Heap & Partners - More than just another distributor

Figure 3 Heaps Extension tubes

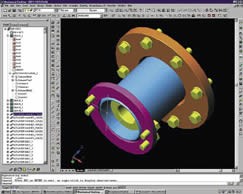

Figure 1 3D Solid modeling

Figure 2 Multi headed CNC machining centre

Figure 5 Heaps panels for nitrogen purging

Figure 6 American spec explosion proof panel

Heap & Partners have not only been in business longer than most (founded in 1866) they also have a long serving and uniquely experienced staff, having a combined experience of over 730 years in the valve market. Today they are investing heavily in all aspects of the business to ensure the service they offer is second to none.

Having their own Research & Development Department, in house Finite Element Analysis software, CAD/CAM as well as large stocks, enables Heap & Partners to offer a level of service way beyond distribution.

Design & Manufacturing

Using the latest release of Design Space enables the drawing office to quickly produce 3D prototypes. These feed automatically into the FEA software to ensure the design is fit for purpose and then the resulting code can be sent direct to the CNC machining centres. (Fig 2)

Bespoke Designs From Standard Components

Heap & Partners specialise in solving complex engineering problems for customers using standard components. Figure 3 and 4 show 14" Tomoe Tritec double block and bleed valves fitted with Heap & Partners torque tubes.

Figure 5 shows some examples of control panels designed to customer specification for nitrogen purging on an offshore rig. Figure 6 shows the inside of a panel designed and built to the American EXD standard UL Aexd.

Specialised Services

Heap & Partners offer a number of specialised services. Clean build valves prepared for hazardous duties such as Hydrogen Peroxide, chlorine and air (see figure 7. One of the largest flow test facilities in the country, capable of testing valve Cvís to an accuracy of 0.1%.

Heap & Partners are approved under PED legislation to modify the pressure envelope of the products they distribute. Hindle ball valves destined for Hydrogen peroxide need the throat boring out to improve the porosity. Saunders diaphragm valves can be modified for high vacuum, provided you have the in house skills.

Information Technology

Heap & Partners have been computerised since they first took delivery of a Phillips mainframe computer in 1970. Today they are still leading the way with a raft of IT projects including:

New quotation Software

Heaps Online Order Tracking Software (HOOTS)

Heaps Online Documentation System (HODS)

Heaps On Line Stock (HOLS)

KPI Dashboard

All linked to a mobile delivery system that will make key components of all 5 projects available to their sales engineers on their Blackberrys, all via a Blackberry friendly intranet site already set up and hosted from their central server room. By making critical data available to their sales engineers, via their Blackberrys, they ensure their people have real-time information to help their customers.

Conclusion

You donít get to be over 140 years old, by standing still. As David Millar, Managing Director points out "The average life expectancy of a UK company is 6 years. We treat every year as our first, so that we donít become complacent."

In the words of Albert Einstein "The only

source of knowledge is experience!"

| Telephone: | 0151 488 7222 |

| Email: | info@heaps.co.uk |

| Website: | www.heaps.co.uk |

| More information on the Heap & Partners Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Heap & Partners LtdIssue 6Distribution

-web.jpg)