Advantages of Rotary to Linear transmission in SAMSON Ringo axial valves

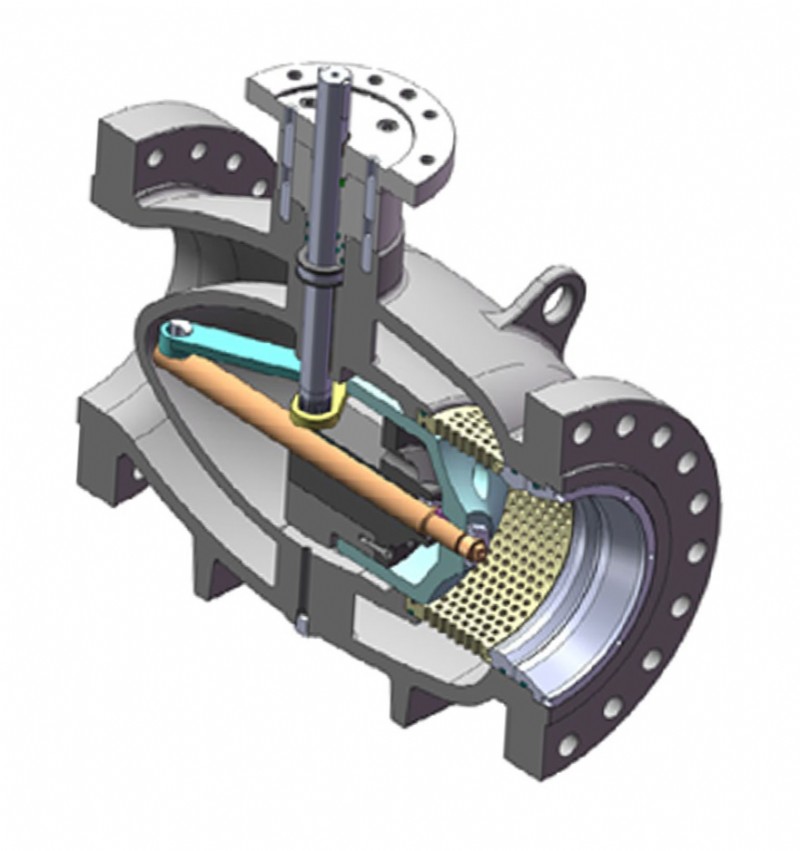

Section of a single-stage axial regulating valve

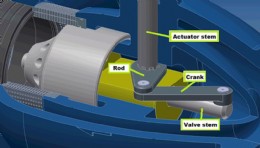

Main components of the rotary to linear transmission

The pressure drop is related to the geometry of the valve, that dissipates energy in the flow of the fluid circulating through it.

Part of the lost energy dissipates in reducing pressure and increasing velocity but some dissipates in vibration, noise and fluid turbulence.

Globe valves have different designs and solutions to prevent the energy from dissipating in the form of vibration and noise, which can become harmful to the process or material. However, regarding turbulence and loss of energy, they are not very efficient because of their complex geometry and lack or “aerodynamic” design.

The axial valve has a more “aerodynamic” geometry with the main objective of reducing energy loss through turbulence, so that for the equivalent size globe valve, the axial valve can obtain greater flow for the same pressure drop. This results in a reduction in weight, size and cost of product.

The complication of the axial valve is the movement transmission system from the actuator to the closing member. The simplest designs use linear-to-linear transmission systems by means of gearing, in which all the necessary force to move the closing member is generated by a linear actuator.

This article presents a rotary-to-linear design alternative that provides a mechanical advantage, thus reducing the force required by the actuator with a consequent reduction of actuator size and cost.

Brief Description of the Axial Valve

The axial valve’s regulating function, other than the axial movement of the closing member, is identical to globe control valves with a multi-orifice cage. In this type of control valve, the flow control to create the required pressure drop is obtained by opening a series of holes with a specific area.

Due to the valve’s construction, the axial valve closure is guided by the valve shaft and not by the cage. In this way an axial valve can be used for fluids with particulates since there is no risk of blocking the clearance between plug and the cage. In addition, it is possible to suit applications without a cage where it is intended to maximize the already greater flow capacity of the axial valve.

Motion Transmission System

The unique rotary to linear transmission system designed by SAMSON Ringo, is composed of a crank system that connects the valve shaft to the axis associated to the rotary actuator.

The valve shaft has a linear movement in the direction of flow while the actuation shaft has a rotating, quarter turn (90º) movement. This rotary movement is commonly used for other types of valves such as ball or butterfly valves.

The main advantage of this transmission system is the reduction of the torque required by the actuator when the force generated by the fluid is at its maximum. Also, the a distribution of forces across the elements of the linear to rotary transmission system results in a lower force/torque required by the actuator.

Conclusions

Due to the mechanical advantage gained by the crank system the rotary to linear transmission system has lower torque requirements when the valve is in the closed position when fluid force is at its maximum.

The force for rotary to linear mechanism is reduced to values less than half those required by a linear-linear mechanism.

Thanks to this unique transmission system it is possible to select a smaller actuator for the valve than with alternative systems, with resulting torque, size, weight and overall economic benefit in the final assembly of axial valve and actuator.

| Telephone: | 01737 766391 |

| Email: | sales-uk@samsongroup.com |

| Website: | uk.samsongroup.com |

| More information on the SAMSON Controls Ltd BVAA Member Directory Page |

Search related valve / actuator articles: SAMSON Controls LtdIssue 48ValvesSafety ValvesControl ValvesCryogenic ValvesSolenoid ValvesSafety Relief ValvesBursting DisksPilot ValvesEmergency Shut Down (ESD)Emergency Vent Valves (ESV)Butterfly ValvesPneumatic ValvesBall ValvesGate ValvesNon-Return ValvesDischarge ValvesProcess ValvesDiaphragm Valves / Pinch ValvesChoke ValvesDouble Block and Bleed ValvesCheck ValvesProtectionNeedle ValvesValve InterlocksRotary ValvesHydrantsGlobe ValvesCartridge ValvesComposite ValvesValve IslandsBreather ValvesTriple Offset ValvesPulse ValvesPress Fit ValvesIsolating ValvesBypass ValvesRadiator ValvesCapping ValvesPlug ValvesHydraulic ValvesAir ValvesAttemperatorsPressure Relief ValvesPressure Reducing ValvesSelector Valves

-web.jpg)