AUMA: Preventing Water Hammer with Variable Speed Actuators

Brine wellhead with associated pipework and installed actuator

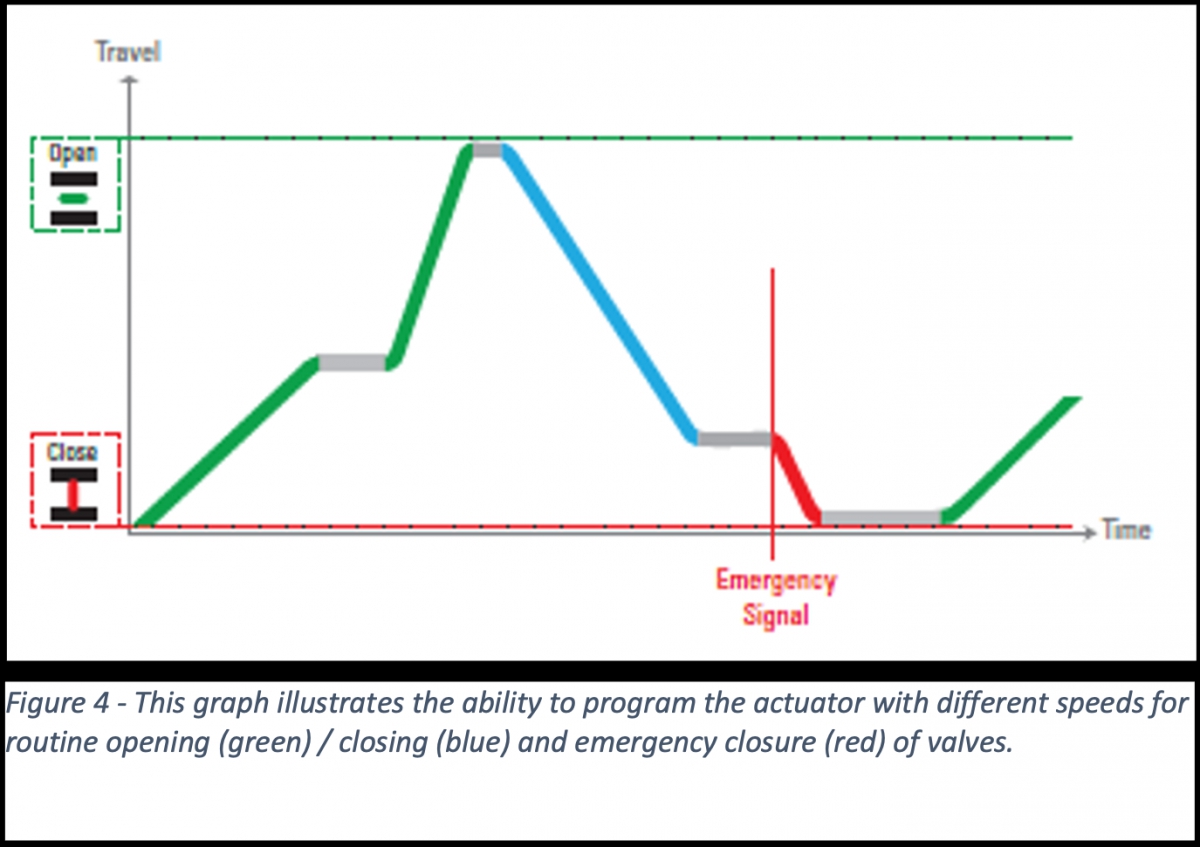

This graph illustrates the ability to program the actuator with different speeds for routine opening (green) / closing (blue) and emergency closure (red) of valves.

Water hammer can be a major concern in pumping systems and should be a consideration for designers. If not addressed it can cause a host of issues, from damaged piping and supports to cracked and ruptured piping components. At worst, it may even cause injury to plant personnel.

AUMA Actuators Limited offers a range of high performance actuator solutions capable of accurately and sympathetically controlling the opening and closing speed of valves and penstocks, delivering significant benefits in terms of flow control, reduction of water hammer and calm network performance.

What is water hammer?

Water hammer can occur with any fluid inside any pipe, but its severity varies depending upon the conditions of both the fluid and pipe. Water hammer happens when there is a surge in pressure and flow rate of fluid in a pipeline, causing rapid changes in pressure or force. Very high pressures can result in pipeline failure, such as leaking joints or burst pipes. Support components can also be subjected to strong forces from surges or sudden flow reversal.

