James Walker helping to pioneer a change in critical subsea applications

The materials experts at the James Walker thermoplastics centre of excellence, based in Gourock, have been working with a number of customers recently on another such project which aims to reduce component weight in critical subsea applications.

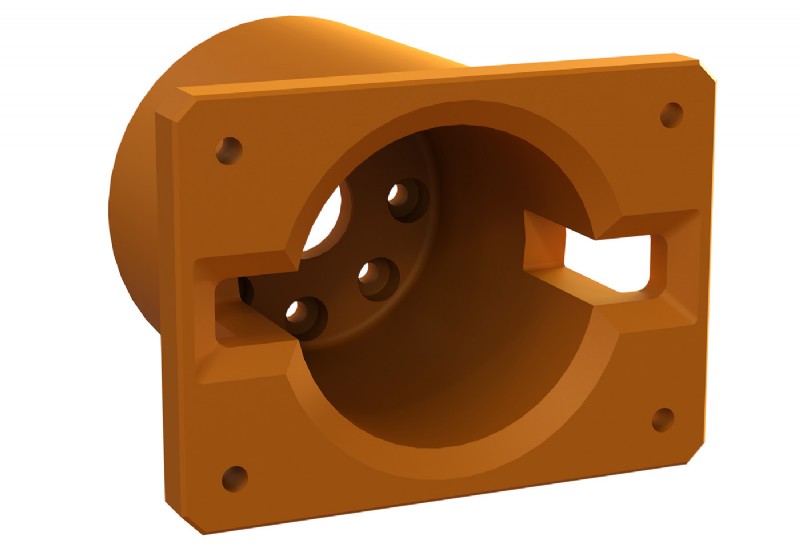

ROV torque buckets are commonly fitted in applications such as valve panels on subsea trees, control panels and manifolds as well as valves for actuation and have traditionally been manufactured in steel.

Having many years of experience in material replacement for multiple valve and oil and gas applications has allowed the James Walker team to identify this as a key area where an engineered thermoplastic substitution could provide numerous benefits.

Following discussions with customers, a design, prototyping and testing phase for the Devlon® ROV buckets was undertaken at the James Walker facilities in Gourock.

Devlon® materials are amongst the toughest and hardest wearing thermoplastics available, making them ideal for subsea applications, where they have been specified for critical applications for over 25 years.

The Devlon® V-API square-face Class 4 design weighs-in at 4.46kg in air, compared to a traditional metal bucket typically weighing between 15-20kg, thus offering a substantial weight saving when compared to the traditional steel design.

The robust construction is corrosion free, whilst the simpler manufacturing process eliminates the need for coating and welding normally associated with metal counterparts. The rigorous testing and development programme (validated by DNV) tested two standard designs to BS EN ISO 13628-8:2006 and qualified the design life for 30 years.

Furthermore, the buckets are fully recyclable and offer a lower carbon footprint than a metallic part.

In the event that customer-specific requirements may call for an alteration to standard design and mounting configurations, the team at James Walker is able to assist with design, manufacture and testing.

Andrew Hambleton, Global Product Manager, commented:

“We are seeing a lot of interest from customers looking to benefit from changing existing metal parts such as the ROV torque buckets to high performance thermoplastics and as always, we are excited to be able to offer our expertise in assisting with any development and testing required.”

Tel: 07730 760 948

Email: andrew.hambleton@jameswalker.biz

Web: www.jameswalker.biz

| Telephone: | 01270 536000 |

| Email: | sales.uk@jameswalker.biz |

| Website: | www.jameswalker.biz |

| More information on the James Walker BVAA Member Directory Page |

Search related valve / actuator articles: James WalkerIssue 53Seals

-web.jpg)