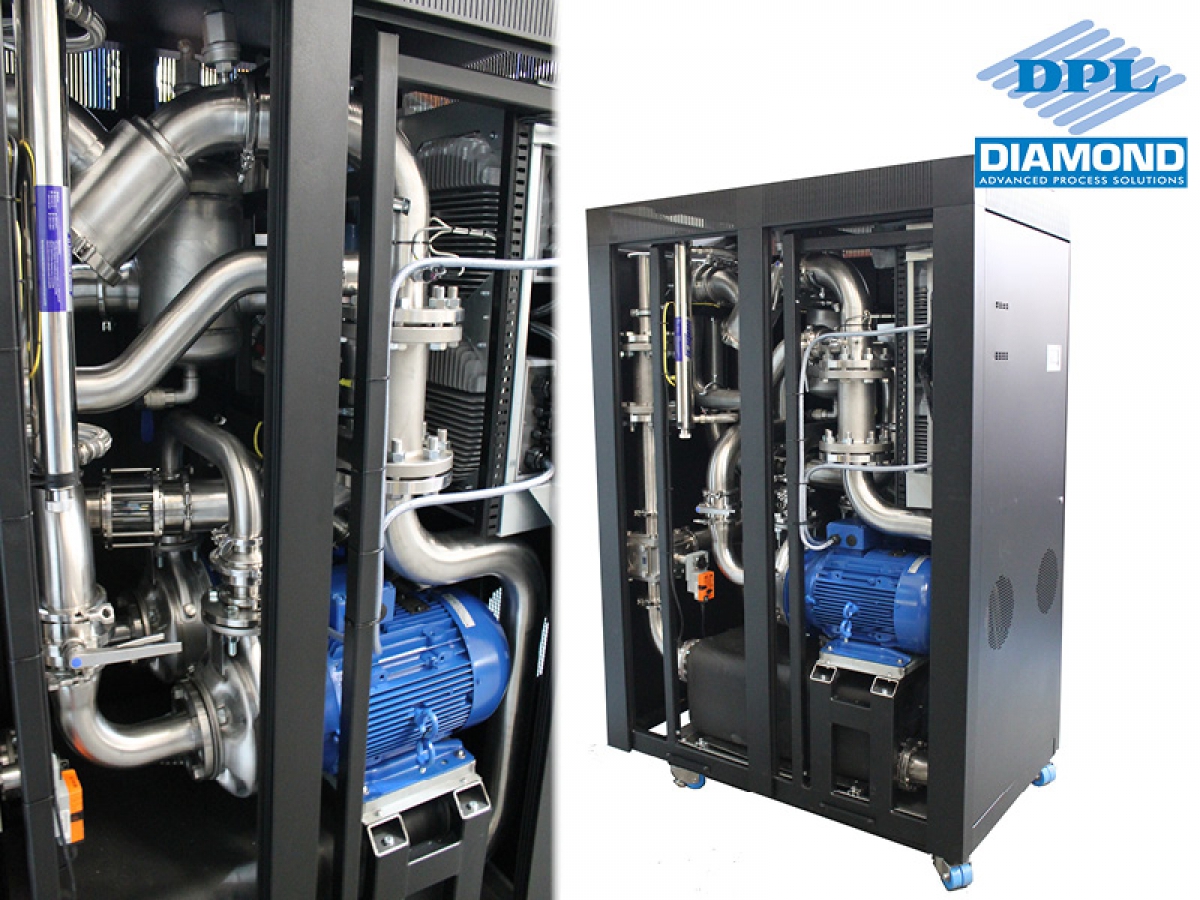

DPL Helps Create Worlds First Stainless Steel Coolant Distribution Unit

For High Performance Cooling

A major manufacturer of data centre cooling units had received a request from one of its customers to supply its coolant distribution units (CDUs) with stainless steel pipework instead of the traditional brass or copper.

