The best metal butterfly valve lining for demanding media?

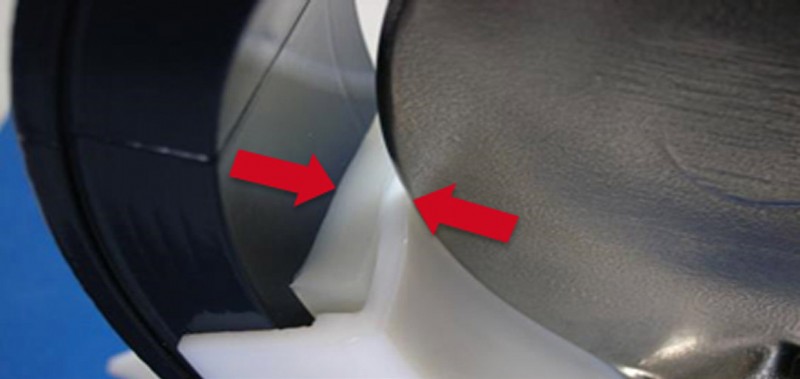

Figure 1 Special design liner support

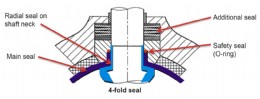

Figure 2 Special design shaft seal

Thermoplastic liners are also chemically inert. This is useful where high purity media is required, for example in pharmaceutical and semiconductor high purity water applications.

Common valve lining materials

The main lining materials used for metal valves are:

PTFE (PolyTetraFluoroEthylene)

PFA (PerFluoroAlkoxy)

TFMTM

PTFE liners are isostatically compression moulded from sintered chips. PFA linings are melt-processible which provides a far less permeable liner that can also be precisely moulded. TFMTM PTFE incorporates a PerflouroPropyl Vinyl Ether (PPVE) modifier to the PTFE. This is a more advanced material which has the following improvements to PTFE.

Reduced cold flow by factor of 3

Firmer polymer structure

Less permeable (factor 2) for chemicals and gases

Weldable

Smoother surface for machining

More transparent

Injection mouldable in special cases

The advantages of PFA and TFMTM lined butterfly valves are that they:

work well with most corrosive media to protect metal butterfly valve parts

can outperform more expensive alloy valves

are suitable for multiple-product processing lines being unaffected by media changes

are seldom affected by process temperature variations are virtually impermeable

PFA and TFM Lined butterfly valves

GEMά 490 series lined metal butterfly valves are available with a moulded PFA or TFMTM body liners. These linings are achieved using the latest plastic injection moulding machines to form a precise lining locked to the valve body. This is integral to the valves corrosion resistance.

Special silicon backing

As can be seen in Figure 1 the valve body liner is backed by a specially design silicon rubber backing which provides the forces needed for effective media sealing downstream.

Special shaft seal system

Chemical handling requires specialist sealing to prevent leaks to atmosphere. A special 4 fold shaft seal system (Figure 2) is also incorporated to prevent dangerous media leaks.

GEMά 490 series key features and benefits:-

High performance PFA or TFMTM lined metal butterfly valve

Wide range of sizes from DN40 to DN900 (1½″ 36″)

PN3/10/16 bar media rated (depends on size)

Suitable for use with temperatures up to +200 degrees Celsius

Pneumatic, Motorised, Manual and bare shaft options

Ideal for the distribution of Corrosive Chemicals, Effluents and Slurries

The valve of choice for High Purity water applications in API Pharmaceuticals and Semiconductor plant

Tel: 01925 824 044

Email: enquiries@gemu.co.uk

Web: www.gemu.co.uk

| Telephone: | 01925 824044 |

| Email: | sales@gemu.co.uk |

| Website: | www.gemu.co.uk |

| More information on the Gemu Valves Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Gemu Valves LtdIssue 50Related ProductsFluid ControlFRLsSealsCastingsSafety InterlocksSpringsSurface CoatingsCylindersSteam TrapsFlow MetersCoupling SystemsMaterialsWeld Overlay CladdingPressure RegulatorsInsulationPipingDrive SystemsVolume BoostersSensorsFittingsPosition MonitorsFilter RegulatorsManifoldsGasketsKey ManagementValve CoversSwitch BoxesForgersFastenersBoltingGaugesAlloysMounting Kits

-web.jpg)