Emerson Ball Valve Solutions Meet Stringent Fugitive Emissions Requirements

Over the past 20 years, more countries worldwide are increasing regulations related to controlling and reducing emissions.

Figure 3: Emerson offers a wide range of ball valve solutions, such as these floating ball valves, that meet the B standard or better for fugitive emissions.

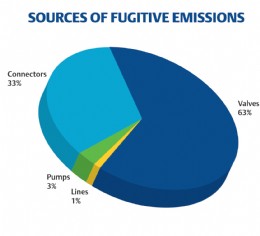

Figure 1: End users can help combat fugitive emissions by monitoring their valves, the No. 1 source of fugitive emissions according to the EPA.

Figure 2: In the last 20 years, international fugitive emissions standards and regulations have increased.

Fugitive emissions are unintentional emissions of gases or vapors from pressurized equipment due to leaks and other unintended or irregular releases of gases, mostly from contained industrial processes. Fugitive emissions do NOT come from the usual sources of pollution, such as chimneys, stacks, and vents. Instead, they are pollutants released into the environment due to leaks in equipment such as pipelines, seals, or valves. The reality is that valves are the number one source of fugitive emissions.

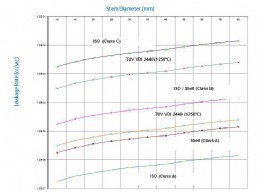

Monitoring and control of fugitive emissions is driven by national or international regulations or protocols, which in turn rely on standards or specifications. Two applicable laws currently specify the acceptable limits to the fugitive emissions, particularly for volatile organic compounds (VOCs) – the Clean Air Act, USA, EPA Procedure 21, and TA-Luft, Germany, VDI 2440. Well-known standards and specifications provide a path to compliance with these laws. These include ISO 15848-1 & 2; API 624; Shell MESC 77- 300/312 and TA Luft VDI 2440.

The two common ways to monitor a valve’s fugitive emissions are global measurement and local measurement. A combination of the two methods can also be used per some standards and/or enduser specifications. During prototype testing of valve designs the global method is preferred, where the intention is to capture all emissions and volume over time. On-site testing typically uses the local measurement or “sniffing” method, which measure the leakage rate at that point in time, as the global method is difficult to replicate.

Emerson’s FE-Compliant Solutions

Emerson’s fugitive emissions solutions, with resilient stem packings, meet the stringent ISO 15848-1 Class B standard or better, which means they exceed even the most stringent leakage standards allowed by the EPA and local “designated zone” (DZ) government regulations. Emerson’s engineering and technical team addressed these design considerations for its FE-compliant ball valves with:

• Live loaded packing for temperature variations

• Preventing packing rotation • Highly efficient stem sealing system

• Very smooth stem and stem bore surface finish

• Simultaneous contact between packing , stuffing box and the stem simultaneously

• Independent PTFE and graphite packings

Emerson’s KTM and Virgo series of ball valves have been proven to be effective low-emission solutions and are installed in a wide range of industrial customer facilities in every region of the world. Emerson ball valves have been designed for and have achieved FET (Fugitive emissions testing to ISO 15848-1) tightness Class A / B with endurance class CO1/2/3 for a wide temperature range, in accordance with customer requirements in valve pressure class 150 to 2500.

Additionally, the Emerson team has enhanced designs to work a solution within the current design platform, which has contained costs, while providing broad range industry solutions. End usersanctioned third party inspection agencies witness, approve and certify the entire cycle testing of these valves, assuring credibility of the results. Customers rely on these solutions with confidence when incorporated into a full LDAR program to meet regulatory compliance. Emerson ball valves reduce or eliminate fugitive emissions, reducing the lost product revenues, enhancing the LDAR plans and reducing risk of potential of regulatory fines and lost revenue due to fugitive emissions.

For more information on Emerson’s KTM ball valve solutions, please visit http://valves.emerson.com/en/brands/ktm.

Tel: 0870 240 1978

Email: uksales@emersonprocess.com

Web: www.emersonprocess.co.uk

| Telephone: | 0870 240 1978 |

| Email: | uksales@emerson.com |

| Website: | https://www.emerson.com/en-gb/automation/home |

| More information on the Emerson Process Management Ltd BVAA Member Directory Page |

Search related articles: Emerson Process Management LtdIssue 43Ball ValvesStandardsR&DFugitive Emissions