SAFi: The right choice of valves in the Wet section of Battery Production for Electric Vehicles

SAFI-Techlink pinch control valves (small blue valve) in use on the mixers of a battery manufacturer in China

Wet process of Battery Manufacturing

PPGF Ball Valve

PVDF V-port control ball valve

PPH Non metallic needle valve

The Global automotive battery market is expected to reach USD 95.57 billion by 2025 as the scope and its applications are rising enormously worldwide.

The rising number of electric cars on the road, high investment in research and development sector, and rising government initiatives to reduce carbon emissions are driving this global change.

All across the globe, car manufacturers are seeking solutions to increase availability of battery components and dozens of car battery plants will be built in the coming years.

Each battery plant has its own process for battery production, but for each process the cathode material is one of the main components and its key to unlocking the potential of the battery within the electric vehicle. This process can either be ‘wet’ or ‘dry’ and the wet process involves highly corrosive chemical fluids in the process of manufacturing.

This is where a robust solution in terms of non-corrosive piping and valves is required.

SAFI Valves supply piping and valve solutions to this industry which successfully solve the issues associated with corrosion within the wet process of battery manufacturing.

The challenges of the Wet process of Battery Manufacturing

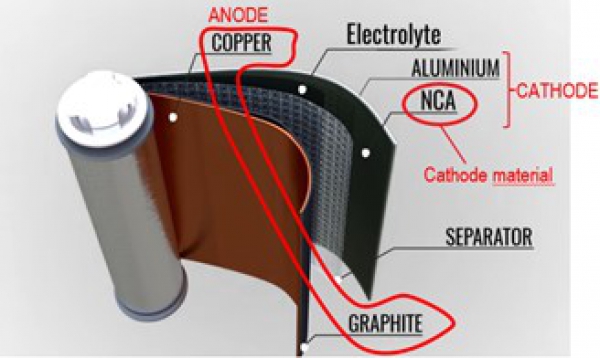

Battery cells are composed of an anode in copper covered with graphite, a cathode in aluminium covered with cathode material and electrolyte with a separator between the anode and cathode.

The wet process of battery manufacturing involves the production of Cathode materials.

Cathode materials are made of various blends such as for the most usual ones NMC (NCM) – Lithium Nickel Cobalt Manganese Oxide (LiNiCoMnO2), NCA – Lithium Nickel Cobalt Aluminium Oxide (LiNiCoAlO2), LMO – Lithium Manganese Oxide (LiMn2O4) that are mixed and then dried up.

The production of such blends involves the use of sulfuric acid, caustic soda, ammonia and sulfates of copper, nickel, etc…

Those fluids are very corrosive and abrasive, but the pressure and temperature are not exceeding 55°C or 4 bars. Additional to this, the process cannot tolerate undesired substances such as iron oxide, zinc, asbestos and PVC that come from damaged piping or valves and would pollute the blend in the mixers.

The solution of non-metal valves

The use of non-metal valves and non-PVC valves is highly recommended in the production of cathode materials to prevent pollution of the process.

SAFI valves in particular proposes on/off ball valves in PPGF (polypropylene glass fiber) that are perfectly suitable for the process and have been used successfully in battery plants.

Those valves have the advantage of durability and strength compared to other non-metalic valves, also called thermoplastic valves.

PPGF valves resist to the chemical attack of the fluids, they are twice as strong than the usual PPH valves and their compact two-piece design makes them among the most leak-proof thermoplastic valves in the world.

A factor that is not well known is that PPGF also has a good tolerance to abrasion.

For instance, PPGF is 30 times more resistant to abrasion than PTFE (Teflon) lined metal valves. The ball or the entire valve is also available in another thermoplastic called PVDF (PolyVinyliDene Fluoride), that is 100 times more resistant to abrasion than PTFE. Those valves can also be actuated with pneumatic or electric actuators.

The importance of control valves in the production of cathode material

The wet process of manufacturing cathode material also involves a careful dozing of chemicals and sulfates into the reactor where they are mixed, requiring the use of control valves.

Control valves must have the same capacity to resist corrosion and abrasion as the above on/off valve, and be able to provide regulation for very limited flow.

For such applications SAFI has developed two solutions with it’s partner Techlink: ball valves with a regulation V-plate and pinch valves.

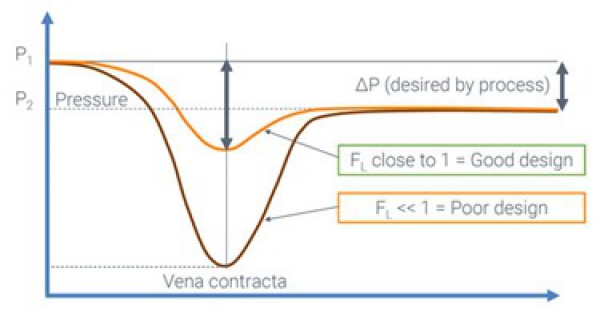

With a specific design, V-orifice ball valves have a pressure drop as shallow and precise as a globe valve.

The pressure drop in the “vena contracta” is characterized by the “Pressure Recovery Coefficient” FL of the valve.

The value of FL varies between 0 and 1. A value close to 1 means a smaller pressure drop.

The velocity in the Vena Contracta varies in the opposite way to the pressure drop. Globe and V-Orifice ball valves both have a 0,9 FL value and therefore have a lower maximum velocity in the Vena Contracta.

This analysis is even more true regarding needle valves (Fl value 0,95), therefore thanks to their unique design, our V-orifice ball and needle V-notch valves have a FL similar to Globe valves.

The characteristic curve must be adapted to the process. There are various “depth” of Equal% depending on the process data.

Our valves offer adapted orifice and needle profiles that are designed according to customer-specified process conditions for the best results.

The use of thermoplastic control valves also brings additional advantages, they are lighter and usually more economical than solutions with metal control valves.

For the battery industry that is seeking solutions all across the globe to industrialize its processes of manufacturing, SAFI and our global partner Techlink provide solutions that have proven their reliability in operation and help secure the wet section of the production of cathode materials.

For more information, check our website at: SAFI : Manufacturer of corrosion-resistant plastic valves (safi-valves.com)

| Tel No: | 01202 624618 |

| Email: | sales@safi-valves.com |

| Telephone: | 01202 624618 |

| Email: | sales@safi-valves.com |

| Website: | www.safi-valves.com |

| More information on the SAFI Ltd BVAA Member Directory Page |

Search related valve / actuator articles: SAFI LtdIssue 63Ball Valves

-web.jpg)