Water hammer can be a significant issue in many applications. Valve seats may suffer if they are driven hard to their end positions whenever the valve is closed. A variable speed actuator gives the control engineer the opportunity to specify the speed of actuation at different points in the cycle. Variable speed actuators can be set so that the valve moves quickly through the majority of its cycle, slowing down as it nears the close position, minimising water hammer problems and extending the life of the valve seat. For emergency situations a ‘fast close’ speed can still be specified.

How does water hammer occur, and what are the consequences?

The importance of controlling water hammer in pumping stations is widely recognised by utilities and pumping stations. Increased pressure occurs every time a fluid is accelerated or impeded by pump conditions, or when a valve position changes. In normal operating conditions this pressure is small, and the rate of change is gradual, making water hammer practically undetectable. Under some circumstances, significantly increased pressure may be created, and forces on supports can be great enough to exceed design specifications. Rapidly opening or closing a valve causes pressure transients in pipelines that can result in pressures well over steady state values, causing water surge that can critically damage pipes and process control equipment.

Preventing water hammer

Typical water hammer triggers include pump startup/shut down, power failure and sudden opening/closing of line valves. A simplified model of the flowing cylindrical fluid column would resemble a metal cylinder suddenly being stopped by a concrete wall. Solving these water hammer challenges in pumping systems requires either reducing its effects or preventing it from occurring. There are a number of solutions system designers need to keep in mind when developing a pumping system. Pressure tanks, surge chambers or similar accumulators can be used to absorb pressure surges, which are all useful tools in the fight against water hammer. However, preventing the pressure surges from occurring in the first place is often a better strategy. This can be accomplished by using a variable speed actuator to control the speed of the valve’s closure rate at the pump’s outlet.

Advantages of Variable Speed Actuators to Mitigate Effects of Water Hammer

Improving valve modulation is one of several solutions that should be considered when addressing water hammer concerns in a pumping system. Variable speed actuators and controls provide pump system designers the flexibility to continuously control the valve’s operating speed and accuracy of reaching setpoints. This makes variable speed actuators the perfect solution to reduce the chance of water hammer.

Additionally, emergency safe shutdown can be provided using variable speed actuation. With the capability of continuing operation using a pump station emergency generator, the actuation technology can offer a failsafe option. In other words, if a power failure occurs, the actuator will close in emergency mode in various speeds using power from a UPS system, allowing for the system to drain. The positioning time curves can be programmed individually for close/open direction and also for emergency mode.

The advancement of actuators and their controls provide opportunities to use them for the prevention of water hammer. The following example explores how addressing water hammer was a key requirement. A linear characteristic was essential for flow control from a high-volume pump.

Variable Speed Actuation - Process Control and Pump Protection

A chemical company in Cheshire operates several hundred brine wells, each using pumps to transfer brine from the well to saturator units. The flow is controlled using pump delivery recycle butterfly valves driven by actuators. Under normal operation, when a reduced flow is detected, the actuator which controls the valve is opened over a period of 80 seconds. However, if a reverse flow is detected, the valve needs to be closed in ten seconds to protect the pump. Different actuation speeds are required for opening, closing and emergency closure to ensure protection of the pump.

AUMA’s installed variable speed actuator is able to provide up to seven different opening/closing speeds. These can be programmed independently for open, close, emergency open and emergency close.

AUMA variable speed multi-turn actuators are an excellent solution for sympathetic control of open-close duty situations. This type of actuator design can provide a soft start from the beginning position and soft stop upon reaching the end position. This level of control avoids mechanical pressure surges (i.e., water hammer) that can contribute to premature component degradation. The variable speed actuator’s ability to provide this kind of control positively impacts maintenance intervals and extends the lifetime of system components.

For more information contact Colin Borrows colin.borrows@auma.co.uk or visit www.auma.co.uk.

Contact details:

T: 01275 871141

| Telephone: | 01275 871141 |

| Email: | mail.uk@auma.co.uk |

| Website: | www.auma.co.uk |

| More information on the AUMA Actuators Ltd BVAA Member Directory Page |

Search related valve / actuator articles: AUMA Actuators LtdIssue 85Electric Actuators

-web.jpg)