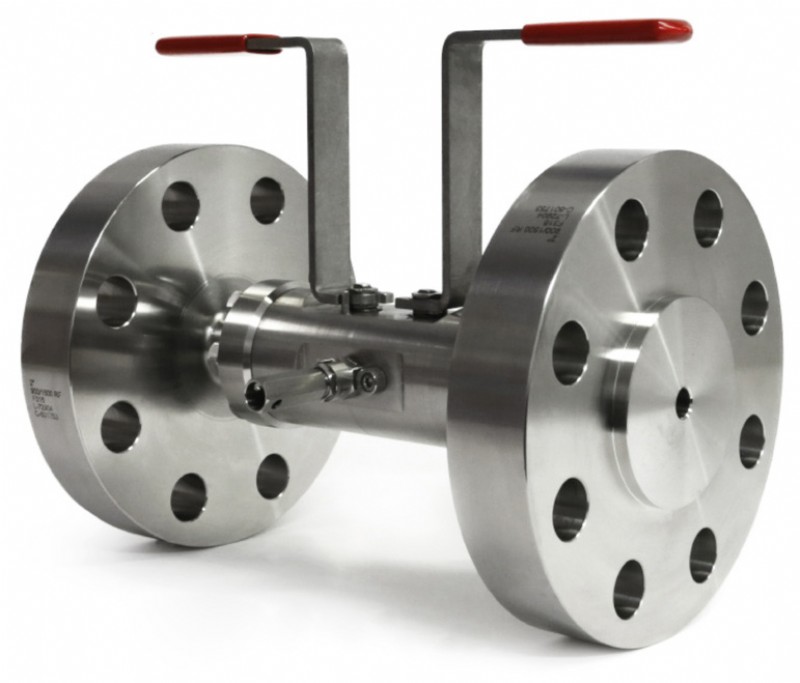

Introducing the Next Generation of Double Block & Bleed Valve Technology

The Alco Valves XC Range

Final Product

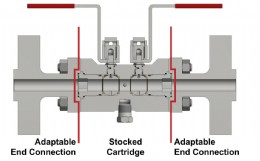

Stocked Cartridge

XC Construction

When fully assembled the XC valves are unlike any other DBB valve on the market. However, the Alco Research and Development team were able to challenge the conventional methodology of DBB design to create an innovative interchangeable valve solution. The XC compact design allows the centre module of the valve to be manufactured, assembled, tested and stocked without fitting the end connections, before the point of order placement. This means drastically reduced lead times for the benefit of the customer.

Alco Valves have invested heavily in the latest state of the art CNC machinery and other advanced manufacturing equipment which has supported the initiative to provide expedited deliveries for highly complex DBB technologies. This outstanding level of investment ensures that the company achieves operational excellence when meeting customer requirements.

Design Features:

Adaptable, Reliable & Robust;

Compact design for cost efficiency and weight;

Designed and manufactured in accordance with ASME standards;

A wide array of material configurations available;

A wide selection of end connections available;

Service temperatures from -46°C to 200°C;

Fire Safe;

Low Emissions;

Features 2 high performance floating pattern ball valves and a venting needle valve c/w NPT female vent.

Pressure Ratings Available:

ASME Class 150 to Class 2500

Bore Sizes Available:

13, 19, 25, 38 and 50 mm

You can also refer to the case study article detailing technical features, testing methods and qualifications which you can download from www.alco-valves.com

Tel: 01484 710 511

Email: uk@alco-valves.com

Web: www.alco-valves.com

| Telephone: | 01484 710511 |

| Email: | info@alco-valves.com |

| Website: | www.alco-valves.com |

| More information on the Alco Valves Group BVAA Member Directory Page |

Search related valve / actuator articles: Alco Valves GroupIssue 45ValvesDouble Block and Bleed Valves

-web.jpg)