GESTRA solutions for power plant drain systems

Enhancing the flexibility and reliability of your power plant by using a well-designed drain system.

Environmental regulations and economics are altering the face of power production. The importance of renewables such as wind and solar continues to increase; however, they are discontinuous and can affect network balancing.

Conventional fossil fuel power plants, designed for operating at base load, are now expected to adapt to variable loads and demand fluctuations.

Therefore, power stations must be able to start-up and shutdown more frequently, operate over shorter periods, run at minimum load, and rapidly change generation output.

Boiler, turbine, and steam line drainage is a key start-up application enabling safe and reliable plant operation, preventing water induction in the steam turbine and water hammer in the steam piping system.

When a higher frequency of start-ups and quicker start-up times are required, avoiding leakage from the steam and water cycles is essential in reducing thermal waste as well as enhancing productivity.

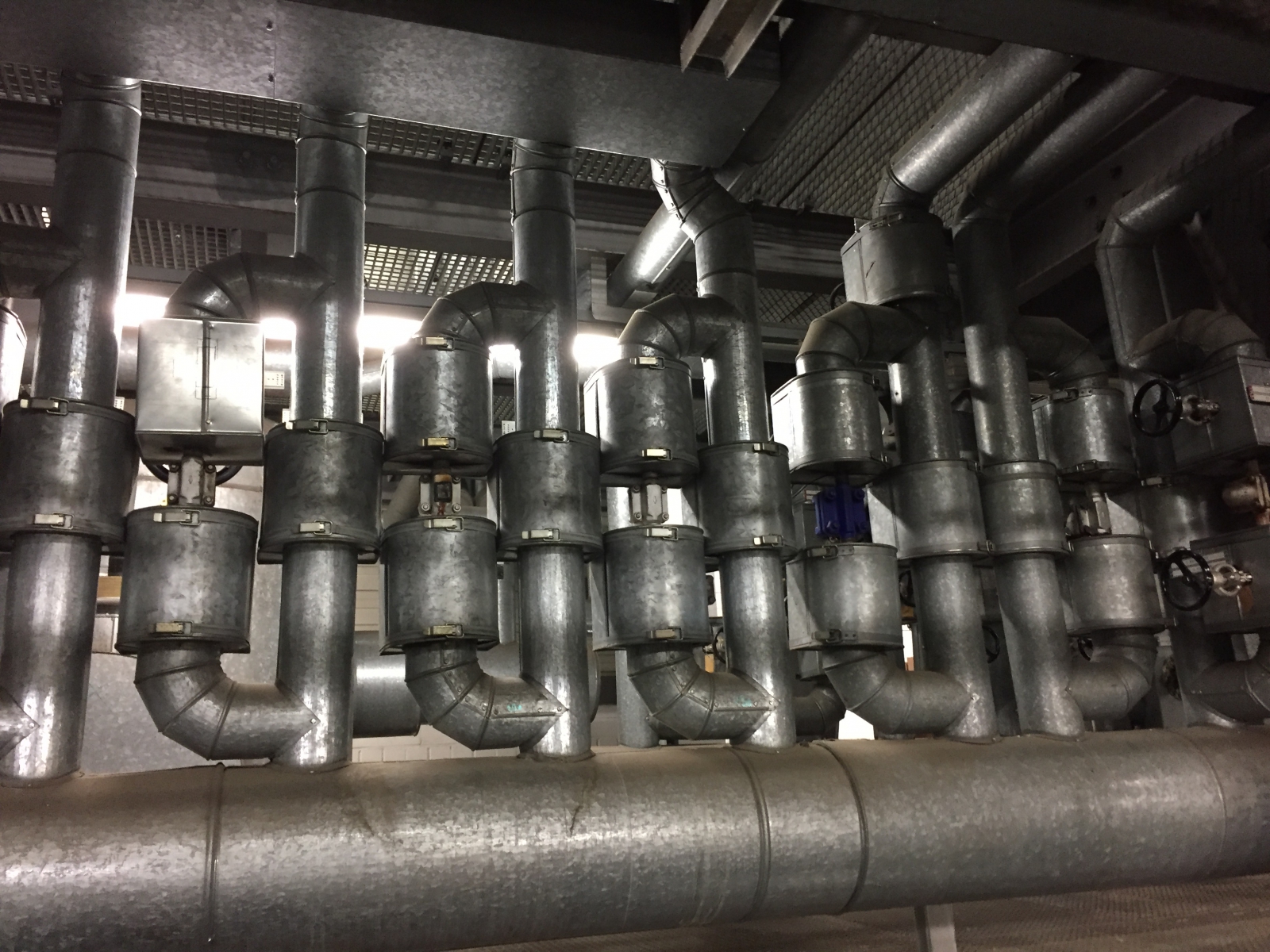

The drain system must be duly designed and sized: this includes drain pots and correctly sized fittings located at low points of the steam lines and before every upward change of direction.

Dirt collectors are recommended as well to prevent the drain valves from being damaged by welding beads, magnetic particles, drilling chips, etc. Drain valves must be duly designed and sized: not only do they discharge condensate, but they often simultaneously heat the pipeline systems. This causes the flow medium (cold condensate) to change in a two-phase flow from boiling liquid with saturated steam to hot steam. The evaporating condensate generates extremely high flow speeds inside the valve, placing special demands on the endurance of the internal components.

This is why drain valves must be very robust and wear-resistant, capable of handling a bi-phasic mixture of water and steam at high velocity and high differential pressure, built with the correct metallurgy. More importantly, they should be able to grant a zero-leakage tight shut-off, since during the normal operation the valves are closed.

Steam traps are critical as well. For instance, turbine drain lines, if not constantly drained with a steam trap, can be subject to the condensate banking up that can cause severe damage to the steam turbine internals, such as thermal shock cracks of the turbine blades.

Finally monitoring systems such as level probes, able to detect condensate, are critical in some cases like the cold reheat line drainage.

Your drain application system is too important to leave to chance. Contact us today for expert advice on yours:

Website: https://www.gestra.com/global/en-GB/industries/power-generation

Email: sales@uk.gestra.com

Tel: 01635 46999

| Telephone: | 01635 46999 |

| Email: | enquiries@uk.gestra.com |

| Website: | www.gestra.com |

| More information on the Gestra UK Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Gestra UK LtdIssue 81Valves

-web.jpg)