Heavy-Duty Valves Undergo Safety, Seat Enhancements

WKM 370D6 trunnion-mounted ball valve sports safety, design, and test upgrades

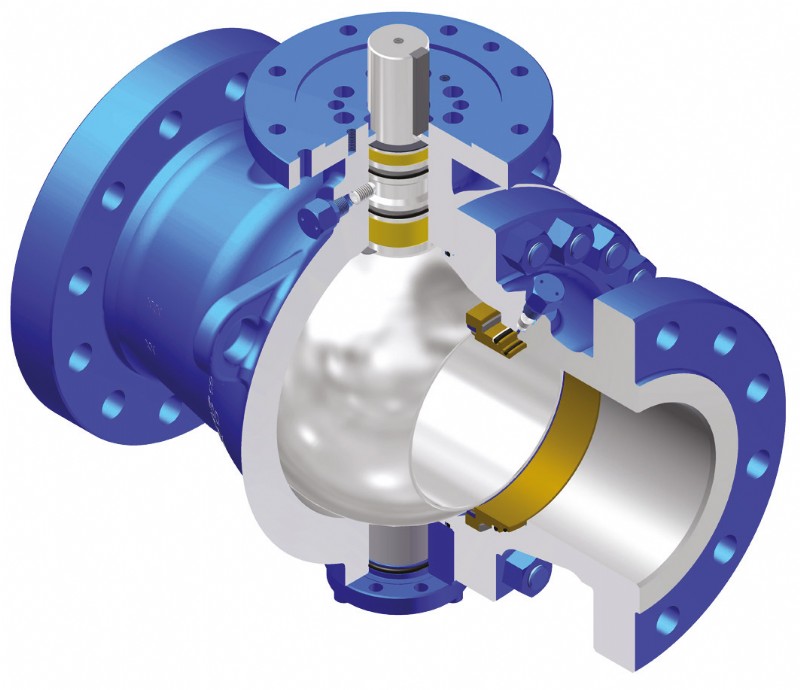

The WKM 370D6 trunnion-mounted ball valves are designed and engineering for heavy-duty performance in general purpose petroleum and chemical process applications. (Courtesy of Schlumberger)

Engineered for heavy-duty, reduced-maintenance performance and manufactured in a variety of body and seal materials, the D Series WKM* valves are commonly selected for many specialized applications such as gas distribution, gas transmission, oilfield production, and industrial applications.

The new WKM 370D6 trunnion-mounted ball valve has undergone safety and seat upgrades in response to operator requirements. The ball valve now features a new seat design that allows for better sealing across a range of material options like PTFE and PEEK, while lowering the torques required to operate the valves.

The WKM 370D6 valve is part of the Cameron, a Schlumberger company, broad portfolio of valves that includes gate valves, trunnion-mounted and floating ball valves, and resilient and metal seated butterfly valves. The new ball valves satisfy a wide range of ANSI and API 6D applications.

Built-in safety features

A full line of safety enhancements and features have been built into every WKM 370D6 valve. The entire size, pressure, and material trim range has been successfully certified to API 607 6th ed. Fire Test, giving operators confidence in valve performance in any situation. Safety Integrity Level (SIL) certification is available along with internally self-relieving seats, block and bleed capability in both the open or closed position, and explosive resistant O-rings in every valve.

Conformance with design and test standards

The D6 meets most major industry design standards. Designed, tested, and monogrammed to the latest edition of API 6D, every valve gets a full pressure test to ensure bubble-tight sealing. Testing also includes the low-pressure seat test as standard. Full B16.34 compliance is standard, both the wall thickness and valve bolting meet full B16.34 design requirements. All valves are API 608 and PED compliant, and can be ordered with a CE mark.

Preferred options available

Flexibility has also been designed into the streamlined WKM D6 trunnion valve, which features fewer components. Gear operators can be direct mounted on all sizes with no need for brackets or couplings. The operator can choose optional ISO 5211 top works and mounting with a simple adapter plate change. The operator can also choose full material options for NACE MR0175/ISO 15156 compatibility including 316SS ball, stem, and seats for all sizes CL 150 through CL 2500. Duplex, Inconel, 410SS, 4130 material options are also available. Full stainless steel and -50F lowtemperature construction are available. Valves can be ordered with 3-mil electroless nickel plating (ENP) internals for more corrosive applications, but at a lower cost than stainless steel. Operators can choose from a full range of coatings.

Environmental compliance

The WKM D6 has been designed and tested to meet ISO 15848 and API 641 for fugitive emissions compliance. Valve support

Services support is available, quickly and efficiently, with unmatched OEM expertise. Highly skilled engineers and technicians are available around the clock, seven days a week to support customer queries, troubleshoot problems and offer reliable solutions. To learn more, visit www.cameron.slb.com/wkmd6. *Mark of Schlumberger

Tel: +44 (0) 1638 665 000

Email: vminquiries@cameron.slb.com

Web: www.cameron.slb.com/wkmd6

| Telephone: | 01224 982000 |

| Email: | SMowatt@slb.com |

| Website: | www.products.slb.com/valves |

| More information on the Cameron, a Schlumberger Company BVAA Member Directory Page |

Search related valve / actuator articles: Cameron, a Schlumberger CompanyIssue 42ValvesBall Valves

-web.jpg)