Steam Sterilization of Solids

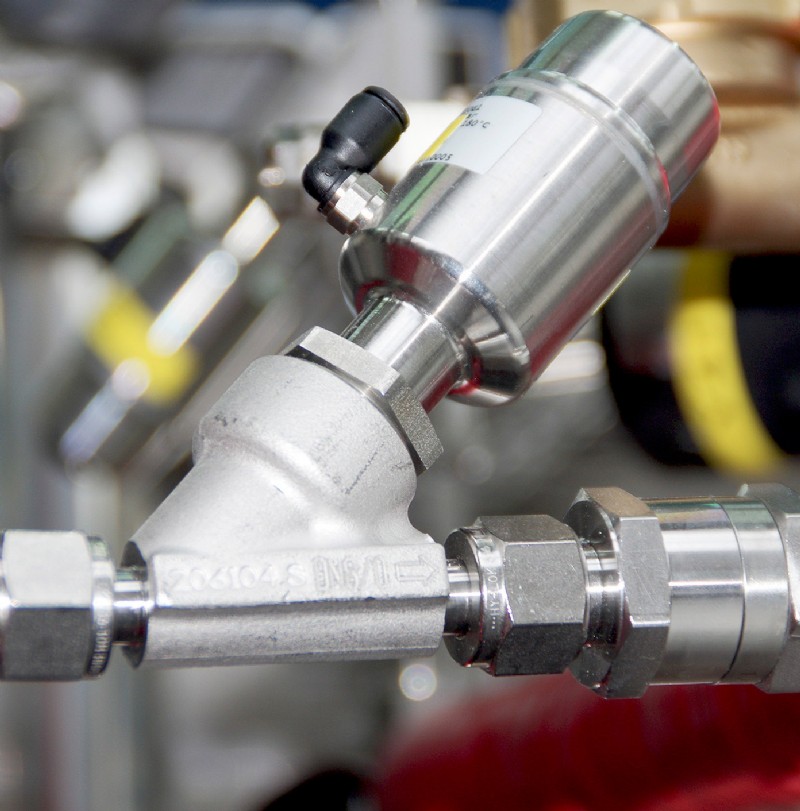

Figure 1 GEMÜ 550 globe valve

Figure 2 GEMÜ 550 globe valves in the flow lead

Figure 3 GEMÜ 555 globe valves for pure air

combined effect of steam and pressure.

The advantages of steam sterilization are as follows:

• effective cleaning method

• no toxicity

• no environmental impact

• no toxic residues on the sterilized product

• favourable cost-benefit ratio

Pharmaceutical companies use the steam sterilizers for example, to sterilize nutritive media, but also cages, animal feed and drink solutions within animal sciences.

There are specific requirements for the valves used in this application and GEMÜ 550 angle seat globe valves were selected as they are perfectly suited for cleanroom and CIP/SIP utilities process lines with their all stainless-steel actuator, spindle, body and even the switchbox or positioner.

The GEMÜ 550 valve spindle is sealed by a self-adjusting gland packing providing reliable valve spindle sealing even after a long service life.

A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

The sterilization process is divided into four steps:

1. Loading

2. Preparation, venting/evacuation of the chamber

3. Sterilization

4. Post-processing and drying of the sterilized product

Loading the sterilization chamber

The material must first be thoroughly cleaned to reduce bacterial exposure to a minimum even before sterilization. It must also be pressure and heat resistant.

Safe, reproducible steam sterilization which can be validated is only possible if there is free access to all external and internal surfaces of the product for the steam.

This involves opening containers or lab equipment and dismantling complicated instruments. Furthermore, the material may not be packed in the baskets too tightly.

Venting/evacuation

The sterilization chamber must be completely vented before the actual sterilization process takes place. Effective steam sterilization can only be ensured if the steam has fully displaced the air in the chamber.

There are several ways to achieve this which must be coordinated with the type of material to be sterilized. When sterilizing solids, fractionated pre-vacuum is a tried and tested method and is predominately used in modern sterilizers.

In this case, air is vacuumed out of the chamber using a vacuum pump through GEMÜ 550 angle seat globe valve, and then steam replaces the air.

This process is repeated several times. Finally, steam is added until the required operating pressure is reached.

Function of sterilization

If the saturated steam condenses on the sterilized material, thereby emitting energy, the protein in the cell is destroyed. It is essential that this heat is damp.

While it is possible to sterilize with dry heat, it requires considerably higher temperatures and longer exposure times.

Drying

Heating is started after the chamber has been evacuated. Normally, sterilization is carried out at 121°C for 20 minutes or at 134°C for 5 minutes.

Once this process is completed, the steam is vacuumed off and the chamber is evacuated to 120 mbar in order to dry the product. Depending on the product, drying is carried out with a drying vacuum or air pulsation.

Hot air drying is only required in rare cases. Any existing condensate evaporates due to the vacuum and is discharged via the vacuum lead and the GEMÜ 550 angle seat globe valves.

Pulsated drying, during which the air is fed into the system in phases, has proven itself to be a tried and tested method.

Before discharging, the chamber is cooled and pressurized with cooling water.

GEMÜ valves in the application

GEMÜ 550 angle seat globe valves are installed in the condensate line, airline and in the refrigerant circuit.

For control functions, the GEMÜ 550, 554 and 555 angle seat globe valves are being used together with the GEMÜ 762 and 751 ball valves for other processes.

Furthermore, the GEMÜ 560 check valves, GEMÜ 740 ball valve, and GEMÜ 488 butterfly valves are also being used in this application.

Types of steam as follows:

• Saturated steam (also known as pressurized steam): pure steam from boiling water.

• Unsaturated steam: arises when there is insufficient water, i.e. the saturated steam does not fill the total space.

• Hot steam (also known as overheated steam): arises when saturated steam continues to be heated without water.

• Wet steam: arises when saturated steam cools down, e.g. during a pressure reduction, and contains water particles.

• Steam-air mixture: arises when steams flows into an air-filled space and has a lower temperature with consistent pressure.

Tel: 01925 824044

Email: enquiries@gemu.co.uk

Web: www.gemu.co.uk

| Telephone: | 01925 824044 |

| Email: | sales@gemu.co.uk |

| Website: | www.gemu.co.uk |

| More information on the Gemu Valves Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Gemu Valves LtdIssue 53Steam Systems

-web.jpg)