Westlock Controls - at the forefront of innovation

Over 20 years ago, Westlock pioneered the use of Hall Effect sensing for contactless tracking of valve position. Since then, valve positioner and transmitter manufacturers globally have adopted this technology. However, Hall Effect sensor has its limitations with no Beacon indicator or end-of-stroke sensors within same enclosure as there are no moving connections between the device and the valve. We have solved this problem by integrating TMR non-contact sensing technology on a mechanical shaft that fits a Beacon indicator and end-of-stroke switches without compromising our million-cycle high accuracy and reliability promise.

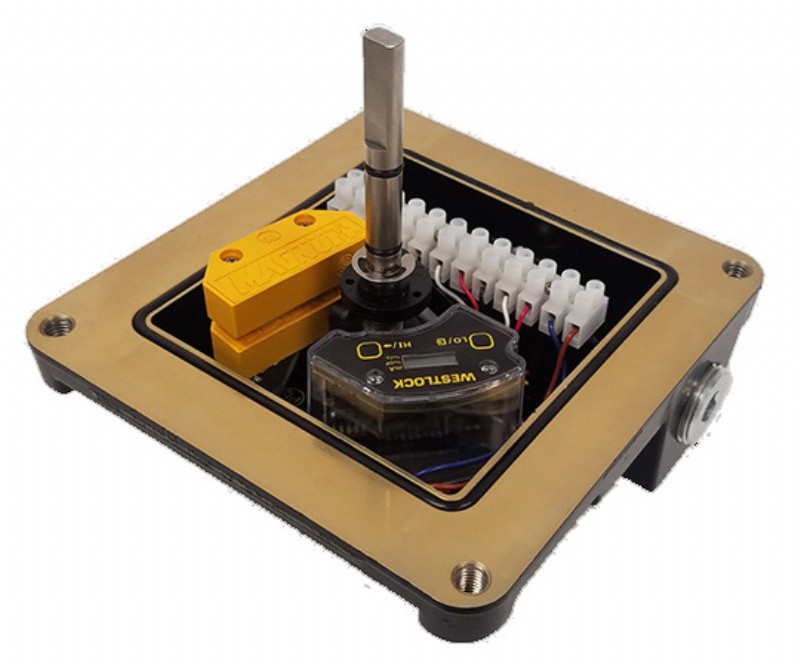

Westlock’s Digital EPIC D200 has it all – global hazardous location approvals, 4-20 mA transmission over HART®7, quick and intuitive one-touch calibration, Beacon indicator, and optional end-of-stroke switches! (Yes, even our very own hermetically sealed MAGNUM proximity switch!) Nevertheless, we have taken it a step further. You can enhance D200 with our advanced Falcon V solenoid valves. Designed and manufactured in the USA by Versa, Falcon V solenoid valves are engineered with precision to be integrated with our transmitters. Rest assured, our Digital EPIC D200 is a smart choice to operate your plant at maximum efficiency.

Digital EPIC D200 combines the advantages of 4-20 position transmission with end-of-stoke switches offering redundant feedback in critical valve applications. A typical process plant has thousands of mechanical or proximity valve monitoring switches in operation. With the advent of universal I/O (points are programmable to DI/DO or AI/AO), connection for transmitter is same as a traditional switchbox.

A signal transmitter can replace each pair of switches thus, freeing up thousands of I/O connections for future plant expansions. D200 saves up to 80% upfront cost due to less number of wires and termination, less marshalling space, quick calibration and commissioning, less HMI/DCS tags and DCS configuration, and overall installation time. Costs to maintain valves and rotary equipment can take up a large chunk of a plant’s maintenance budget.

Digital EPIC D200 not only provides more data on critical valves via HART®7 than a traditional switchbox but also, saves significant life cycle costs over it.

Westlock’s Digital EPIC D200 is a next generation position transmitter that incorporates advantages of TMR non-contact sensing, 4-20mA HART®7 communication, highly visible Beacon indicator, and end-of-travel redundant switches to provide crucial data on your critical valves and peace of mind to you. To learn more, visit us at www.westlockcontrols.com.

Tel: 01892 516 277

Email: sales.emea@westlockcontrols.com

Web: www.westlockcontrols.com

| Telephone: | 01892 516277 |

| Email: | sales.emea@westlockcontrols.com |

| Website: | www.westlockcontrols.com |

| More information on the Westlock Controls Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Westlock Controls LtdIssue 53Transmitters

-web.jpg)