SAFI - No Application Challenge Too Severe!

‘Even in the most challenging applications, Safi Valves can be called upon to provide solutions that other valve-types simply cannot manage.’

The application in question relates to phosphoric acid plants - which are hugely challenging in themselves - but all the more so when located in the sweltering temperatures of North Africa and the Middle East, and processing some pretty horrendous, abrasive media.

Steve continued, ‘Phosphoric acid is a mineral inorganic acid with the chemical formula H3PO4. A chemical reagent, it has a wide variety of uses, including a rust inhibitor, food additive, dental, orthopaedic and industrial etchant, electrolyte, flux and dispersing agent to name but a few. It is also a component of home cleaning products, but it’s most widespread use is probably in the manufacture of phosphates for fertilizers.’

Phosphoric acid is produced in three main commercial methods, ‘wet process’ being by far the most common. In the process, phosphoric acid is produced by reacting high concentrations of sulphuric acid with phosphate rock acid, and this also produces calcium sulphate (gypsum) and a range of other insoluble impurities. The addition of water and filtration removes the gypsum and other insoluble materials like silica. Fluoride is removed by evaporation, which also concentrates the solution, and various grades or concentrations can be produced by evaporation or hydration.

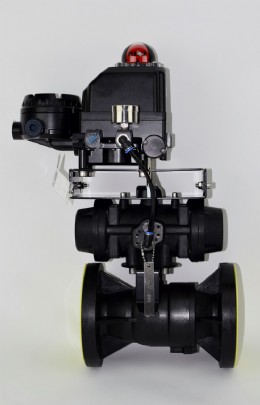

Steve explains, ‘Unfortunately, in the beginning of the wet process, there are so many particles of gypsum and silica in the fluid that the rubber lined membrane valves previously used have been shown to suffer from abrasion, and then phosphoric acid attacks the metal. This abrasion diminishes as the gypsum and silica are washed, but then the concentration of phosphoric acid also then increases, causing further challenges. Clearly the solution is Safi thermoplastics valves, as they can resist both the abrasion and the corrosion. A modified Safi valve was specified, with GRPP body, PVDF ball with an evacuation hole, a PVDF stem and modified PTFE seats.’

‘Similarly, another application involving a Fluorosilicilic acid plant was likewise improved using Safi diaphragm valves. Fluorosilicilic acid is an important by-product from the production of phosphoric acid, and can be neutralised with sodium hydroxide to form sodium hexafluorosilicate. The acid is also used to make aluminium fluoride, used in turn in the manufacture of aluminium. The fluorosilicilic acid is mixed with gypsum and is successfully processed with PPH diaphragm valves that can readily handle the slurry,’ he added.

Steve concluded, ‘Often a sulphuric acid plant is located next to a phosphoric acid plant. This is normally a hot process where thermoplastic valves cannot be used, but they are however ideally suited to the acid’s storage and transportation. And as the production of phosphoric acid needs a great quantity of industrial water, this is often collected from the sea and is cleaned of marine life and salt. Again, Safi has products ideally suited to this desalination application.’

Tel: 01202 624 618

Email: sales@safi-valves.com

Web: www.safi-valves.com

| Telephone: | 01202 624618 |

| Email: | sales@safi-valves.com |

| Website: | www.safi-valves.com |

| More information on the SAFI Ltd BVAA Member Directory Page |

Search related valve / actuator articles: SAFI LtdIssue 43Discharge ValvesCompany News

-web.jpg)