BVAA - Meet the Trainer

Adrian Croft – New Control Valves Lecturer

Adrian Croft, Control Valve Consultant and Lecturer

Adrian has recently joined our highly experienced team of BVAA trainers and brings with him a wealth of knowledge. He has further developed and enhanced the materials for the Control Valves Training, demonstrating our commitment to excellence, as we consistently strive to meet, and exceed, our learners’ expectations.

About Adrian Croft

Adrian has worked in the control valve industry since 1977 when he started his apprenticeship at Blakeborough Valves in Brighouse, which later became part of the Weir Group, now Trillium. Whilst at Blakeborough he was involved in most aspects of control valves, from design, specification, onsite support and providing applications solutions. In 2002 he moved to Kent Introl where he was responsible for providing control valve applications solutions. Adrian moved back to Weir in 2004 as Control Valve Product Manager in a more sales orientated role which often involved giving technical presentations to customers and end users and visiting sites to investigate problem valves. He now works as a Specialist Valve Engineer and Lecturer.

Control Valves Training (CPD Certified)

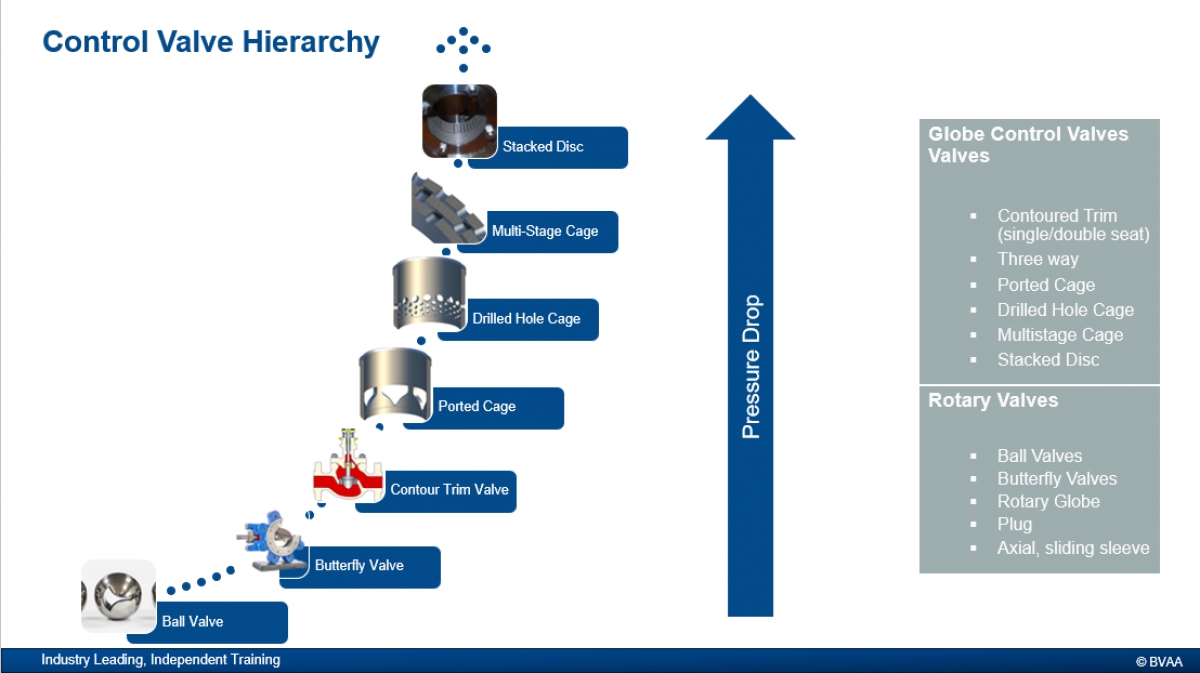

Arguably control valves are the most technically complicated valves in today’s market. They are subject to extremes of pressure, pressure drops and temperatures, yet still must be able to perform without any interruption to the process. More and more technically challenging applications require valves that will control for extended periods, therefore understanding both the application and the valve limitations is important.

Adrian says, “In the time I have worked in the control valve industry, valve specifications and requirements have changed beyond recognition. For example, back in the 1970’s it was unusual for a control valve to be greater than 8” in size, it was only towards the later 1970’s that 10” and 12” valves started to be required.

Equally, pressure ratings compared to today’s requirements were relatively low and although Class 900 and Class 1500 rated valves had been produced, they were more of the exception than the rule. It was very rare to get a requirement for a Class 2500 rated valve.”

Adrian explains that, broadly speaking, two big changes have occurred:

- The demand for control valves operating with higher pressure drops, which has largely been driven by the offshore industry.

- On power applications there has been a drive to control higher and higher temperatures, which is technically challenging both from a materials and a valve sealing point of view.

He goes on to say, “Across the valve industry we have seen a significant reduction in the knowledge base and overall, a lack of experience in specifying more technical applications. For everyone associated with both the valve application and the valve specification it is important to have a good grounding in the fundamental principles of control valves.”

Why choose BVAA Training?

The BVAA is not associated with any single valve company, and therefore the courses that we offer are un-biased and give a broad overview of control valves and how they can be applied.

Where there are specific requirements, for example related to offshore applications, then course can be tailored to suit, simply contact the BVAA to discuss your requirements.

Next Classroom-Based Training Course: 17th April 2024

Find out more and book your place today: https://www.bvaa.org.uk/training_course_details.asp?id=280

| Telephone: | 01295 221270 |

| Email: | enquiry@bvaa.org.uk |

| Website: | www.bvaa.org.uk |

| More information on the British Valve and Actuator Association BVAA Member Directory Page |

Search related valve / actuator articles: British Valve and Actuator AssociationIssue 90Training

-web.jpg)