Rotork Actuators with thrust compensators

Assuring reliable operation of high temperature chemical valves

Rotork IQPro valve actuators with thrust compensatorsinstalled on the new Mitsui Chemicals plant.

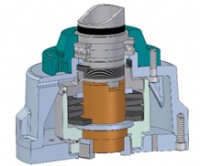

Cutaway diagram of the thrust compensator, showing how the stem nut is supported on springs to allow expansion and contraction in response to thermal changes without altering the valve position.

The new plant, which is being installed by Mitsui Chemicals Inc. at Ichihara, uses Mitsui’s proprietary technologies to manufacture specialised chemical products. During the process the gate valves operated by the Rotork actuators will be handling gases at temperatures between 300°C and 650°C.

In such severe operating environments there is a potential danger that a closed valve could become jammed in its seat as a result of the thermal expansion of its valve stem. In extreme cases this can cause the valve stem to distort or the valve to break. Conversely, a valve that is moved to its closed position when at a very high temperature can be prone to seat leakage if it subsequently cools down.

In order to overcome these potential problems on eighteen of the valves, Mitsui Chemicals accepted the valve vendor’s recommendation to use Rotork IQPro actuators equipped with a specially modified valve stem nut design. The design - known as the thrust compensator - was originally developed to overcome critical high temperature applications in the nuclear power generation industry. The thrust compensator consists of a spring loaded stem nut that will absorb any expansion or contraction caused by temperature fluctuations without affecting the position of the closed valve stem. The construction of the device is also designed to ensure that the positive valve shut-off demanded in critical applications is not compromised.

The Rotork thrust compensator design solution has proved itself in many severe service applications. As a result it is generally specified as standard for high temperature operation by the manufacturer of the gate valves supplied for the Mitsui Chemicals project.

Rotork Controls Ltd.

Tel: +44 1225 733200

Website: www.rotork.com

| Telephone: | 0113 256 7922 |

| Email: | mail@rotork.com |

| Website: | www.rotork.com |

| More information on the Rotork UK BVAA Member Directory Page |

Search related valve / actuator articles: Rotork UKIssue 12Electric Actuators

-web.jpg)