Cameron: Understanding the Health of your Valves

Author: Jeffery Joseph, P.E.

Digital Solutions Manager

Introduction

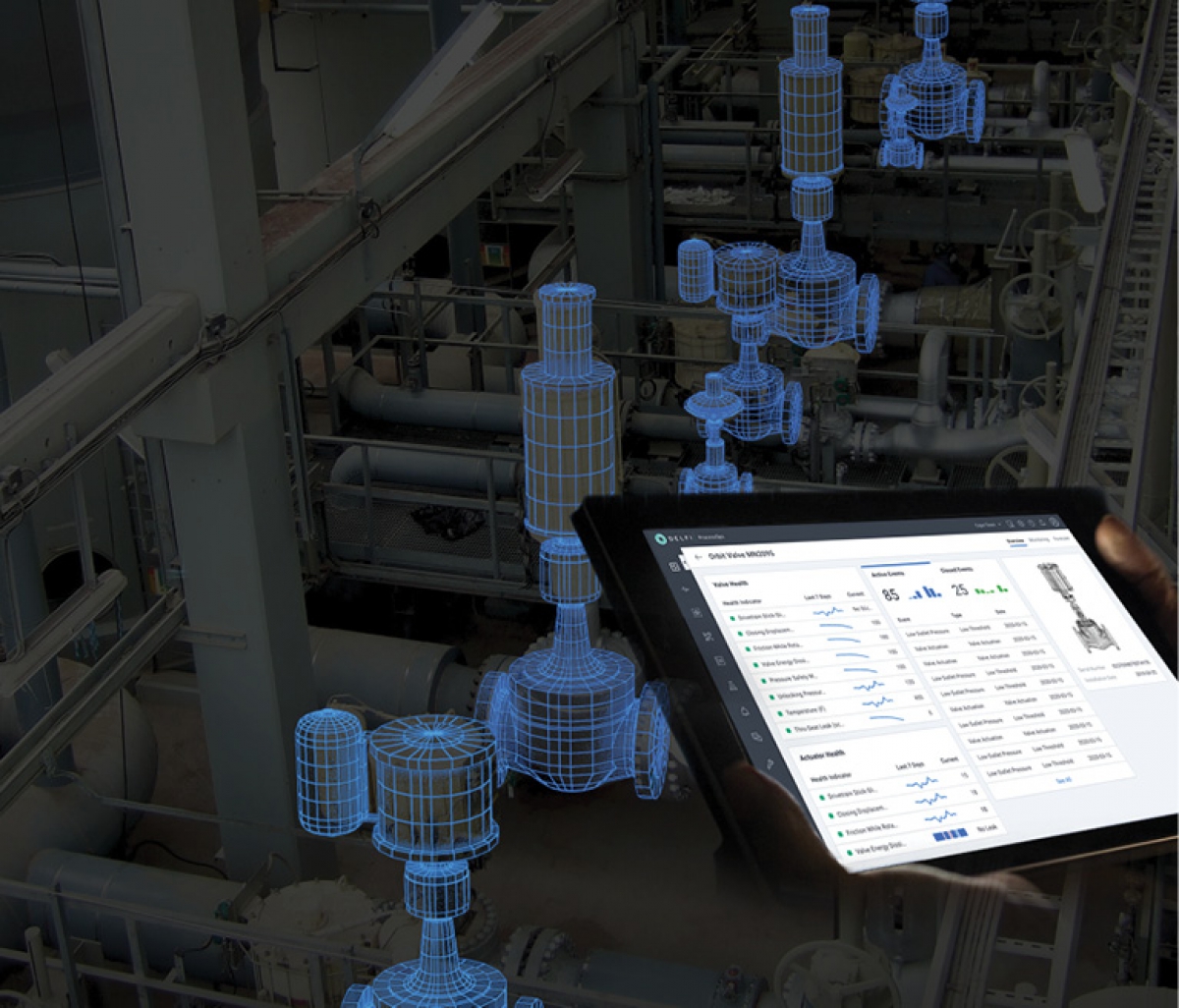

The oil and gas industry has embraced digitalization to increase operational efficiencies. In line with this, Schlumberger introduced Process Live* data-enriched performance service in 2019, which is an end-to-end service that combines data driven analytics with subject matter expertise and aftermarket services to provide an improved product lifecycle experience.

In 2021, Schlumberger launched Process Live Uptime Assurance for valves, an industry-first, digitally enabled rising stem ball valve.

Process Live Uptime Assurance for valves is available for Cameron’s Orbit* rising stem ball valve, which has a proven record of reliability in molecular sieve dehydration applications. Digitalization is the next evolution to increase reliability by providing clients with real-time valve data while in operation.

Why digitally enable a valve?

Digital enablement is most beneficial to valves deemed critical because they are essential to the safety of the client’s process and personnel.

Orbit valves switch on and off as part of the gas dehydration process to control the gas and regeneration cycles; just one Orbit valve failure can result in a shutdown and millions of dollars in lost revenue. Valve operation beyond the recommended parameters can cause unwarranted damage leading to unplanned shutdowns.

Real-time insights to the condition of the Orbit valve allows end users to understand if the valve is at risk of failing prematurely and proactively manage the valve service required. This avoids monetary losses due to production downtime and increased costs.

Process Live Uptime Assurance for valves

Process Live Uptime Assurance for valves delivers real-time insights of the condition of their automated ORBIT valve, which enables key operational decisions for servicing. Driven by machine learning and proprietary algorithms, the service also informs clients of what component is wearing and requires maintenance

Clients receive alerts and notifications of detected events related to the valve drive train health and can collaborate with SMEs or schedule a repair service. The system is also retrofittable and can be installed with no interference to operations or network.

Case Study

The system was initially deployed at a CO2 removal facility in the United States and provided value to the client within three months. Process Live was able to identify two separate Orbit valves operating outside recommended parameters: one valve was beyond recommended operational pressure and the other actuating too quickly. Both cases were immediately mitigated but without Process Live, the valves would have been likely to fail prematurely. Catching these issues early helped the client avoid millions of dollars in production loss.

| Tel No: | 01224 983500 |

| Email: | vmsalesabdn@cameron.slb.com |

| Website: |

| Telephone: | 01224 982000 |

| Email: | vmsalesabdn@cameron.slb.com |

| Website: | www.products.slb.com/valves |

| More information on the Cameron, a Schlumberger Company BVAA Member Directory Page |

Search related articles: Cameron, a Schlumberger CompanyIssue 64Ball Valves

-web.jpg)