Realising this was a gap in the market that needed filling, the manufacturer turned to Dairy Pipe Lines (DPL) to see if it could help. Given DPL’s extensive manufacturing knowledge of, and experience in, stainless steel pipework, it was in an excellent position to advise and guide the CDU manufacturer.

So began a four-year journey where DPL assisted its client in the design, manufacture and assembly of the world’s first stainless steel coolant distribution unit.

DPL’s initial input into the project was to help in the design of the stainless-steel pipework that would be installed in the CDU. Working as an extension of its client’s engineering team, DPL helped create a series of 2D CAD drawings and 3D models.

Design innovation

One of the challenges DPL faced was how to fit the new pipework into the existing space, given that stainless steel isn’t as malleable as brass or copper. Through its meticulous and methodical approach, the team successfully arrived at the first version of the CDU pipework that fitted perfectly into the same footprint.

DPL’s next task was to manufacture the set of pipework for the prototype unit, ensuring the kit was manufactured to the highest possible standard. DPL then assisted in the assembly and successful fitting of the pipework into the initial unit.

The unit was then shipped off to a major trade exhibition in the USA to demonstrate the first stainless steel CDU for high performance computing and enterprise data centres. Following the initial blueprint of the prototype design, DPL helped its client fix a number of bugs and resolve a few issues in order to create the optimum design. Once everyone was happy with the final result, the team was then in a position to embark on full-scale manufacture.

High quality, high purity

Switching from brass to stainless steel offers a marked increase in quality and purity that had never been available in this market before. For example, stainless steel pipework in CDUs means improved performance, as the coolant fluid flows more efficiently through stainless steel pipes, compared to brass or copper. Another advantage is lower maintenance costs as the coolant fluid doesn’t need to be filtered or changed as frequently. A further benefit is that stainless steel is resistant to both corrosion and leaks.

An extension of the client’s team

After the unit was unveiled at the exhibition, orders flowed in from around the world and DPL was asked to manufacture 50 kits, destined for end customers located in Australia, Japan and the United States.

Andrew Sharp, Manufacturing Manager at DPL and part of the team who worked on the CDU project, said: “As well as becoming part of our client’s design engineering team, working on the design concepts, we also helped with the ongoing manufacture and assembly of the pipework units. We even became part of their purchasing department, buying the various components we needed in order to build our stainless steel kits. This puts us in a strong position to help other manufacturers of large data centre cooling systems who are looking to benefit from the advantages of stainless steel pipework in their units.”

Why DPL?

Design acumen: measured approach, coupled with in-depth experience, when helping with the design stage of the project.

Prototype skill: ensured the first pipework kit was manufactured to the highest possible standard for the exhibition and was also fit for purpose.

Problem solvers and trouble shooters: worked alongside the client to help with all the changes required to make the unit operate at optimum efficiency and work rate.

Full scale manufacturing ability: set up a bespoke manufacturing cell to ensure manufacture of two kits each month, to supply market demand.

Dedicated account manager: daily one-to-one contact with the client, working across time zones, to provide a high level of personal service, ensuring all project issues were overcome and all deadlines met.

Industry knowledge: extensive understanding of HVAC/data centre cooling requirements and deadlines, to supply the growing market in high purity stainless steel HVAC/data centre cooling systems.

“DPL have been able to adapt to our stringent requirements in a timely and professional fashion. The quality of their work is of the highest standard. They are valued contributors to our development effort and I would very much recommend SFL for mission-critical applications.” – Mat Hery, Product Manager.

Dairy Pipe Lines Ltd

Tel: 0121 521 2020

Web: www.dpluk.co.uk

Email: n.whittingham@dpluk.co.uk

| Telephone: | 01799 520188 |

| Email: | dairypipelines@dpluk.co.uk |

| Website: | https://www.dpluk.co.uk/ |

| More information on the Dairy Pipe Lines LTD BVAA Member Directory Page |

Search related valve / actuator articles: Dairy Pipe Lines LTDIssue 65Miscellaneous

-web.jpg)