators and oil and gas companies.

For over fifty years, professional valve maintenance technicians around the world have come to depend on Sealwelds consistent quality and performance both in routine use and in emergency situations when a critical isolation is demanded.

Sealweld products and procedures have been proven to resolve over 80% of most common valve problems in natural gas, crude oil and related hydrocarbon product services.

Sealweld Product Summary

Odyssey Solvent Removes heavy deposits of grease, lubricant, sludge and dirt from internal valve passages and metal parts.

Valve Cleaner Plus Deep cleans valves critical seal faces and internal sealant passages.

Weld Shield A product applied manually to weld-in valves designed to disperse heat and reduce damage to soft elastomer seals during the welding process.

Equa-Lube Eighty Light lubricant, ideal for new commissioning and maintenance on valves with little or no wear

#7030 Blends Lubricant/Sealant ideal for use in frequently operated valves known to have minor to moderate seat leakage. Available in Arctic, Winter and Summer grades

Total Lube #911 Viscous lubricant / sealant for worn valves with moderate leakage problems.

#5050 Sealant A higher grade, non-hardening valve sealant proven to seal scratches up to 0.030, in grades Standard to XXXH.

Winter-Seal #2525 Cold climate alternative to #5050.

Eterna-lube 1000 An anti-seize compound and high temperature lubricant for severe service applications.

Steam Shield 2000 Speciality lubricant tested and proven to remain stable at high temperatures.

Pack King #301 Mouldable stem packing that forms a durable yet replaceable seal.

Stem Packing Sealweld offers a range of stem packing suitable for all applications

Manual & Pneumatic operated injection equipment.

Flow Wolf Sealant injection fittings, inner checks, and adaptors for Ball, Gate & Plug valves.

Sealweld Valve Care Products are exclusively available from Enermech divisions around the globe at www.enermech.com. sales@enermech.com +44 (0)1224 723300

Tel: 01224 723 300

Email: sales@enermech.com

Web: www.enermech.com

| Telephone: | 01224 723300 |

| Email: | sales@enermech.com |

| Website: | www.enermech.com |

| More information on the EnerMech Ltd BVAA Member Directory Page |

Search related valve / actuator articles: EnerMech LtdIssue 52Valve Repair and Service

-web.jpg)