‘Severn builds Valves no-one else can!’

Severn’s Colin Findlay

Inward bound valves awaiting assessment and repair

Part of the Severn Unival design office

Possibly the cleanest ‘dirty room’ in the industry

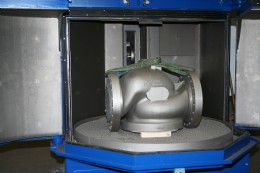

Part of the Severn Unival testing capability

And it’s not meant to be in the slightest way boastful. Just simply how Colin sees it. To illustrate the point he outlined to me the company’s latest example: a 36 inch, Class 900 fast-acting severe service control valve for a cryogenic application. How fast? Try just 2 seconds!

Two Key Differentials

Colin went on to explain why the company stands out from the crowd in the valve industry:-

1) ‘Although 90% of our business is Oil & Gas/ LNG, Severn Glocon’s root heritage is in the cryogenics industry – one of the valve industry’s most challenging sectors. With over 50 years’ experience we are widely accepted as the industry experts. Our fast-acting valve is just one example of that,’ he asserted.

2) ‘The Severn Unival business and its origins in “repair intelligence” make us unique in the industry.’

‘World Class Engineering Intelligence’

The above strapline is all over the brand new, hugely impressive Severn facility at Brighouse, so I asked Colin to explain the ‘intelligence’ references. He explained, ‘It’s very simple really. The Unival business is perceived as a valve repairer, but the Severn Glocon Group manufactures valves too. We don’t do – and never really have done – just “standard repairs.” ’

Colin continued, ‘Major project work, principally manufacturing of severe service control valves, is handled by our Severn Glocon business in Gloucester. “Established Plant” i.e. maintenance, repair and operations (MRO) work for major clients, is managed by Severn Unival here in Brighouse. But the two businesses work seamlessly together to ensure the very best technical support is given to the MRO teams, with an engineering review of applications, failures and proposed solutions looping back to the valve design and manufacturing teams.

Colin continued, ‘For decades we have taken severe service control valves, and painstakingly reviewed why they needed post-service repair and provided our clients and end-users - with whom we are extremely close - with a professionally considered opinion as to the causes and solutions.’

‘With the huge amount of data we have amassed we in effect have had a continuous product development based on live information. “World Class Engineering Intelligence” is therefore totally true,’ he beamed.

‘We design and manufacture high specification valves, develop and test them endlessly, and we supply them to clients all over the world with varied and challenging applications. We know precisely how the valves work and crucially how and why they can fail, and how to stop it happening again,’ Colin continued. ‘It puts us in a very privileged position but also means our clients know they can rely on us for the very best advice when it comes to repair, retro-fit, upgrade or replacement.’

Brighouse Facility

I asked Colin about the background to the impressive new facility overlooking Calderdale at Brighouse, known colloquially in the industry as ‘Valve Valley.’

‘Again very simple,’ he replied. ‘We’ve seen 360% growth in the last 5 years alone! The old Huddersfield site was too constraining at just 23,000 ft2 and we needed room to expand and improve our capabilities. The new 65,000 ft2 Brighouse facility is purpose built and at and we’ve spent over £2m fitting it out to our own specification. It gives us the space we needed for a rapidly growing business and a staff of 104. We need to attract and keep the best staff, to have the best facilities possible and to be super-efficient as a “Lean” business, so a brand new facility here was the answer.’

I jokingly asked if nearly triple the space was enough and was surprised to hear Colin’s reply of ‘Actually, “No.” We kept the Huddersfield site for storage – it’s still very much in use. We pride ourselves on very short lead times and the combined space facilitates that perfectly.’

‘The new site also gave us the opportunity to reorganise,’ Colin added. ‘The design offices and sales and support teams are separated but adjacent to one another. Their working environments are very different but when one needs to interact with the other they are just a couple of steps away. We also took the opportunity to include specially configured rooms for our respected Training function.’

I commented that the same philosophy appeared to have been extended to the shop floor. ‘That’s correct,’ Colin replied. ‘The new site allowed us to lay out the workshops in an entirely logical and efficient manner, from Goods Inwards right through all processes to despatch. We have isolated areas for inspection and assessment, machining, positive-pressure cleanrooms, ‘dirty rooms’, paint, assembly and test - even a submersible test tank.’

‘Last year we were awarded £½m grant from the Regional Development Fund,’ Colin continued. ‘One result of that is the brand new R&D facility you’ve seen here. Severn will be leveraging on its control valve technology and extending its penetration into the subsea market.’

‘We’re an independent, wholly UK-owned business and we’re also very keen on supporting the local economy,’ Colin added. ‘This area is synonymous with valve manufacture and wherever possible we aim to source locally, to ensure that continues. “Made in the UK” still means a great deal in the valve industry and we’re proud to put that on our products.’

There’s More

‘We also successfully incorporated “Leeds Valve” into the Brighouse site following its acquisition last year,’ adds Colin. ‘We’re already looking at development and an expansion of the butterfly range which should stimulate a lot of interest in the marketplace.’

‘The Severn Glocon Group doesn’t just include the two sites I’ve mentioned,’ he said. ‘As you know last summer we acquired LB Bentley in Stroud, Gloucestershire who specialise in the design and manufacture of small subsea valves for the global oil and gas market. This business has developed dramatically in the last year with tremendous growth and major customer qualifications and approvals. By merging their subsea expertise with the vast knowledge we already have across the Group we can expand our range of subsea valve types!’

‘We also started a new business, Severn Ball Valves, in Aberdeen in 2010 to cover the local market for traded valves, supplying balls valves obviously, but also gates, globes and check valves etc. too. This division now also has outlets in Perth Australia and Dubai. We supply the MARS product range as well, through dozens of UK distributors such as Ron Hague and ISIS.’ When I asked about how it’s doing, there’s just that warm, engaging smile again – business is obviously very good and growing substantially like the rest of the Group, who were awarded the “Queen’s Award for International Trade” in 2011.

‘Progress continues apace,’ concluded Colin. ‘For example we’ve just received a substantial valve management contract for the world’s third largest oil field. Every day there’s something new!’

Severn Glocon

Tel: +44 (0)845 223 2040

www.severnglocon.com

| Telephone: | 0845 6070 710 |

| Email: | sales@severnvalve.com |

| Website: | www.severnvalve.com |

| More information on the Severn Glocon UK Valves Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Severn Glocon UK Valves LtdIssue 26Company News

-web.jpg)