Using analysis to understand your system in a High Pressure High-Temperature Environment

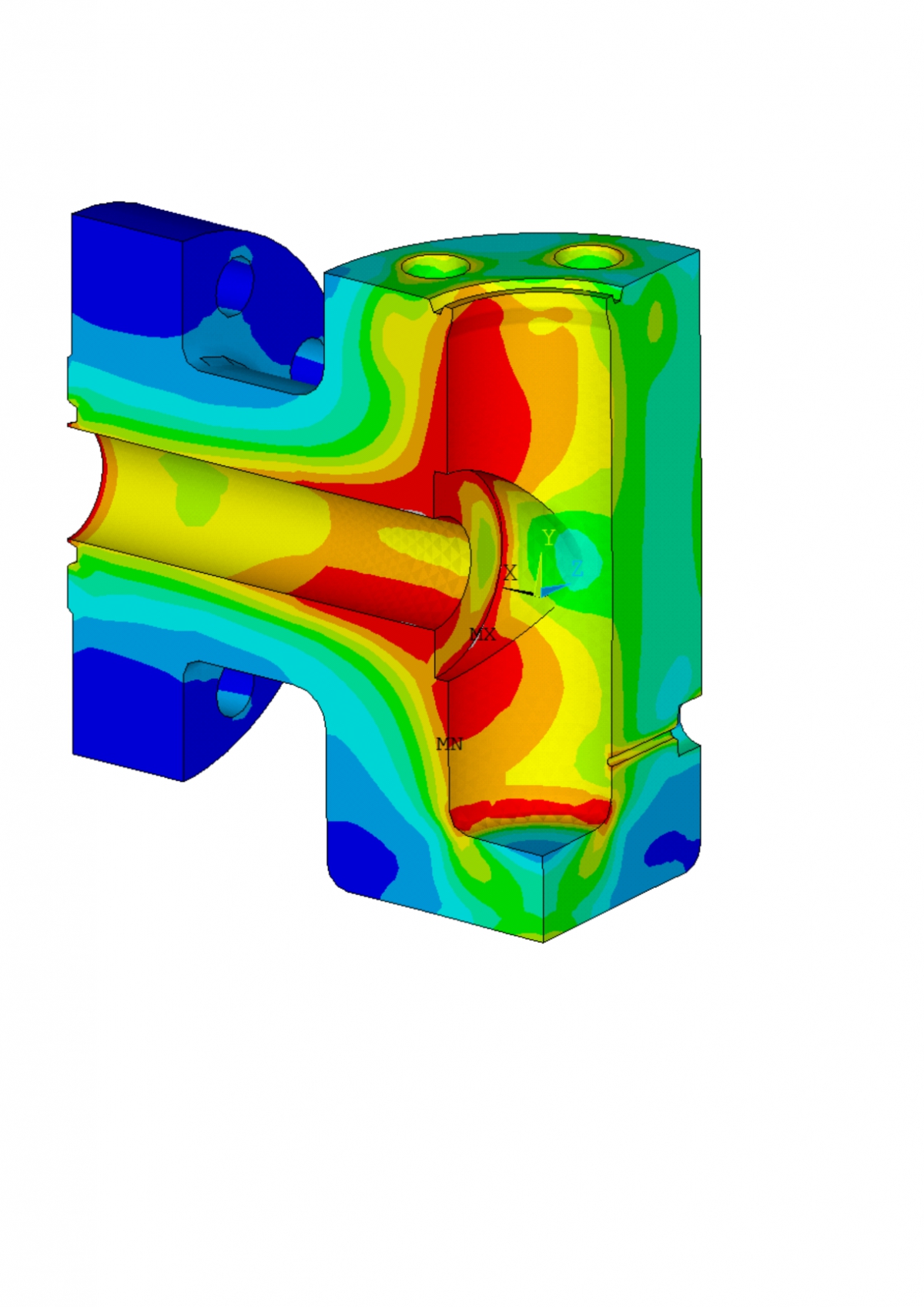

Definition of the critical location for the fracture mechanics assessment.

