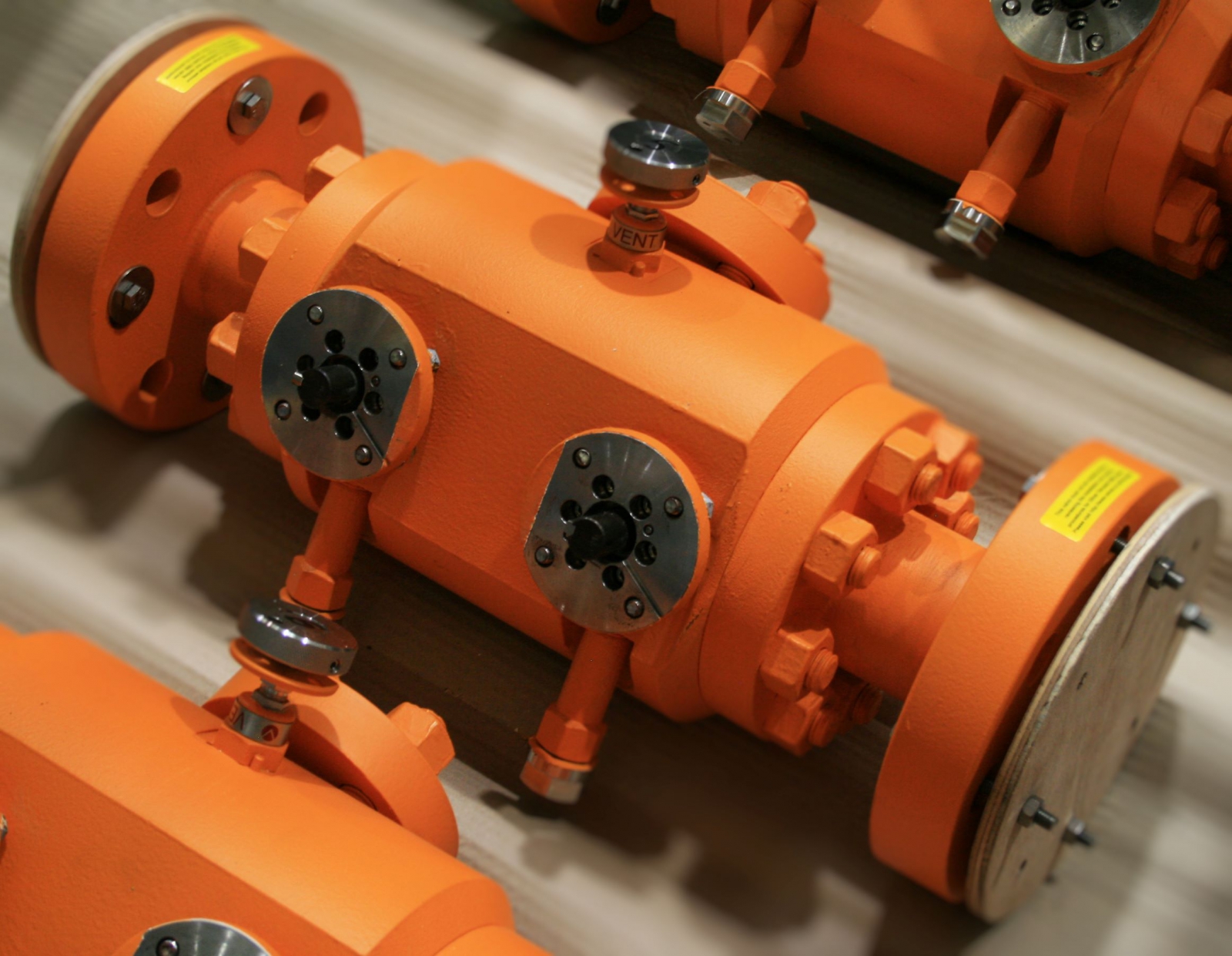

Oliver Twinsafe Valves of Many Colours

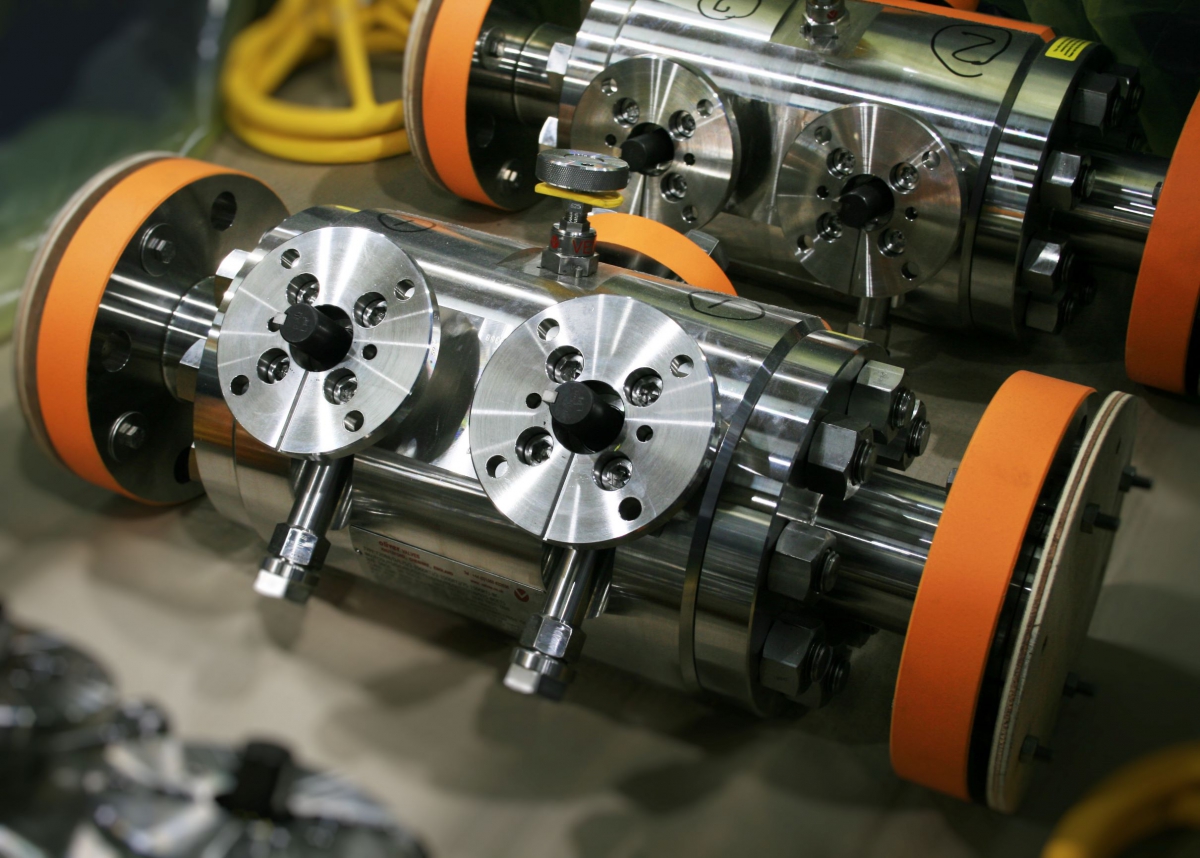

Oliver Twinsafe’s in-house paint shop has been busy applying the finishing paint to an order of several hundred double block and bleed valves that are bound for Saudi Arabia. The customer has requested to have a number of valves custom painted, either fully or partially, with identification markings across the casing and flange; a request that Twinsafe have become experts fulfilling.

The paint shop is fully equipped with the latest shot blast and spray paint booths, curing rooms, and has the capacity of hundreds of valves per day. A wide range of stove cured wet paint systems are available to choose from, they include: zinc rich epoxies, inorganic zinc silicates, epoxy mastics, high temperature silicone, epoxy phenolics, acrylics, and polyurethanes. Also offered are specialist painting techniques such as Thermally Sprayed Aluminium - this is an application of molten metal, usually aluminium, which gives a very high corrosion resistance for use at very high operating temperatures. NACE inspection is available on request and supplied with full paint certification and reports.

To get a high standard paint finish, the valves complete a thorough process, that include, degreasing and masking the valve to prevent ingress of shot in the bore, shot blasting, priming, intermediate coats applied, and then finished with a topcoat in your chosen RAL or BS colours. Identification markings painted on the valve are always an option too and these can be fully customised to include application of a multi-layer painting process to conform to your own specification.

For your next custom painted valves, contact Oliver Twinsafe Valve:

|

Tel No: |

+44 (0) 1565 632 636 |

|

Email: |

|

|

Website: |

|

|

LinkedIn: |

| Telephone: | 01565 632636 |

| Email: | sales@valves.co.uk |

| Website: | www.valves.co.uk |

| More information on the Oliver Valves Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Oliver Valves LtdIssue 77ValvesDouble Block and Bleed Valves

-web.jpg)