Revolutionising Plant Engineering: Festo's VZXA Modular Angle Seat Valve

In the dynamic landscape of plant engineering, the demand for flexible and high-performance solutions has never been greater. Festo, a pioneer in automation technology, meets this demand with its innovative angle seat valve VZXA. This valve, designed with flexibility and adaptability in mind, offers robust control of media flows up to 230 °C, setting a new standard in plant automation.

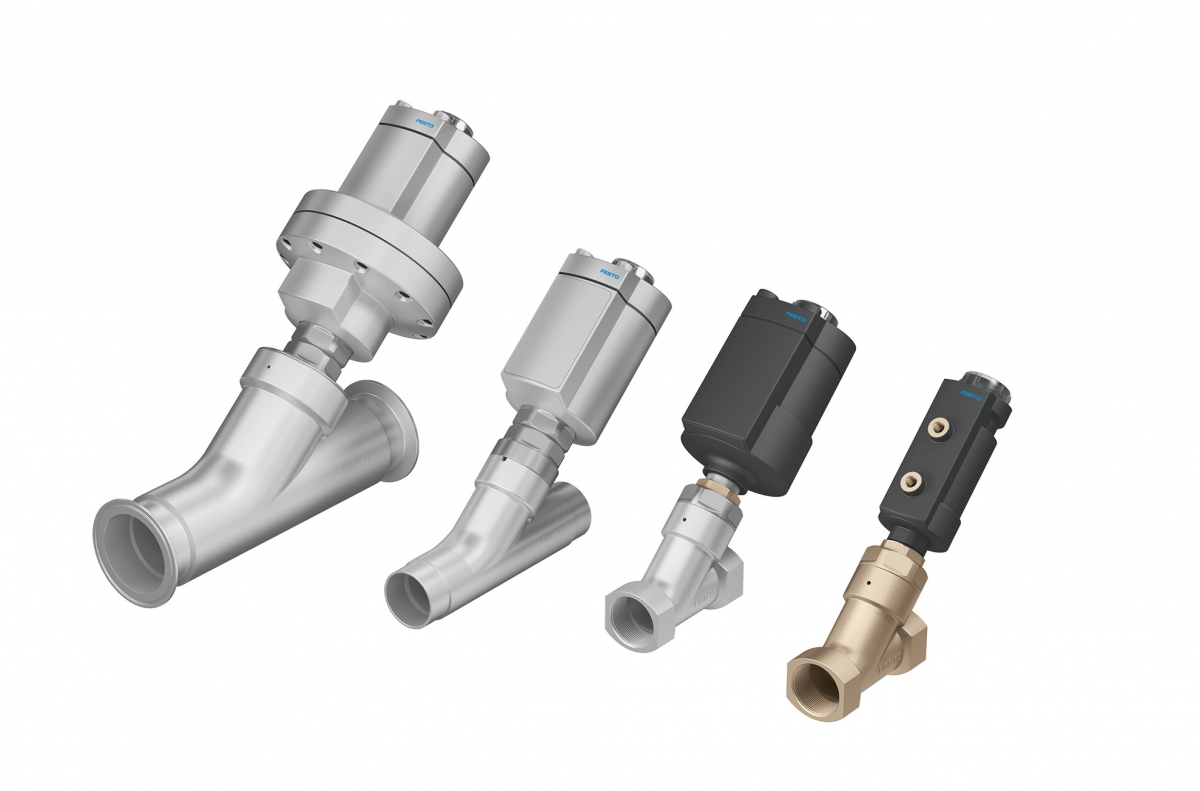

The key to the VZXA's versatility lies in its modular design and patented interface, allowing valve bodies and actuators to be seamlessly combined. This unique feature not only enhances flexibility but also introduces a hot-swap function, enabling the quick exchange of actuators or spare parts. Different actuators and valve bodies can be effortlessly integrated into various applications, providing plant engineers with a customizable and efficient solution.

Installation and maintenance are simplified with the VZXA's user-friendly interface. Actuators can be replaced without the need to open the piping, streamlining the process and saving valuable time. This advantage is particularly beneficial in areas that are hard to access, where actuators can be mounted on the valve body at the end of an assembly task.

A standout feature of the VZXA is its spindle seal, designed as a cartridge with a stainless-steel sleeve and a preloaded chevron packing seal. This innovative design ensures easy and reliable replacement without the necessity of special tools, contributing to the valve's overall durability and leak-proof performance.

Crafted from sturdy materials, the VZXA comprises an angle seat valve body, a piston or diaphragm drive, and a visual position indicator. The flow-optimized valve body, made of stainless steel, is available in various nominal widths, ensuring compatibility with diverse applications. The stainless-steel actuator, available in three sizes with control functions such as NC, NO, and DA, can operate under a maximum pressure of up to 30 bar.

In industries such as the tyre industry, the VZXA finds its niche with additional interfaces between the actuator and the process valve. This allows for the creation of custom blocks fitted with VZXA angle seat valves, saving space and enabling installation in tight spaces. These custom blocks also facilitate the handling of multiple media flows, including steam, nitrogen, or a vacuum, providing a comprehensive solution for diverse industrial applications.

In conclusion, Festo's VZXA Modular Angle Seat Valve is a game-changer in plant engineering, offering a blend of flexibility, durability, and high performance. With its innovative design and user-friendly features, it not only simplifies installation and maintenance but also provides plant engineers with a customisable solution to meet the evolving needs of modern industrial processes.

For more information visit www.festo.com/vzxa

|

Tel No: |

0800 626422 |

|

Email: |

|

|

Website: |

| Telephone: | 0800 626422 |

| Email: | info.gb@festo.com |

| Website: | www.festo.com |

| More information on the Festo Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Festo LtdIssue 90Process Valves

-web.jpg)