DP Flow: The latest version of the engineering software tool CONVAL® has been released

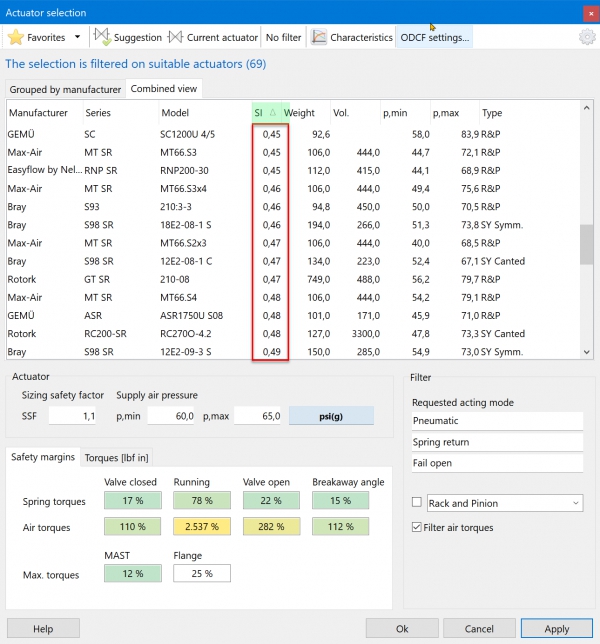

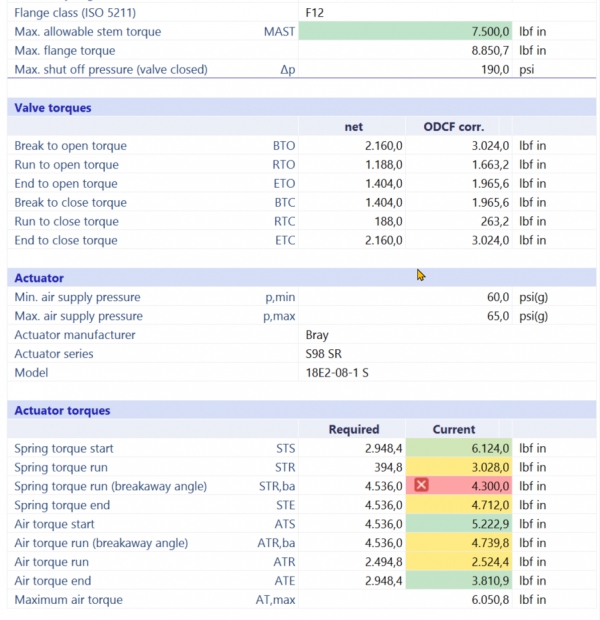

The latest version of the engineering software tool CONVAL® has just been released, which, after more than 30 years on the market, is now available as Release 11 for Windows. CONVAL® has always supported the manufacturer-independent design of valves. Whereas in the beginning it was only control valves, the current version also covers, for example, on/off valves along with the selection of suitable actuators, safety valves or steam-converting valves.

ANDREAS VOGT - F.I.R.S.T. SOCIETY FOR TECHNICAL AND SCIENTIFIC SOFTWARE APPLICATIONS MBH

Depending on the environment in which one operates, dealing with the topic - perhaps the sizing of a valve or the selection of a suitable actuator - is often limited to the individual component taken out of context.

For the sales engineer of a valve company, this is common practice. He limits himself only to the device to be sold, from the narrow range of products and applications available to him. Therefore, very specialised tools, often less technical than sales-oriented are often used here but they are sufficient for the purpose at first sight.

As a rule, these tools are manufacturer-specific and partly work with proprietary methods, even though there may be a corresponding standard/norm for a task. Sound prediction for valves is a good example here. The range and history of standardised procedures is already large, that of proprietary, sparsely documented methods perhaps even larger. This drastically limits the validity of the predictions, especially for a product comparison.

A Valve Integration Centre has different requirements as a much broader spectrum of devices has to be considered. If you are involved in plant planning, operation or maintenance, the whole thing looks different. The spectrum of components and their manufacturers, as well as the context in which they are operated, is enormous.

