Adding Value to the Motor Operated Valve: Part 2

Figure 1: AUMA’s modular actuator concept allows key components to remain separate right up to the installation phase – with significant savings in project time.

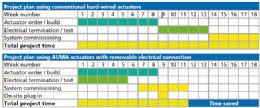

Figure 2: By allowing key phases to overlap, on-site modularity can cut weeks from the schedule.

Figure 3: An umbilical allows the control unit to be mounted up to 100 m away.

Figure 4: “Plug-and-play” components greatly reduce the amount of site work needed to install and commission motor operated valves.

In the second of four Masterclass articles we continue to look at how AUMA Actuators Ltd addresses the challenges of commoditisation in valve applications. The series aims to show how modern electric actuators create value as they are specified, installed, used and maintained. Each article focuses on a different stage of the product’s life cycle:

• Control system design and actuator specification

• Plant installation and commissioning

• Plant operation

• Maintenance and asset management.

Each stage involves different teams with diverse requirements. Together, the four articles consider how an integrated control and actuator solution better satisfies customer needs and adds real customer value.

Design and specification recap

In the first article (Valve User, winter 2015 p52) we saw how the powerful control features of modern actuators bring benefits at the design stage. For example, analogue-to-digital (A/D) converters built into AUMA actuators can simplify control system design by avoiding the need for flow and level sensors to have their own fieldbus A/D converters.

In addition, variable-speed operation as found in the SIPOS actuator series can eliminate water hammer, reduce valve seat wear, improve emergency shutdown performance, and provide near-linear performance from lower-cost non-linear valves. The built-in inverter for the drive motor can cut cabling costs without sacrificing torque, and even allow solarpowered operation in remote locations.

In this second article we move on to show how actuator design features affect the ordering, installation and commissioning phases.

Modularity saves critical weeks during the supply phase

Modular design of products is a popular way to cut costs, speed delivery and increase flexibility. AUMA takes modularity beyond the factory gates by allowing modules to remain separate right up to the installation stage. This can cut weeks from both the delivery schedule and the time needed for site work.

From the user’s point of view an AUMA actuator has three basic components: the electrical connector, which takes the form of a large plug and socket; the control unit; and the main body, incorporating the valve mounting, gearbox, motor and hand wheel (Figure 1).

On-site modularity allows each of these components to be routed to the appropriate subcontractor. The valve mounting, motor and gearbox can go straight to the valve supplier or pipework contractor as soon as they are ready, without waiting for the control specialists. The control unit can go to the control subcontractor, and the electrical connector to the electrical subcontractor. Allowing the wiring, programming and commissioning to overlap can save many weeks on tight project timescales (Figure 2).

Lower costs for power and data cabling

Although the main electrical connector is a relatively simple and low-cost component, it is key to the time savings shown in Figure 2. As well as power, the connector incorporates Profibus terminals as required. This means that the electrical contractor can install and test both power and control cabling in advance. As soon as the pre-commissioned control unit arrives on site, connecting it up is then a simple “plug-and-play” operation that does not even necessarily require an electrician.

In some cases, use of variable-speed actuators such as the SIPOS series can Figure 3: An umbilical allows the control unit to be mounted up to 100 m away. Figure 2: By allowing key phases to overlap, on-site modularity can cut weeks from the schedule. Figure 4: “Plug-and-play” components greatly reduce the amount of site work needed to install and commission motor operated valves. reduce the cost of power cabling and standby power supplies. With its built-in inverter drive, the SIPOS actuator develops full torque at low speed and without the high inrush currents typical of standard motors. As a result, cable diameters can be smaller.

Savings in data cabling, meanwhile, can result from the external I/O facilities built into AUMA actuators. With each actuator able to provide two 4–20 mA analogue and 4 digital inputs, 12 digital outputs and a 24V power supply, many field sensors can be connected to actuators rather than requiring their own Profibus cables, segment couplers and PLC I/O modules.

Installation and commissioning are quicker and safer

Modular design eases applications in confined spaces – and helps contractors work around any unforeseen problems – because each of the major components can be installed in any of four rotational positions, giving a total of 64 configurations (Figure 1). Where space is really tight or where harsh environmental conditions such as high levels of heat or vibration exist, a pre-wired umbilical cable allows the control unit to be positioned up to 100m from the valve (Figure 3).

The ability to test and pre-commission before the equipment arrives on site makes site work easier, quicker and safer. For instance, the motor operated valve can now arrive with the pipework, pretested and stroked, and with end stops and torque limits set. Cabling can be delivered as complete looms cut to length, assembled and tested.

As a result, final assembly and testing requires fewer contractors and less site work, including in potentially hazardous situations such as working at height or in confined spaces. Plugging in the electrical connector is a simple operation, and subsequent final commissioning is easier because shop-based pre-commissioning has largely eliminated the risk of errors appearing at the last minute (Figure 4).

In this second article we have seen how site modularity can cut weeks from the supply phase and simplify site work during installation. In the next one we will look at how choosing the right actuator can benefit day-to-day plant operation in terms of energy efficiency, ergonomics and controllability.

Tel: 01275 871 141

Email: mail@auma.co.uk

Web: www.auma.com

| Telephone: | 01275 871141 |

| Email: | mail.uk@auma.co.uk |

| Website: | www.auma.co.uk |

| More information on the AUMA Actuators Ltd BVAA Member Directory Page |

Search related valve / actuator articles: AUMA Actuators LtdIssue 36Master Class

-web.jpg)