Variable speed actuation opens up new application opportunities

High-precision multipart valve actuation

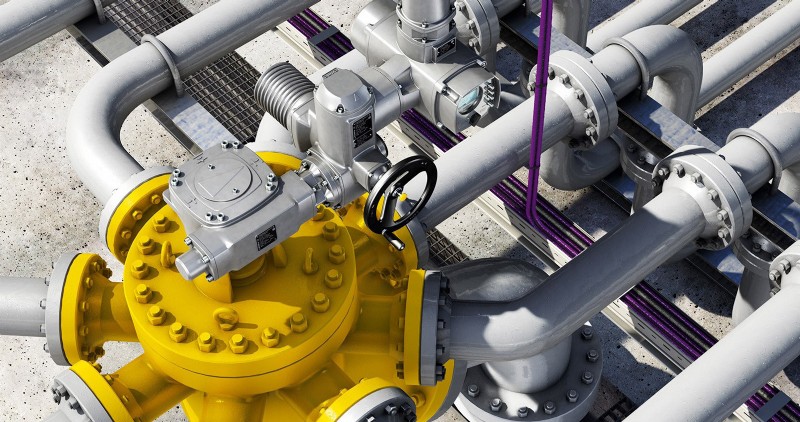

AUMA SAVEx ATEX-rated variable speed actuator

By slowing the actuation speed as the end point is approached a degree of self-cleaning is introduced that can reduce maintenance.

In addition, adjusting the motor speed helps with precision positioning applications. Here’s an example of how AUMA SAVEx variable speed actuation meets the needs of a technical oil and gas application.

AUMA offers a new high precision automation solution for multiport valves based on SAVEx electric actuators with adjustable motor speed. The actuators support up to 16 ports with a combination of short operating times and excellent precision, thanks to their variable speed motors.

Positioning accuracy is better than 0.3°, making the actuators suitable for the most challenging applications in this market. Switch valves with lift plug design are also supported.

Multiport valves find application in the oil and gas industry in sampling systems for multiple wellheads. Fluids from each well in turn can be directed to a single sampling system, allowing operators to monitor current production in detail. The positioning accuracy required makes this a challenging application for actuators.

AUMA’s SAVEx variable-speed actuators are ideal for this task. For rapid switching, the actuator motor runs at high speed over most of its travel. Just before the valve plug reaches the target port position, however, the speed is considerably reduced. By virtually eliminating overrun, this allows extremely precise positioning.

Switch valves with lift plug design require an even more demanding actuation solution since two different movements have to be coordinated: before the plug can rotate to the desired outlet it has to be lifted from its seat. This requires a second actuator. AUMA’s clever and simple solution is to use two actuators in a master-slave configuration that appears to the DCS as a single actuator. The intelligent actuator controls handle the complete sequence of movements and the safety interlock.

AUMA has also expanded its list of communication protocols supporting multiport and switch valve functionality: Foundation Fieldbus is now also available, in addition to Profibus DP, Modbus RTU and Modbus TCP/IP.

Tel: 01275 871 141

Email: mail@auma.co.uk

Web: www.auma.co.uk

| Telephone: | 01275 871141 |

| Email: | mail.uk@auma.co.uk |

| Website: | www.auma.co.uk |

| More information on the AUMA Actuators Ltd BVAA Member Directory Page |

Search related articles: AUMA Actuators LtdIssue 52Electric Actuators

-web.jpg)