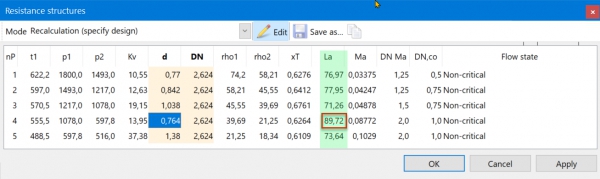

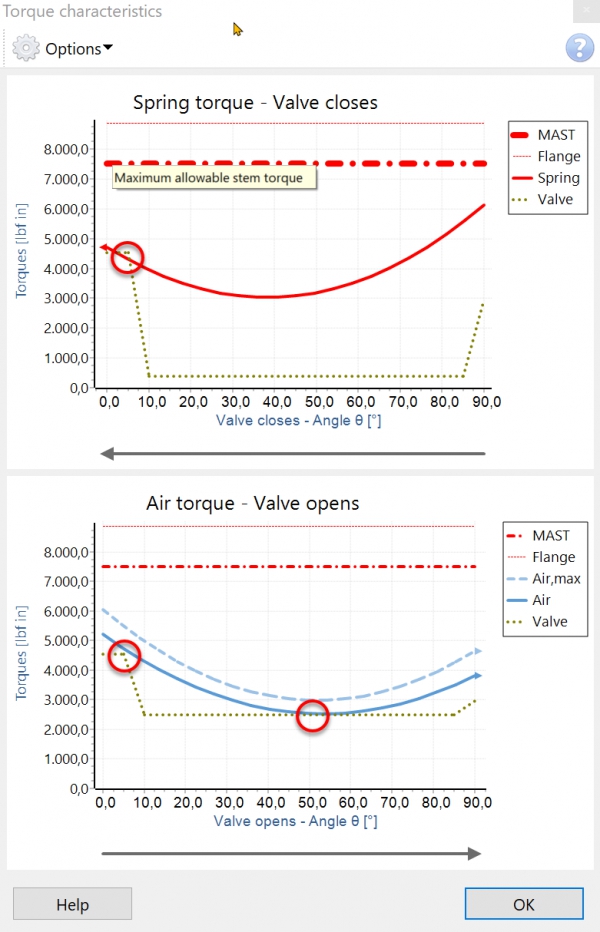

The goals pursued are also different with safety, long-term reliability, energy efficiency and low maintenance etc. clearly in the foreground as often it is no longer a question of procuring new valves or actuators. Process plants and their process parameters take on a life of their own. This regularly pushes installed components to their limits or even beyond. For example, in the case of a revamp, a capacity expansion or even just a different mode of operation, due to the associated changes in the process data. The focus here is on anticipating potential problems and evaluating possible solutions.

Manufacturer-specific/proprietary tools quickly reach their limits for many reasons. Not only because they do not cover all the devices that occur, but also because they are simply not designed to predict the effects of changing process data on these components, let alone to calculate the process data correctly in the first place.

Pure valve or actuator design tools are not sufficient here. Starting with the calculation of process data such as media properties (density, viscosity, boiling pressure) up to the thermodynamic simulation or change of process data by the valve (temperature change, flashing, sound velocities), further tools must be in the toolbox here.

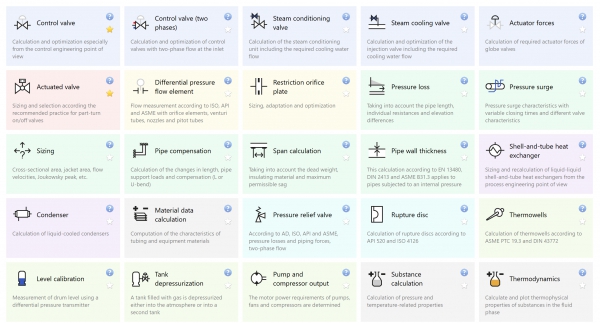

Figure 1 shows an overview of the most important main modules of CONVAL®, and it quickly becomes clear that this is not only about valves of all kinds, but also about the adjacent areas and components.

Read More...

Software-supported design and optimisation of common valve applications and more (dp-flow.co.uk)

If you require further information on this product or would like a quotation, please contact dp-flow on:

Email: sales@dp-flow.co.uk

Telephone: +44 (0)1865 600245

| Telephone: | 01608 544222 |

| Email: | sales@dp-flow.co.uk |

| Website: | https://www.dp-flow.co.uk/ |

| More information on the DP Flow Ltd BVAA Member Directory Page |

Search related valve / actuator articles: DP Flow LtdIssue 63Miscellaneous

-web.jpg)