Steam Today and Steam Tomorrow

demonstrated by looking at some of its potential future uses.

In article 1 (Valve User Issue Eleven), the traditional uses of steam were outlined – power generation, heating, humidification, sterilization and cooking. Because steam is used in these applications in almost all manufacturing industries, any increase in global industrial output will see steam’s use continue to grow, with only direct use as a means of space heating likely to see any decline.

So the future of steam is secure and further strengthened by some of the newer applications to which this versatile medium is being applied. Here are some examples...

Transport

You may have seen a lot of publicity recently over the British-built steam car that set a new land speed record for such a vehicle of 148 mph.

Another example of the versatility of steam, but not an indicator that we’ll be driving steam powered cars like this in future. 1000 litres of water used in 25 minutes isn’t a very attractive ‘mpg’ feature! However, steam could very well have a place in transport of the future in many different ways.

In internal combustion engines, most of the energy in the fuel is lost as exhaust heat, with only a small percentage (approx 30%) used for propulsion.

Systems are being developed (and used) today to use steam to recover heat from engine exhausts. The recovered steam can be used either to drive the vehicles electrics through a turbine driven alternator, or to run refrigeration plant on trucks. This latter application is already happening on ‘reefers’ (refrigerated containers). When the vehicle is being driven, a heat exchanger on the exhaust produces steam, which is then stored in a pressure vessel. This stored steam is used to run the refrigeration plant whilst the truck is parked, resulting in less pollution and less noise, a major concern at truck stops.

This ability to store energy is also being used on locomotives. No, not a re-emergence of dirty smoky steam engines, but rather than having a fired boiler, today’s steam locomotive is simply a large pressure vessel, charged with steam when the vehicle is stationary. Once pressurised, the engine is capable of providing significant power output, over reasonable distances. A major application is on chemical plants where other forms of propulsion (electric, diesel or a conventional fired boiler) could all create an explosion hazard.

Energy Storage

Steam’s ability to store energy (as described above) means it can be used as a battery, being charged up when surplus energy is available. This could be waste heat, or energy from an intermittent supply such as wind, solar or wave power.

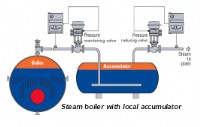

The same storage technology is used in an accumulator - a device to help smooth out fluctuations in demand in a steam system, so ensuring that the correct quality of steam is supplied at minimum stress on the boiler. Not a new technology but one with growing interest as boiler sizes reduce and their internal ability to store energy diminishes.

Cooling

It may seem strange to consider steam as a means of providing chilled water but absorption and steam jet systems both use steam to create the refrigeration effect. The steam is used in an absorption unit to heat the working solution (generally lithium bromide) to concentrate it. In a steam jet system, a steam ejector is used to create the vacuum necessary in the flash chamber.

Again, not new technologies, but with significantly increased usage of electricity to produce cooling, electrical distribution networks are struggling to cope during hot periods. In many countries, peak electrical load now occurs during summer months, not winter.

Many industrial processes involve both heating and cooling, food manufacture being a good example. Steam produced from waste heat is an economical way of providing the chilled water needed for the cooling cycle.

Steam in the Domestic Environment

Traditionally steam has been seen as very much an industrial fluid, but even today, we are seeing steam being used more in the domestic environment. One such use is steam in washing machines. The claim is that the steam reduces water consumption (a growing concern) and improves the cleaning effect, plus the finished clothes require less ironing!

Irons themselves are changing. It’s more common now to see an iron coupled to a steam generator, helping to produce more steam and speed up the ironing process. Steam is used to clean carpets and curtains, with special machines for these now readily available. It is used in steamers and steaming ovens to prevent goodness and flavour being lost from the food during traditional cooking processes such as boiling.

With such growing use, is a domestic scale, steam operated, Combined Heat and Power (CHP) system now a vision for the future?

Clean Steam

Steam’s ability to cook, sterilize and humidify means it has a significant place in modern industries such as Healthcare, Food & Beverage and Pharmaceuticals. Here the quality of the steam is important, with a growing requirement for ‘clean’ or even ‘pure’ steam. Clean steam is produced from De-Ionised or Reverse Osmosis feedwater and would be used where the steam comes into direct contact with a product or process. Pure steam is produced from even higher quality water containing no bacteria or pyrogens, being referred to as WFI (Water For Injection).

These higher grades of steam are produced from generating equipment very different from a conventional boiler, as can be seen from the illustration opposite.

Other more obscure uses

Superheated steam (steam heated above its saturation temperature) is now being used in geothermal plants as an alternative to rotary drilling. Spallation is the name of the process, where superheated steam, coming into contact with crystalline rocks, causes the grains of rock to expand and crack. Small particles, called spalls split off. Drilling to depths of 9000m is possible.

Again associated with extracting renewable energy, steam is the working fluid in OTEC applications where the temperature gradient across the ocean depths in the tropics is enough to produce energy and desalinated water.

As long ago as 1946, Sir Oliver Lyle, in his introduction to ‘The Efficient Use of Steam’, wrote,

“Steam is industry’s most wonderful, flexible and adaptable tool.” Many other ‘tools’ have emerged over the past 60 years but as we have seen, steam is still crucially important to industry due to its flexibility and adaptability. It really is a fluid of the 21st century!

Spirax-Sarco, Tel: 01242 521361

Website: www.spiraxsarco.com/uk

| Telephone: | 01242 573703 |

| Email: | UK.Enquiries@uk.spiraxsarco.com |

| Website: | spiraxsarco.com/uk |

| More information on the Spirax Sarco Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Spirax Sarco LtdIssue 13Steam SystemsMaster Class

-web.jpg)