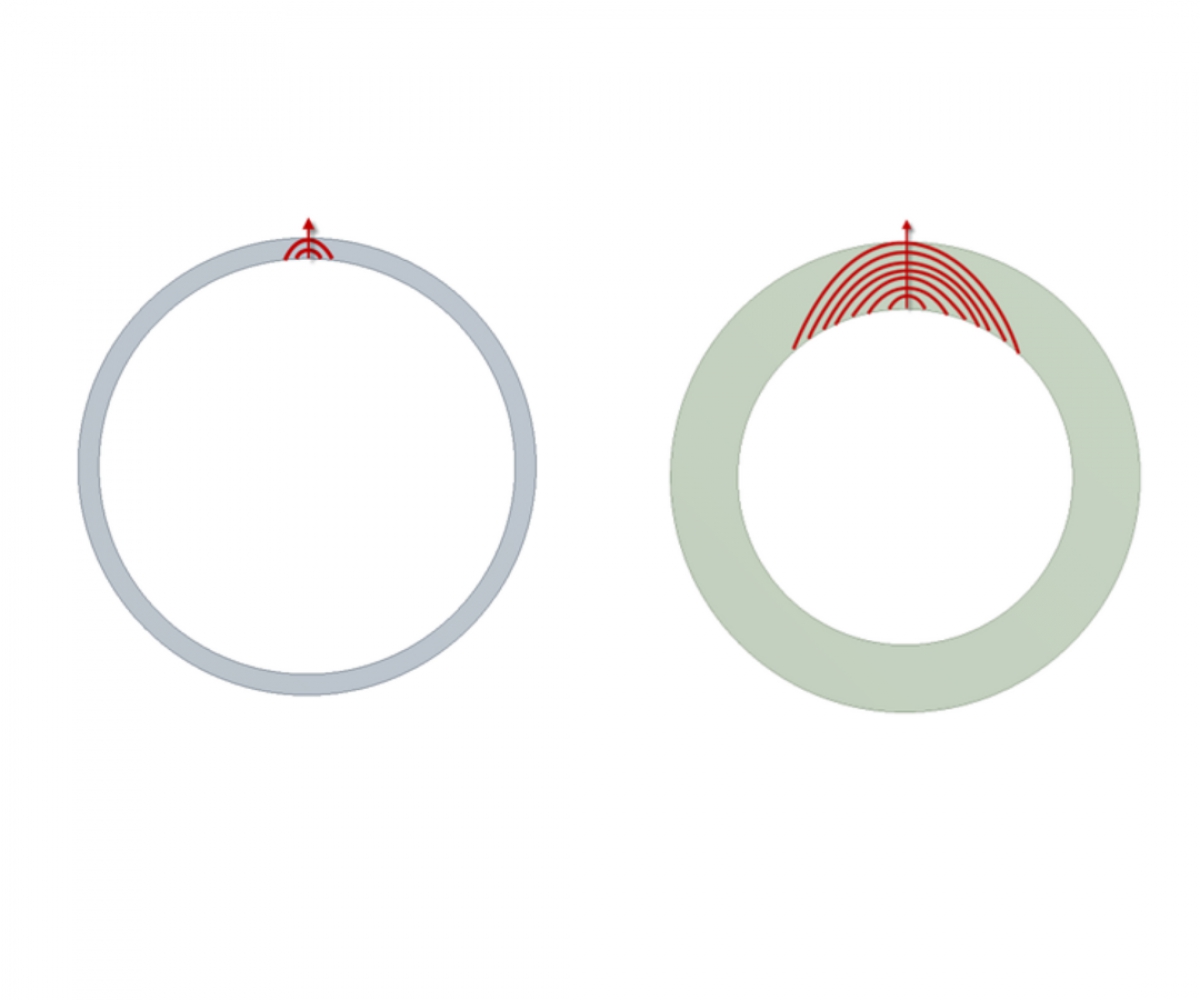

Leak before burst vs. fast fracture

Scan the QR code for the HPHT Webinar by PDL Engineering Manager Richard Farnell

The analysis experts at PDL Engineering Group have worked on many interesting and challenging valve and actuator projects to solve the most complex problems for clients who rely on them to validate, understand, test and optimise their systems.

The terminology ‘High Pressure High Temperature’ (HPHT) has been around for several years in the deepwater industry. The validity of these new ventures was enhanced by the bounce-back after the downturn, which saw a significant reduction in the field development costs and development times. The American Petroleum Institute (API) recognised the need to develop ‘design guidelines’ with the first publication of API 17TR8 in February 2015. Since then, the development and interest has gained momentum, with the third edition of TR8 published in July 2022. Despite the familiarity of this terminology, the challenges of these systems are not to be underestimated. The validity of classical methods to evaluate thick wall structures has been found to be non-conservative and has led to the recommendation of complex analytical methods to validate designs.

Engineers need to have a clear and concise understanding of how to qualify their product to the HPHT design guideline API 17TR8 in a timely and a cost-effective manner. This is an area that PDL engineers have extensive experience and expertise. Since 2015, they have worked closely with a number of clients to develop and validate their subsea equipment for the harsh HPHT environment and the scrutiny of third-party review. The PDL analysis team understand areas of concern can arise at bore intersections and managing the benefits of autofrettage (internal bore yielding). They have made design recommendations when areas of the design do not meet the fatigue life and have developed a suite of Fracture Mechanics solutions for common geometries found in pressure containing equipment.

Interested to learn more? Watch the HPHT webinar, presented by PDL Engineering Manager, Richard Farnell CEng MIMechE which is available in the unrestricted knowledge library on the PDL website. This technical webinar provides a clear and concise understanding of HPHT design guidelines in 30 minutes. You will gain:

- An overview of the API 17TR8 design guideline.

- A description of the qualification options, i.e., API 6A/API 6X/API 17D, ASME VIII D2 (linear), ASME VIII D2 (nonlinear), ASME VIII D3 (nonlinear).

- Guidance on the respective design margins, product specification levels (quality control requirements) and limits of validity.

Highlight from the webinar feedback:“Overall a very insightful and concise presentation. The part explaining the difference between leak-before-burst and fast-fracture-failure was the best explanation I’ve ever heard!"

To contact the PDL experts email: solutions@pdl-group.com telephone: 44 (0) 1 434 609 473 or connect on LinkedIn: PDL Group (Europe) or visit their website: www.pdl-group.com

| Telephone: | 00 44 1434 609473 |

| Email: | solutions@pdl-group.com |

| Website: | www.pdl-group.com |

| More information on the PDL Solutions (Europe) Ltd BVAA Member Directory Page |

Search related valve / actuator articles: PDL Solutions (Europe) LtdIssue 79ValvesActuators

-web.jpg)