An Approach to Maximizing Gas Distributor Operations with Smart Grid Management Systems

Several years ago, gas distribution companies launched their first foray into value-driving technology when they began to adopt smart metering to improve the accuracy and efficiency of their billing. Now in various parts of the world, these companies are more willing to experiment with technology that can give operators the ability to monitor system parameters, manage the flow of gas through their network, and control individual stations from remote locations. Benefits include improvement in safety, reliability, operational efficiency, and profitability while giving operators greater visibility and control of their gas.

Smart Systems Components that Put Operators’ Priorities

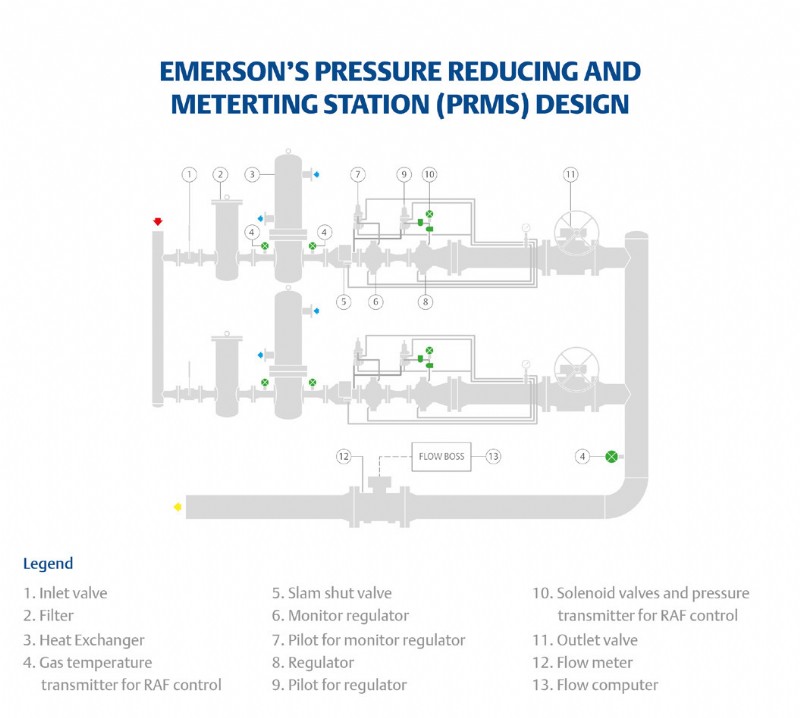

First To meet the challenges of the downstream natural gas industry, operators should work with a solutions provider who can provide smart system components that address safety, cost savings, reliability and efficiency. Such smart gas systems consist of a central unit that receives system parameters (temperature, pressure, flow), processes that information, controls pressure management equipment, and interfaces with control loops.

This system can be used at an individual station or for multiple pressure reducing and metering points across the distribution grid. An interface can control various components such as solenoid valves, pressure transducers and temperature sensors. Communication with existing networks is also vitally important for the success of any system upgrade. Local and remote communication capabilities (webserver, USB, Ethernet, GPRS, and others.) and the possibility of interfacing with an existing supervisory control and data acquisition (SCADA) system (through MODBUS, TCP/UIP Protocols) are desirable features of equipment in such networks.

Benefits of Smart Gas Systems

Enhanced Safety: The ability to remotely monitor and operate smart gas systems is one of the main advantages of this technology. Not only are operators able to manage the system quicker, but also require fewer trips to the field meaning fewer safety concerns from sending people to remote and potentially hazardous areas. This technology also addresses noise concerns by enabling maintenance personal to distance themselves from high noise levels, and by splitting the total flow into more lines, controlling the flow through each regulator and reducing the amount of emitted noise. To ensure public safety, similar equipment can be installed in odorant injection systems to reduce complexity of the process and to ensure an accurate mixture of gas is injected into the grid.

Gas Delivery Efficiency: The ability to estimate gas flow where no meter is installed and monitor other parameters (temperature and pressure) at multiple points allows accurate flow/pressure mapping across the grid. During standard operation, the user can use this information to properly balance the grid by adjusting pressure setpoints, thereby remotely accommodating seasonal changes in downstream demand.

Limit Oversizing Infrastructure: When building their infrastructure, distribution companies tend to oversize the regulating station because the demand downstream has yet to be established. When grid upgrades are considered, smart systems can limit oversizing. And as natural gas supply becomes more diverse -- for example the expanded use of biomethane -- new technologies can seamlessly balance various gas sources at grid injection points and manage gas quality for non-traditional gas sources with no change in system operating conditions.

Taking this a step further, control loops have been programmed to balance, locally and in real time, the supply/demand ratio. Additionally, control loops can collect data to use in predictive analytics and forecasting, which can later be used in elaborate predictive maintenance algorithms. This enables distribution companies to better utilize their manpower for maintenance tasks and operations that must be performed locally from the time of installation.

Environmental Stewardship & Cost Savings: Through remote monitoring and tighter control of system pressure, the average pressure in the grid can be lowered, thereby lowering stress on system joints and piping and limiting the risk of leakages and emissions. Therefore, end users are able to prolong the life of their investment while saving on cost due to lost product.

Results

Control systems developed by industry experts such as Emerson can generate continuous savings and even a return on investment in less than a year depending on the size of the network and the complexity of the system. At the network level, the system advances critical strategies of gas utilities through smarter grid management and savings in maintenance costs, lost gas and more efficient resource deployment. By embracing these new technologies and tapping into vast solution expertise in the space, distribution companies can reach peak operational performance while also improving their safety and environmental metrics in the process.

Tel: 0870 240 1978

Email: uksales@emersonprocess.com

Web: www.emersonprocess.co.uk

| Telephone: | 0870 240 1978 |

| Email: | uksales@emerson.com |

| Website: | https://www.emerson.com/en-gb/automation/home |

| More information on the Emerson Process Management Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Emerson Process Management LtdIssue 43ValvesSafety ValvesControl ValvesCryogenic ValvesSolenoid ValvesSafety Relief ValvesBursting DisksPilot ValvesEmergency Shut Down (ESD)Emergency Vent Valves (ESV)Butterfly ValvesPneumatic ValvesBall ValvesGate ValvesNon-Return ValvesDischarge ValvesProcess ValvesDiaphragm Valves / Pinch ValvesChoke ValvesDouble Block and Bleed ValvesCheck ValvesTrainingProtectionMaster ClassNeedle ValvesValve InterlocksRotary ValvesHydrantsGlobe ValvesCartridge ValvesComposite ValvesValve IslandsBreather ValvesPulse ValvesPress Fit ValvesIsolating ValvesBypass ValvesRadiator ValvesCapping ValvesPlug ValvesHydraulic ValvesAir Valves

-web.jpg)