Fine Wire Fine Control

At Clifford Springs we are constantly pushing boundaries and looking to find new ways of solving customer problems.

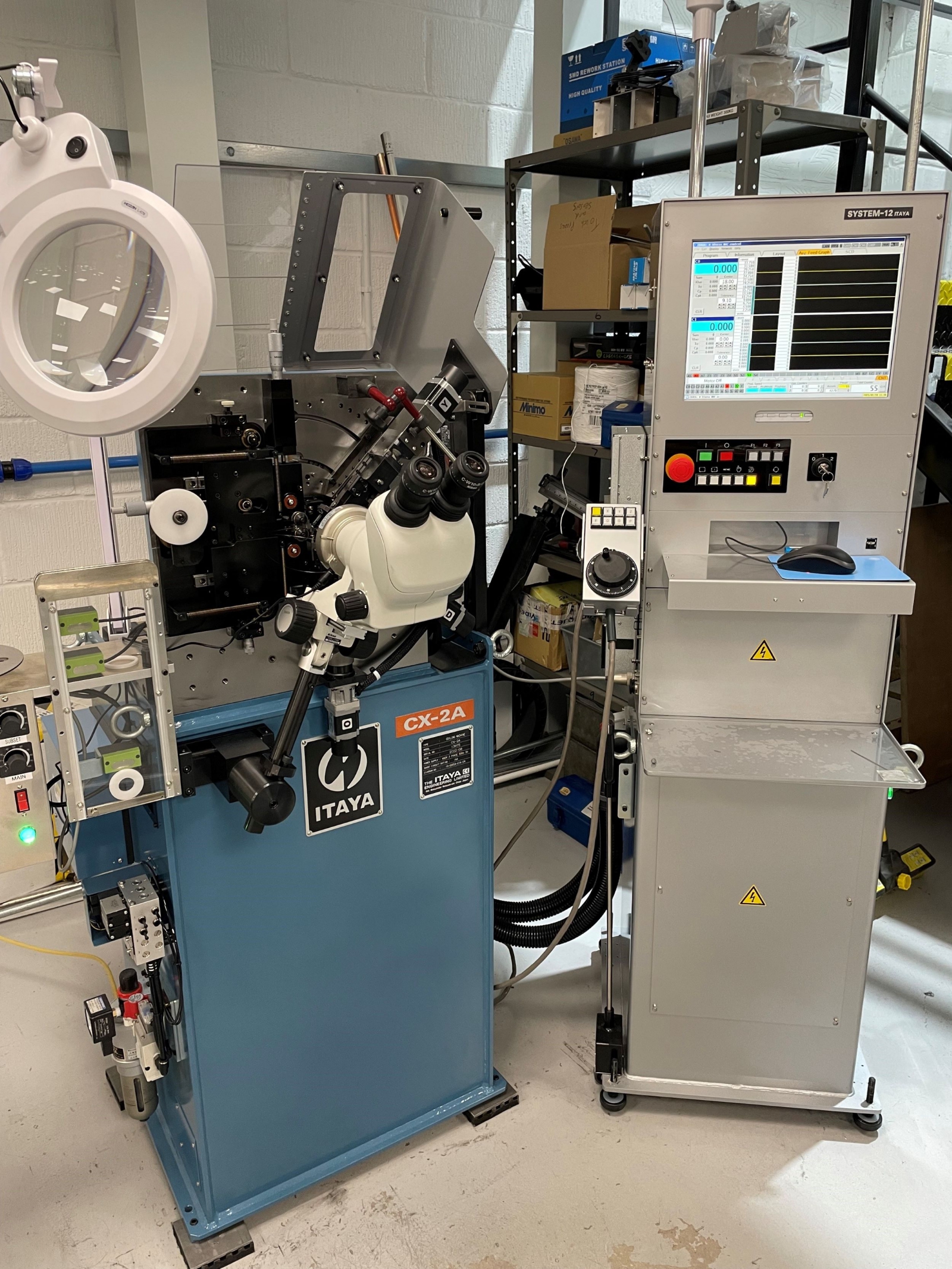

Sometimes that’s innovating springs, and other times it means investing in new machinery such as our new Itaya CX2.

This machine allows us to coil extremely fine wire. We can work with wire from 30 microns to 200 microns on the same machine.

This is our second Itaya CX2. We’re the only company in the UK with these machines, so the only one that can produce such fine wire.

This Itaya CX2 is a 6 axis machine which means that each of the 6 servo motors can be independently computer controlled to 4 decimal places.

In layman’s terms, we can control the tiniest of adjustments and be confident that each coil will be a perfect repeat of the previous one.

The more control we have, the more accurate the coil, so the better quality we can guarantee on every spring.

The smallest spring we’ve produced on this machine so far was just 1mm long. Just imagine the medical equipment that needs springs that small. And imagine the leaps that can be made in the designs of medical equipment as a result of being able to source springs that small.

And it’s not just compression springs that we coil on the Itaya CX2. We also make anti extrusion and helical springs, as well as canted coil, which has a vastly superior load to deflection ratio. It’s particularly good for latching systems where a constant force is needed.

And whether you want those fine coils in stainless steel or exotics alloys, we can create what you require.

So, if you’re looking for quality springs in fine wire, particularly for use within medical equipment, get in touch with us today.

|

Tel No: |

01527 62876 |

|

Email: |

|

|

Website: |

| Telephone: | 01527 62876 |

| Email: | sales@cliffordsprings.co.uk |

| Website: | https://www.cliffordsprings.com/ |

| More information on the Clifford Springs Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Clifford Springs LtdIssue 81Seals

-web.jpg)