New Era for Econosto in the UK

Significantly, early 2010 saw changes in the Aberdeen branch which brought onboard several new faces and fresh ideas for business development. One of the results of this was an agreement reached with USA company Taylor Valve Technology Inc. for Econosto UK to become the UK and European distributor of Rupture Pin Advanced Safety Relief valves.

More widely known in the US than Europe, the Rupture Pin valves represent the most up-to-date technology in safety relief valves and demonstrate significant advantages over rupture disc products. And with safety top of the industrial agenda due to accidents and natural events in the last two years it’s a product well worth taking a closer look at.

Rupture Pin – how it works

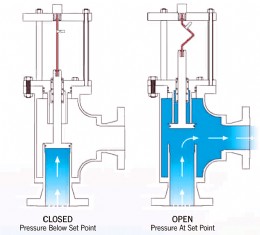

The valve works by utilising a pin (known as the buckling pin) which holds in place a piston on a seat which has a bubble-tight seal under normal operating pressures. The pin operates according to Euler’s formula that gives the maximum axial load that a long, slender, ideal column can carry without buckling. When that load is exceeded the pin buckles and relieves the pressure.

An ideal column (the pin) is one that is perfectly straight, homogeneous and free from initial stress. The maximum (or critical) load causes the pin to be in a state of unstable equilibrium, i.e. the introduction of the slightest lateral force will cause the pin to fail by buckling.

Using the formula the appropriate diameter, length and material for different pin loads can be determined and the set point accurately predicted every time. Pin dimensions are precise and the only variable will be the modulus of elasticity due to variations in ambient temperature. This is resolved by the use of materials which have minimal change in modulus of elasticity within the temperature range that the valve will operate in.

Pins are non-corrosive and will neither fatigue nor fail prematurely due to pulsation since this is prevented by the pin remaining in compression. Once buckled the valve is fully open in milliseconds.

Benefits of the new valve technology

The table above demonstrates some of the benefits of rupture pin technology over rupture discs.

Rupture Pin valves along with the other new additions to the Econosto UK product range mark a new era of opportunity for the company. Managing Director, Clive Gamble commented, “The last year and a half has seen some rapid changes at Econosto UK, which even a couple of years ago we could not have foretold. We genuinely believe the changes will not only aid the company to adapt easily to changing market conditions but also will bring benefits to our customers in the increased choice in products and services.”

Econosto UK

Tel: 0116 272 7300

Website: www.econosto.co.uk

| Telephone: | 0116 272 7300 |

| Email: | Chris.Dixon@eriks.co.uk |

| Website: | https://eriks.co.uk/en/ |

| More information on the Eriks Industrial Services Ltd BVAA Member Directory Page |

Search related valve / actuator articles: Eriks Industrial Services LtdIssue 18Valves

-web.jpg)